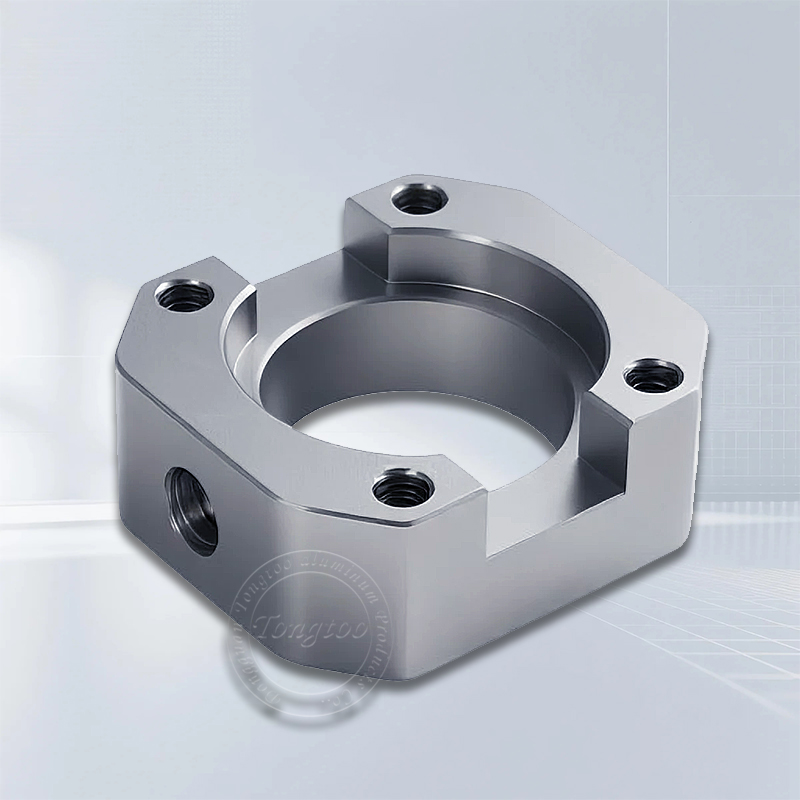

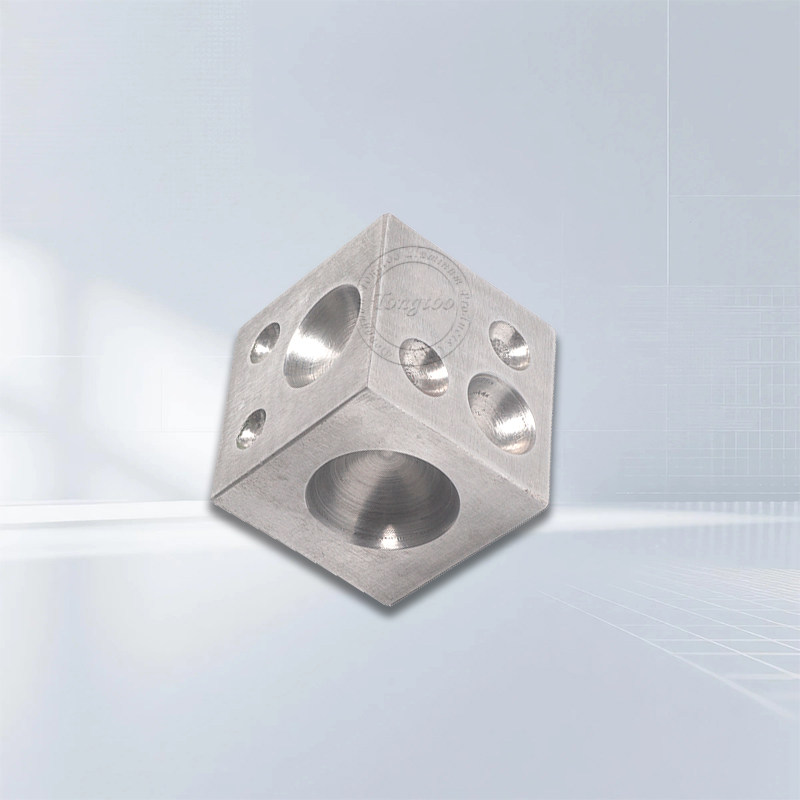

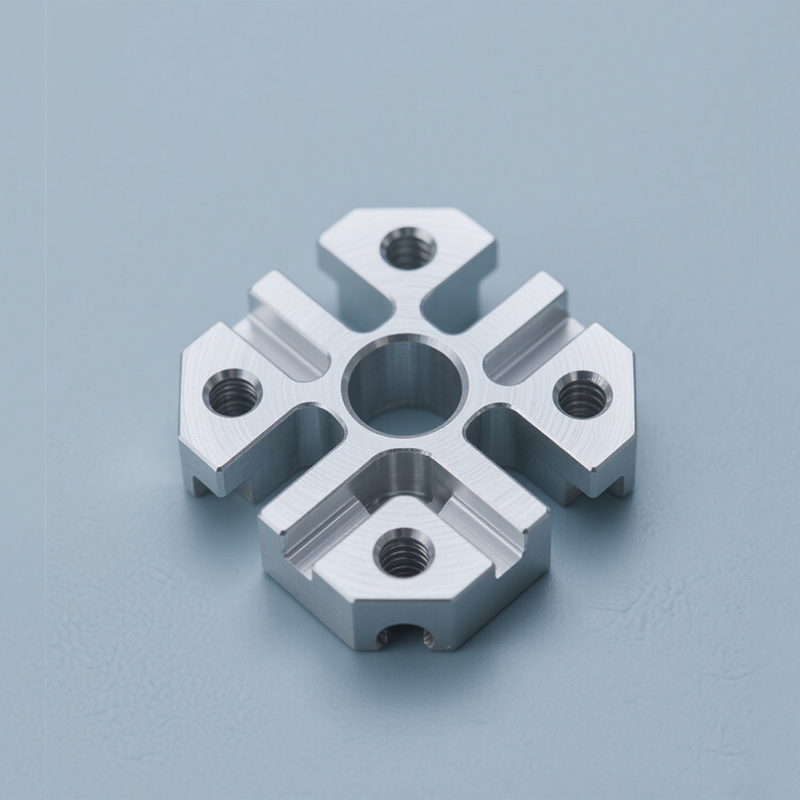

Precision CNC Parts with 5-Axis Machining Service

Our CNC precision parts service specializes in providing high-precision, high-complexity, and high-quality customized metal and non-metal parts for a wide range of industries. Leveraging advanced multi-axis CNC machines, sophisticated craftsmanship, and a strict quality management system, we transform your design blueprints into high-performance, dimensionally accurate parts. We are your reliable partner for prototyping and mass production.

Product Description

Product Introduction

Our CNC precision parts service specializes in providing high-precision, high-complexity, and high-quality customized metal and non-metal parts for a wide range of industries. Leveraging advanced multi-axis CNC machines, sophisticated craftsmanship, and a strict quality management system, we transform your design blueprints into high-performance, dimensionally accurate parts. We are your reliable partner for prototyping and mass production.

Product Parameters

Product Name: CNC Precision Parts

Material: Aluminum alloy, stainless steel, titanium alloy, copper, die steel, PEEK, etc.

Processing: CNC machining/milling/stamping/die-casting

Surface Treatment: Anodizing/hard anodizing/powder coating/laser engraving

Product Features: Customizable openings, dimensions, and logos are supported.

Product Features and Applications

Core Features and Benefits:

Excellent Precision: We strictly adhere to customer drawings, with standard tolerances of ±0.01mm and ultra-high micron-level precision, ensuring a perfect fit.

Wide Range of Materials: We can process a wide range of metals (such as aluminum alloys, stainless steel, titanium alloys, copper, and mold steel) and engineering plastics (such as PEEK) to meet varying strength, hardness, corrosion resistance, and special working conditions.

Versatile Process Capabilities: We support a variety of process combinations, including milling, turning, boring, and drilling, to easily handle the machining challenges of complex geometries, internal cavities, threads, and thin-walled structures.

Strict Quality Control: From raw material storage to finished product shipment, we implement the ISO 9001 quality management system throughout the entire process. We are equipped with professional inspection equipment such as coordinate measuring machines (CMMs) and optical image measuring machines to ensure that every product meets specifications.

Flexible Batch Size: Whether you need a single prototype or large-scale production of over 10,000 pieces, we offer highly competitive solutions and pricing.

Applications:

