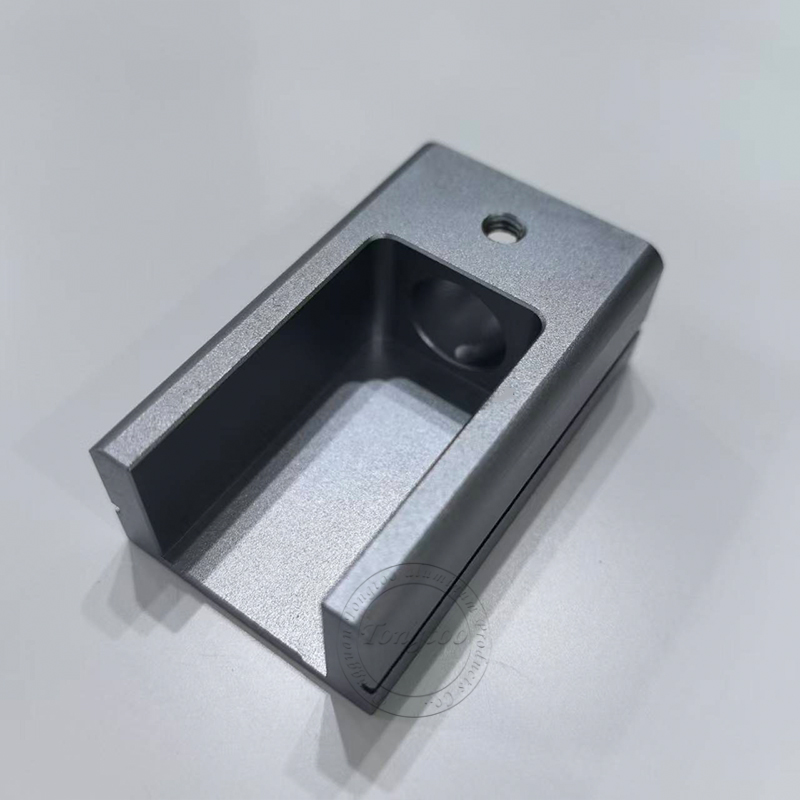

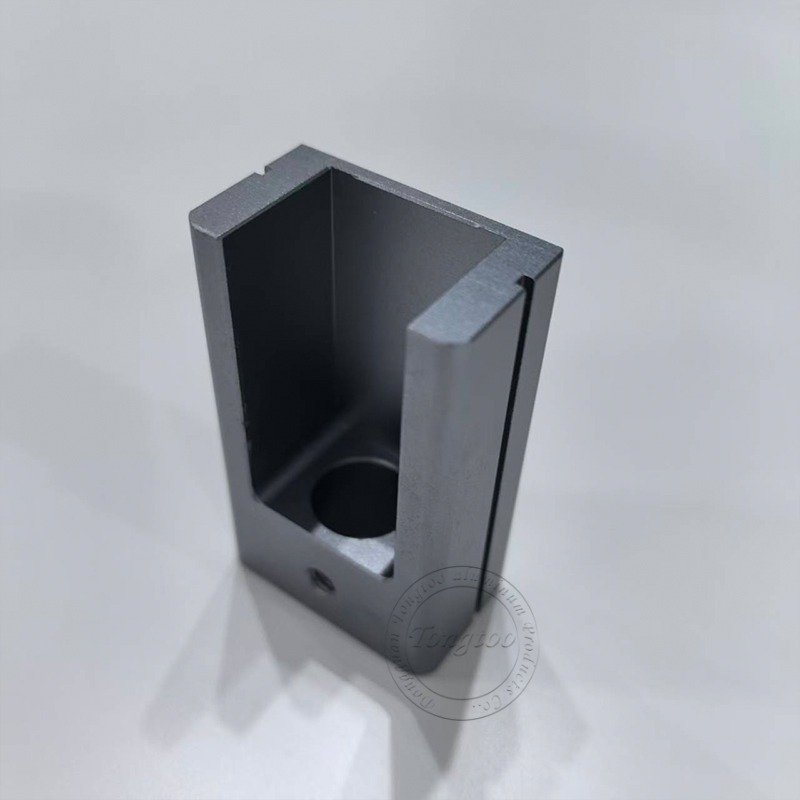

CNC Machined Parts

As a leading one-stop precision parts supplier, we specialize in providing customized CNC parts manufacturing services to our customers, from design optimization and multi-process composite machining to complete assembly.

