Precision Cavity Milling Services for Industrial Components

Dongguan Tongtoo Precision specializes in providing precision cavity milling services, possessing a 4500/2500 large four-axis CNC machine and multiple medium and small CNC machines. We excel in deep cavity milling and five-sided machining of mold cavities, box-type parts, and large cavities, ensuring high precision and high efficiency. Free inquiry, fast delivery!

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. is a professional enterprise specializing in CNC precision machining, injection molding, mold development, and metal manufacturing of aluminum alloys. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have imported equipment from Germany, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. We focus on exquisite craftsmanship, rapid response, and comprehensive quality inspection to provide customized ODM/OEM solutions for global clients, striving to become a trusted strategic partner in the international industrial manufacturing field.

Product Introduction

Dongguan Tongtoo Precision specializes in providing precision cavity milling services, possessing a 4500/2500 large four-axis CNC machine and multiple medium and small CNC machines. We excel in deep cavity milling and five-sided machining of mold cavities, box-type parts, and large cavities, ensuring high precision and high efficiency. Free inquiry, fast delivery!

Professional Precision Cavity Milling Services – Meeting Your Comprehensive Needs from Large to Medium-Sized Complex Cavities

Our powerful production capacity of 4500mm & 2500mm large four-axis CNC machining centers, combined with extensive experience in deep cavity machining and mold manufacturing, provides you with high-precision, high-efficiency one-stop cavity milling solutions.

Our Core Equipment and Machining Capabilities (Keywords: CNC Machining Center, Large Four-Axis, Deep Cavity Milling)

We possess a complete equipment matrix, comprehensively covering your different sizes and precision requirements: Large Cavity Machining Line

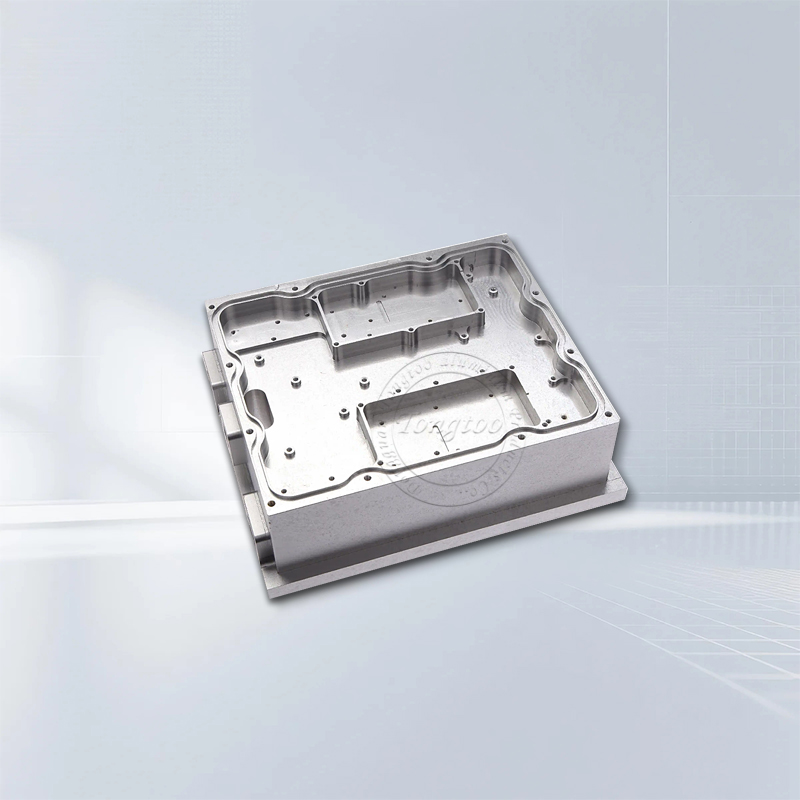

4500mm Large Four-Axis CNC Machining Center: Designed specifically for ultra-large mold cavities, machine tool beds, large equipment housings, etc., solving your pain point of "nowhere to machine large workpieces".