Automotive Industry: Engine peripheral parts (brackets, housings), sensor housings, chassis components, new energy vehicle battery pack components/end plates, charging cable components, and interior trim. Industrial Equipment: Automated robot joints, precision transmission components, precision instrument brackets and housings, sensor bases, fixtures, guide rails and sliders, cylinder components, and connectors.

Aerospace: Drone fuselages, satellite components, avionics equipment brackets, and lightweight structural parts.

Energy: Oil and gas exploration equipment parts, wind turbine components, and fuel cell bipolar plates.

Consumer Electronics: Mobile phone/tablet midframes and structural components, laptop casings, camera parts, audio components, smart wearable device brackets, and radiators.

Optical and Medical Equipment: Lens barrels, lens mounts, laser housings, medical device housings, brackets, and handles.

Communications Equipment: 5G base station antenna covers, filter housings, RF device housings, and heat sinks.

Photographic Equipment: Gimbal components, camera grips, lens accessories, and lighting brackets.

Models and Sports Equipment: Bicycle parts (brake handles, pivot points), model airplane parts, and high-end sports equipment accessories.

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (EU Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production Process Quality Control)

Testing Equipment: Zeiss 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

|

|

|

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive customized services tailored to customer needs.

Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/PEF + wooden box

FAQ

Q: What design file formats do you support?

A: We support multiple major formats, including 3D model files such as STEP, IGES, XT (Parasolid), and SLDPRT, as well as 2D engineering drawing files such as PDF and DWG.

Q: How long does it take from order placement to sample delivery?

A: Production lead time depends on the complexity and quantity of the parts. Prototyping for simple parts typically takes 3-7 business days. For mass production, please consult our sales team for specific schedules.

Q: How do you ensure consistent quality during mass production?

A: We ensure consistent mass production through standardized operating procedures (SOPs), first article inspection (FAI), in-process quality control (IPQC), and final article inspection. All processing equipment undergoes regular maintenance and precision calibration.

Q: Do you provide surface treatment services?

A: Absolutely. We offer a wide range of post-processing options, including anodizing (with our own anodizing workshop), electroplating, sandblasting, polishing, passivation, and painting, to meet your requirements for corrosion resistance, aesthetics, and special features.