CNC Machining Parts for Furniture Hardware OEM

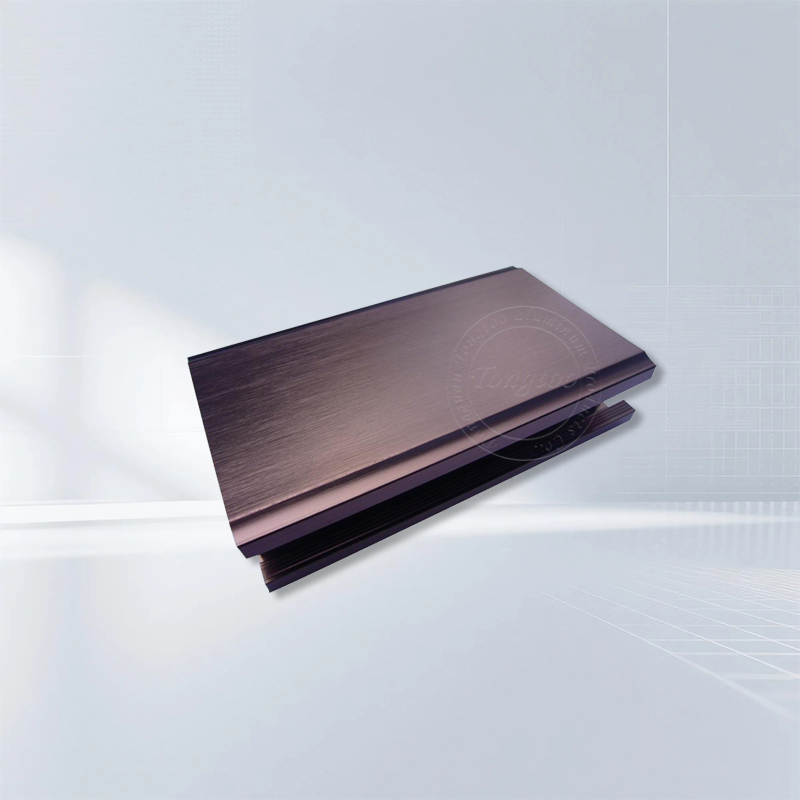

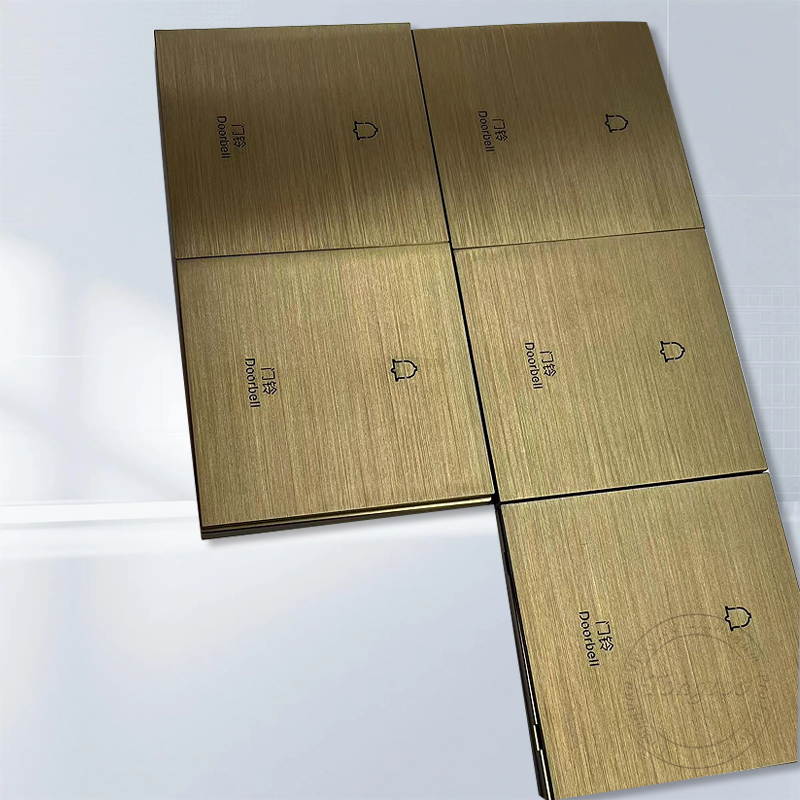

We specialize in high-quality CNC machining services for home accessories, mainly producing customized metal accessories such as aluminum alloy door and window handles, cabinet handles, decorative strips, smart doorbell panels, and switch panels.

