Cnc Aluminum Extruded Profiles

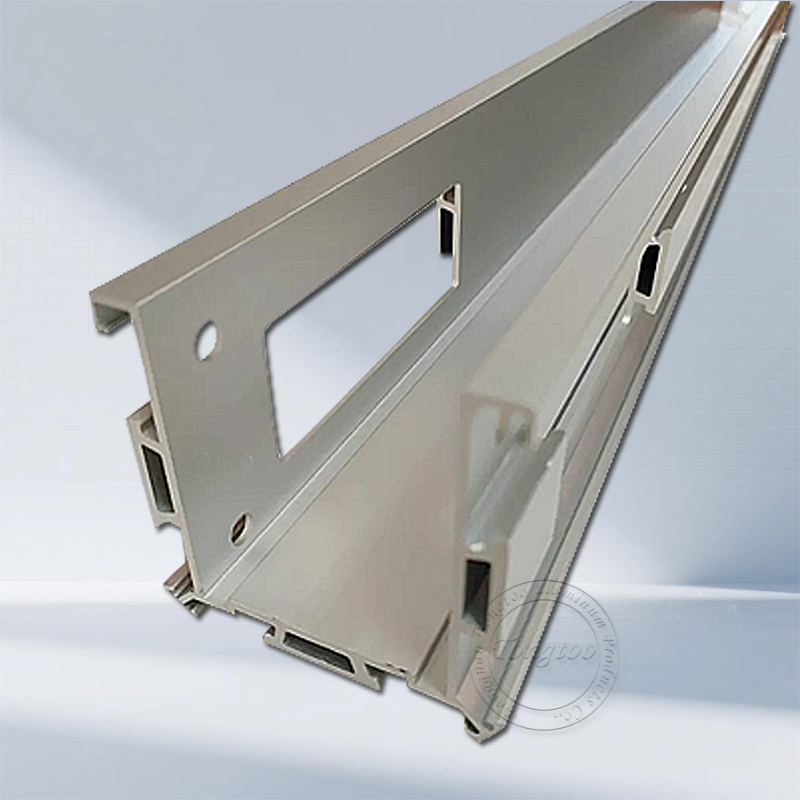

Our CNC aluminum extrusion profiles utilize high-precision CNC machining equipment, enabling processing techniques such as T-slots, irregular shapes, precision drilling, bevel cutting, and bending.

Product Description

Cnc Aluminum Extruded Profiles

CNC Aluminum Extrusion Profiles: Custom Processing and Full-Chain Services

Dongguan Tongtoo Aluminum Products Co., Ltd. specializes in providing customized CNC aluminum extrusion profile services, covering the entire process from aluminum profile mold research and development and design to extrusion production and anodizing. We focus on creating precision aluminum profile products that meet the needs of customers in various industries. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have introduced German imported equipment, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. With exquisite craftsmanship, rapid response, and comprehensive quality control, we provide customized ODM/OEM solutions for global customers, striving to become a trusted strategic partner in the international industrial manufacturing field.

Product Core Parameters and Processing Capabilities

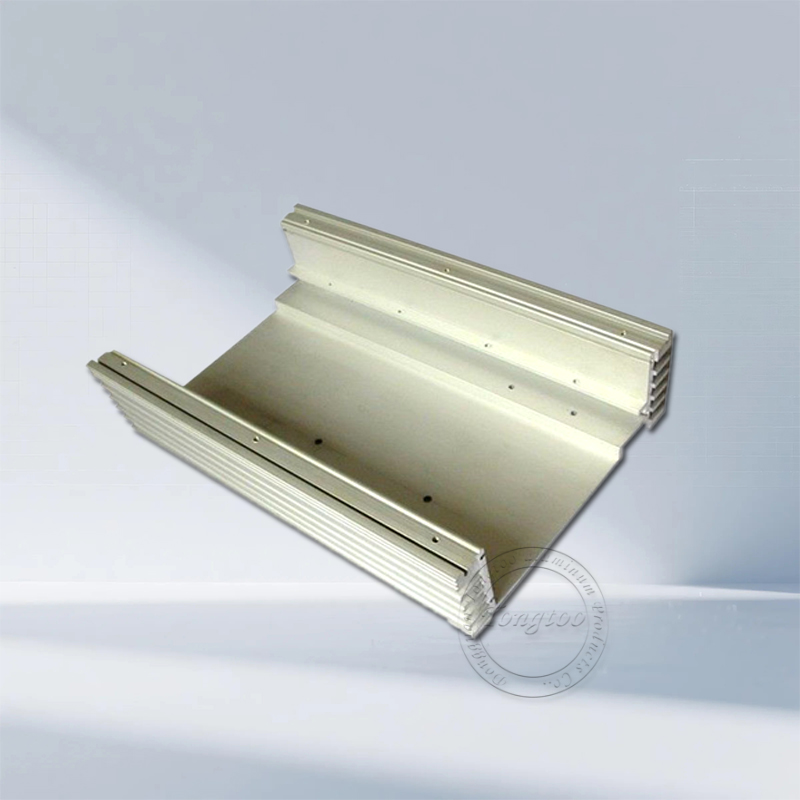

Our CNC aluminum extrusion profiles utilize high-precision CNC machining equipment, enabling processing techniques such as T-slots, irregular shapes, precision drilling, bevel cutting, and bending. Dimensional tolerances are controlled within ±0.1mm, precisely matching customer drawings. Commonly used aluminum alloy grades include 6063-T6 and 6061-T6, possessing excellent strength-to-weight ratios, balancing lightweight design with structural stability, and meeting the needs of industrial automation, 3D printer parts, LED heat sinks, and other applications.