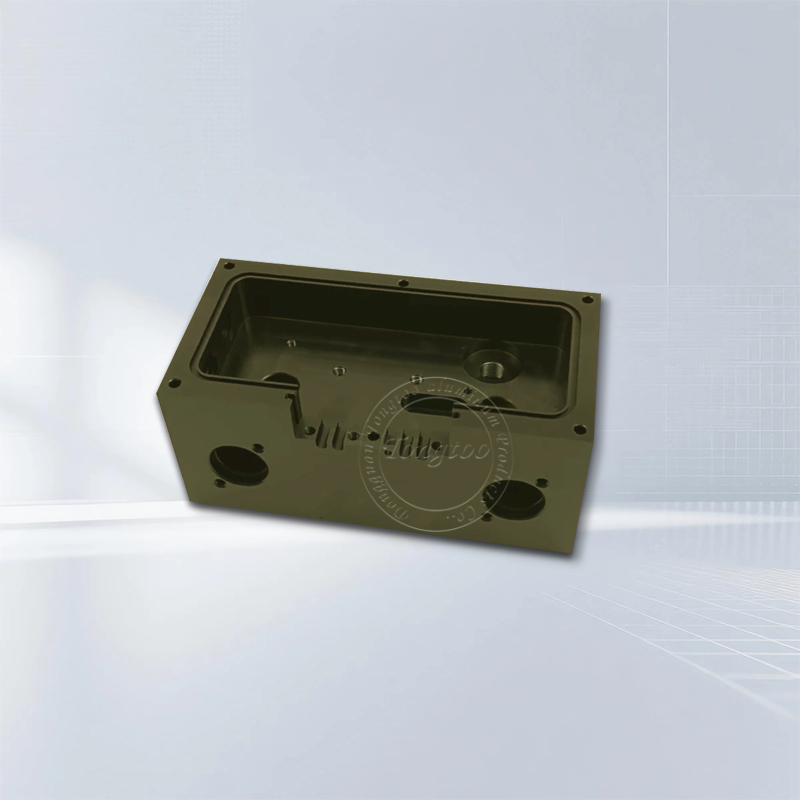

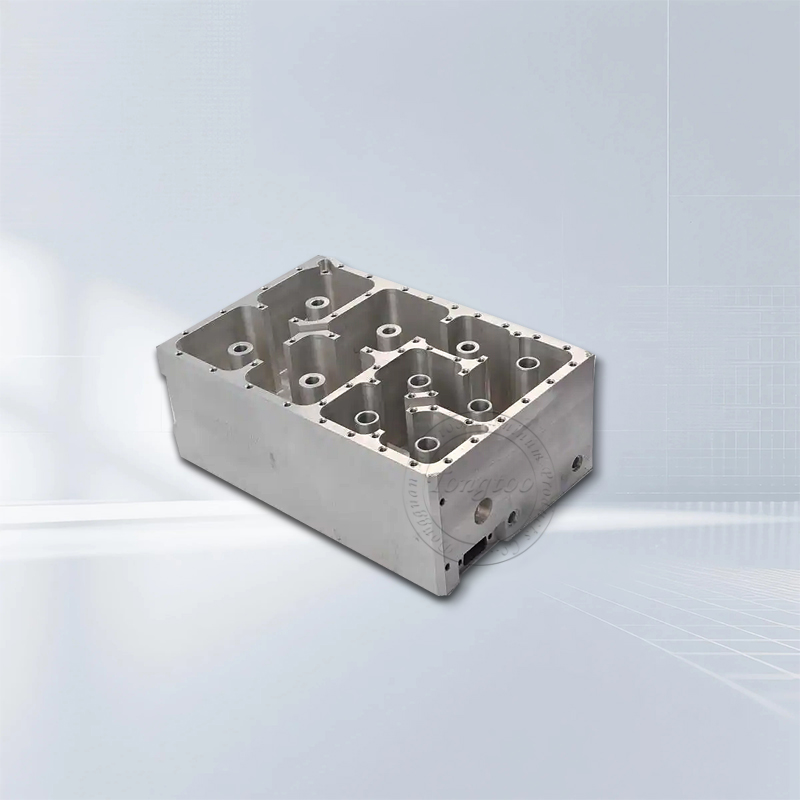

2500mm Large Four-Axis CNC Machining Center: Suitable for efficient roughing and precision milling of automotive molds, die-casting mold cavities, and large box-type parts.