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. is a professional enterprise specializing in CNC precision machining, injection molding, mold development, and metal manufacturing of aluminum alloys. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have introduced imported German equipment, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. We focus on exquisite craftsmanship, rapid response, and comprehensive quality inspection to provide customized ODM/OEM solutions for global clients, striving to become a trusted strategic partner in the international industrial manufacturing field.

Product Introduction:

We specialize in high-quality CNC machining services for home accessories, mainly producing customized metal accessories such as aluminum alloy door and window handles, cabinet handles, decorative strips, smart doorbell panels, and switch panels. Using high-quality aluminum alloys such as 6063/6061/7075, combined with CNC precision machining and anodized surface treatment, we ensure that our products are both aesthetically pleasing and durable. We support personalized designs, customizing sizes, shapes, and surface colors according to home styles to meet the modern pursuit of detail and quality.

Core Technologies:

Precision Machining and Consistency:

CNC machining ensures ±0.05mm precision, guaranteeing uniform dimensions and error-free assembly for each batch of handles and decorative strips.

High Strength and Lightweight:

The aluminum alloy material achieves lightweight design while maintaining load-bearing strength (e.g., cabinet handles can support ≥50kg), preventing sagging and deformation of furniture components.

Multiple Surface Finishes:

Anodizing offers a variety of colors including black, silver, gold, and gray, with a surface hardness of HV400 or higher, making it scratch-resistant and wear-resistant. Sandblasting and brushed finishes are also supported.

Personalized Customization Support:

Design drawings can be provided or design optimizations can be offered. Flexible small-batch production is supported, with samples shipped in as little as 5 days.

Environmentally Friendly and Safety Compliant:

Complies with RoHS standards, with no heavy metal leaching.

Application Areas

Door and Window Systems: Casement window handles, sliding door handles, folding door accessories

Cabinets and Storage: Drawer handles, cabinet knobs, wardrobe handles

Decorative Components: Wall trim strips, furniture edging strips, decorative panels

Smart Home Integration: Smart doorbell panels, aluminum switch panels, smart lock housings

Product Qualifications

Environmental Certifications:

RoHS Certification (Lead-free, Cadmium-free, and other hazardous substances-free)

REACH (EU Chemical Safety Standard)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production process quality control)

Testing Equipment: 3D scanner (0.8μm accuracy)

Deliver, Shipping, and Serving

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive customized services based on customer needs.

Standard Packaging: Copy paper + cardboard box

Custom Packaging: Blister tray/EPE foam + wooden crate

Global Export Experience: Familiar with international packaging and transportation standards, stable product supply to global markets such as Europe, America, Japan, and South Korea.

FAQ

Q1: Are cabinet handles fingerprint-resistant and grease-resistant?

High-density anodized layer, oleophobic and hydrophobic surface, easy to clean with a damp cloth, and fingerprints are not easily left behind after long-term use.

Q2: Can colors and logos be customized to match home decor styles?

Supports Pantone color selection, and logos or patterns can be added via laser engraving to meet brand home decor needs.

Q3: How does the smart doorbell panel ensure signal transmission?

The panel structure has a reserved signal window, using high-quality aluminum alloy to ensure stable WIFI/Bluetooth signal penetration.

Q4: What is the minimum order quantity? What is the production cycle?

Minimum order quantity is 1 piece. Sample cycle is 5-7 days, bulk orders 10-15 days.

Welcome to provide drawings for consultation. We will provide specific processing solutions and quotations based on your needs.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), CNC lathes, milling machines, lathes, grinders, etc.; and more than a dozen inspection equipment (inspection accuracy up to 0.001 MM), achieving internationally advanced machining capabilities. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts supporting industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with superior precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.