Product Description

Professional CNC Machined Parts Manufacturer.One-Stop Precision Machining Solutions for Complex Structural Components

Product Details

As a leading one-stop precision parts supplier, we specialize in providing customized CNC parts manufacturing services to our customers, from design optimization and multi-process composite machining to complete assembly. We integrate advanced processes such as 3-axis/5-axis CNC milling, multi-axis precision turning, wire EDM, and grinding, handling a wide range of materials including aluminum alloys, stainless steel, titanium alloys, and mold steel. We are committed to transforming complex designs into highly reliable physical parts, covering the entire chain of needs from prototype verification to small and medium-batch production.

Key Product Features

Integrated Forming Capability for Complex Structures

With 3-5 axis linkage machining centers, we can easily handle challenging geometric structures such as deep cavities, irregular curved surfaces, complex thin walls, and undercuts, achieving one-time clamping and forming of multi-faceted parts, ensuring excellent geometric tolerances and structural integrity. We specialize in machining non-standard structural components such as housings, brackets, bases, cavities, and tooling fixtures.

What materials can we machine?

Metal materials (most common applications) Common metals: aluminum, steel (including stainless steel), brass, copper.

Lightweight/high-strength metals: titanium alloys (used in aerospace, medical).

What parts can we machine?

This is where the true power of CNC machining lies. From simple functional parts to extremely complex geometries, anything is possible:

High-precision functional parts: engine blocks, gears, drive shafts, hydraulic components, precision molds (injection molds, die-casting molds).

Complex contours and surfaces: aircraft structural components, turbine blades in the aerospace field; artificial joints, surgical instruments in medical devices;

Personalized parts in the automotive modification field.

Prototypes and models: Rapid and accurate production of product functional prototypes (mock-ups) for design verification.

Electronic and communication components: metal frames for mobile phones/computers, heat sinks, RF cavities, waveguides.

Everyday items: musical instrument parts, high-end kitchenware, jewelry, musical instruments, and even artistic sculptures.

Main application

New energy and semiconductor equipment: battery module end plates, fuel cell bipolar plates, semiconductor equipment cavities, wafer carriers, heat dissipation modules. Optics and Precision Instruments: Lens barrels, laser housings, optical adjustment frames, experimental instrument frames, sensor mounting bases.

Communications and Data Centers: 5G filter cavities, waveguide components, server cooling plates, precision components for fiber optic connectors.

High-End Consumer Electronics: Drone fuselage structural components, AR/VR device frames, camera gimbal components, core structural components for smart home devices.

Special Vehicles and Robotics: Autonomous driving sensor brackets, robot joint housings, special equipment connectors, shock absorption components.

Certifications:

RoHS certification (lead-free, cadmium-free, etc.)

REACH (EU chemical safety standard)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (production process quality control)

Testing Equipment: 3D scanner (accuracy 0.8μm)

Delivery, Shipping and Serving

Professional ODM & OEM manufacturer with over 20 years of precision machining experience, customer-oriented, providing comprehensive customized services.

Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/pearl cotton + wooden box

Global Export Experience: Familiar with international packaging and transportation standards, stable product supply to Europe, America, Japan, South Korea and other global markets.

FAQ

Q: What is the minimum order quantity?

A: We support small batch customization, with a minimum order quantity as low as 1 piece, suitable for R&D prototyping and small batch production.

Q: What is the achievable machining accuracy?

A: The conventional machining accuracy is ±0.05mm, and high-precision requirements can reach ±0.01mm, depending on the part structure and size.

Q: What surface treatment options are available?

A: We offer various surface treatment processes, including anodizing (various colors), sandblasting, polishing, and conductive oxidation.

Q: How long is the production cycle?

A: Samples take 3-7 days, small batch production takes 7-15 days, and large batch orders are determined based on the specific quantity.

Q: How do you ensure the security and confidentiality of our design drawings and technical information?

A: We highly value the protection of our customers' intellectual property. All client files are transmitted and stored through an encrypted system, and legally binding non-disclosure agreements (NDAs) can be signed with clients. Project execution uses code management, with access limited to necessary personnel, ensuring information security through both institutional and technical measures.

We welcome inquiries regarding drawings, and we will provide specific processing solutions and quotations based on your needs.

Company Introduction:

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), turning-milling composite CNC lathes, CNC lathes, milling machines, grinding machines, etc.; as well as more than a dozen various inspection equipment (detection accuracy up to 0.001 MM), achieving internationally advanced mechanical processing capabilities. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts that support the aerospace, automotive, military, medical, machinery, electronics, and communications industries. We are committed to innovation, manufacturing and assembling critical components with exceptional precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.