Specialized Line for Small and Medium-Sized Precision Cavities: Multiple small and medium-sized CNC machining centers specialize in high-precision, high-surface-finish machining of small and medium-sized cavities, such as precision molds, medical device cavities, and electronic fixtures.

Our Unique Advantages:

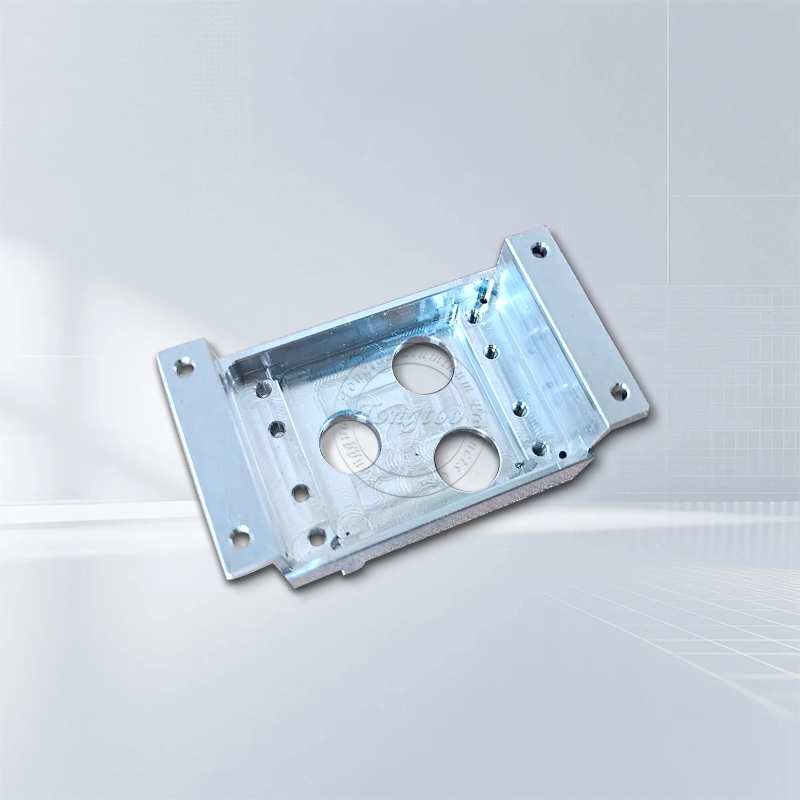

Four-Axis Simultaneous Machining:Completes multi-face machining in a single setup, reducing repetitive positioning errors and improving machining efficiency. Particularly suitable for five-sided machining of box-type parts.

Powerful Deep Cavity Milling Capabilities:Leveraging long-bladed cutting tools and stable machine tool rigidity, we excel at handling difficult-to-machine structures such as deep cavities and narrow grooves, ensuring sidewall perpendicularity and bottom surface flatness.

Large Load Capacity Worktable:Easily handles large workpieces weighing several tons, guaranteeing absolute stability during machining.

Application Areas

Mold Manufacturing:Mold cavities, die-casting mold cavities, stamping mold bases

Industrial Components:Equipment housings/frames, gearbox housings, valve bodies, aerospace structural components, automated equipment bases and cavities, etc.

Why Choose Our Cavity Milling Service?

Precision Guarantee: A rigorous quality control system, employing precision testing equipment such as coordinate measuring machines, ensures that the dimensional and geometric tolerances of every cavity conform to the drawing requirements.

Fast Delivery: A powerful equipment fleet and production scheduling capabilities support rapid prototyping and small-batch production, ensuring your project schedule is never delayed.

Expert Technology: Our engineering team possesses years of CNC programming and machining experience, enabling us to optimize machining processes and solve technical challenges such as non-standard customization and complex surface machining.