The profile processing range covers a minimum outer diameter of 10mm to a maximum outer diameter of 350mm, with a minimum wall thickness of 0.7mm (adjustable according to product structure). We support both mass extrusion production and small-batch customization, with flexible minimum order quantities to suit different customer needs. From sample prototyping to mass delivery, we can efficiently complete all stages.

Full-Chain Service Process: One-Stop Solution

As a manufacturer integrating mold design, extrusion production, and anodizing, we eliminate intermediate steps, providing customers with a worry-free, full-process service:

1. Aluminum Profile Mold Design: Based on customer drawings and application scenarios, our professional team designs customized molds with precise tolerances, ensuring that the extruded profiles meet expectations. The molds are highly durable and suitable for large-volume production needs.

2. Aluminum Profile Extrusion Production: Aluminum ingots are heated to a malleable state at 400-500℃ and extruded through custom molds. Subsequent processes include quenching, stretching, and cutting to correct profile bending and internal stress, ensuring the straightness and structural strength of the profiles.

3. CNC Precision Machining: The extruded profiles undergo precision machining using CNC drilling, milling, and cutting to accurately create assembly holes, slots, and other structures, meeting the requirements for direct assembly. This is widely used in electronic enclosures, industrial frames, and automotive parts.

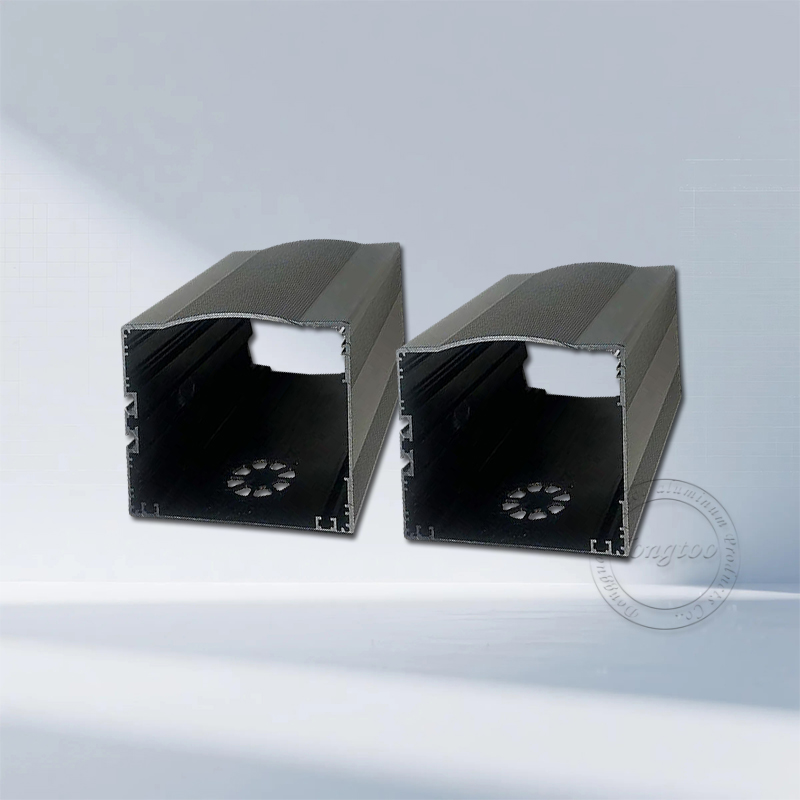

4. Anodizing Surface Treatment: We offer anodizing services in various colors, including silver and black, to enhance the corrosion resistance and surface hardness of the profiles. Additional processes such as laser engraving of logos and powder coating are also available, ensuring both practicality and aesthetics.

Product Application Scenarios

Thanks to its excellent processing performance and comprehensive quality control, this CNC aluminum extruded profile has been widely used in various industries:

Industrial Automation: T-slot aluminum profile frames, conveyor accessories, robot end effector structural components;

Electronic Equipment: LED heat sinks, touch screen frames, sensor housings, 3D printer 2020/2040 series profiles;

Automotive and New Energy: Battery tray accessories, lightweight structural components, solar panel bracket profiles;

General Machinery: Instrument and meter housings, equipment guardrails, custom-shaped structural components.

Product Qualification

Environmental Certification:

RoHS certification (lead-free, cadmium-free, etc.)

REACH (EU chemical safety standard)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (production process quality control)

Testing Equipment: Zeiss 3D scanner (accuracy 0.8μm)

Delivery, Shipping and Serving

As a professional ODM&OEM manufacturer with over 20 years of precision machining experience, we prioritize customer needs and provide comprehensive customized services. Standard Packaging: Copy paper + cardboard box

Custom Packaging: Blister tray/EPE foam + wooden box

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), turning-milling composite CNC lathes, CNC lathes, milling machines, grinding machines, etc.; as well as more than a dozen various inspection equipment (detection accuracy up to 0.001 MM). Our machining capabilities reach internationally advanced levels. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts that support industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with exceptional precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.