Cost Optimization: Through rational toolpath planning and efficient roughing strategies, we save you machining time and production costs.

Product Qualification

Environmental Certifications:

RoHS Certification (Lead-free, Cadmium-free, and other hazardous substances-free)

REACH (EU Chemical Safety Standard)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production process quality control)

Testing Equipment: 3D scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

Professional ODM & OEM manufacturer with over 20 years of precision machining experience. We prioritize customer needs and provide comprehensive customized services.

|

|

|

Standard Packaging: Copy paper + cardboard box

Custom Packaging: Blister tray/EPE foam + wooden crate

Global Export Experience: Familiar with international packaging and transportation standards, our products are stably supplied to global markets including Europe, America, Japan, and South Korea.

FAQ

Q1: My product has a complex structure with deep cavities and thin walls. Can you guarantee the machining precision?

A: Of course! Handling complex structures is our specialty. For deep cavity machining: Our equipment is highly rigid and equipped with long-bladed cutting tools and a professional cooling and chip removal system, effectively ensuring machining efficiency, sidewall perpendicularity, and bottom surface finish for deep cavities.

For thin-walled and complex curved surfaces: Our experienced engineers effectively control machining deformation and ensure final dimensional accuracy by optimizing CNC programming strategies (such as using small depths of cut and high-speed light cutting) and clamping schemes. We are equipped with a coordinate measuring machine to rigorously inspect all critical dimensions, ensuring 100% qualified delivery.

Q2: What specific benefits does "four-axis simultaneous machining" offer for my box-type parts?

A: "Four-axis simultaneous machining" brings you both increased efficiency and precision. For box-type parts that require machining multiple surfaces, traditional three-axis machine tools require multiple re-clampings, while our four-axis CNC can complete the machining of all four surfaces except the bottom surface in a single clamping. This brings two core advantages: Reduced repetitive positioning errors: Avoiding the cumulative errors caused by multiple clampings, resulting in higher overall part positional accuracy. Significantly Improved Processing Efficiency: Reduced clamping and alignment time shortens the entire manufacturing cycle, saving you time and costs.

Q3: I'd like to make a prototype or sample first. Do you accept small batch or sample orders?

A: Yes! We highly welcome and value rapid prototyping and small batch orders. Our comprehensive equipment fleet (including multiple small and medium-sized CNC machining centers) can be flexibly deployed to quickly respond to your prototyping needs. We understand that prototyping is a crucial step in project success, and we will provide you with high-precision samples with the same professional attitude to help your project move forward quickly.

Q4: What materials do you usually process? How efficient is your aluminum parts processing?

A: We process a wide range of materials, including: Metals: various steels, aluminum alloys (such as 6061, 7075), copper alloys, etc. We have extensive experience and highly efficient solutions, especially in aluminum parts processing. By using specialized tools and optimized cutting parameters, our equipment achieves extremely high material removal rates, significantly shortening your delivery time while ensuring surface finish and precision. Q5: My part is a non-standard design. Can you complete non-standard customization?

A: Absolutely! Our core service is precision machining of non-standard parts. Our engineering team excels at handling various complex and unconventional part designs. Please feel free to provide your 3D drawings and technical requirements. We will conduct a professional process review and provide feasible machining solutions and technical suggestions to ensure your design is accurately translated into a physical product.

Q6: How long does the entire process take from inquiry to delivery?

A: Delivery time depends on the size, complexity, and quantity of the parts. Generally, our process is very efficient:

Q: After receiving your clear drawings and technical requirements, we promise to provide a detailed quotation within 24 hours.

Production: For sample orders, we strive to complete them within 3-7 days; for bulk orders, we will provide an accurate delivery date after assessing the specific process and ensure on-time delivery through efficient production scheduling.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), CNC lathes, milling machines, lathes, grinders, etc.; and over a dozen inspection equipment (inspection accuracy up to 0.001 MM), achieving internationally advanced machining capabilities. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts supporting industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with superior precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.