OEM CNC Machining Parts for Furniture Hardware

We specialize in CNC machining and manufacturing of furniture accessories, providing reliable aluminum parts production services to our clients. We possess a 4500 heavy-duty CNC machining center and four-axis simultaneous machining capabilities, focusing on the production and customization of various aluminum alloy furniture accessories.

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. is a professional enterprise specializing in CNC precision machining, injection molding, mold development, and metal manufacturing of aluminum alloys. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have imported equipment from Germany, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. We focus on exquisite craftsmanship, rapid response, and comprehensive quality inspection to provide customized ODM/OEM solutions for global clients, striving to become a trusted strategic partner in the international industrial manufacturing field.

Product Introduction

We specialize in CNC machining and manufacturing of furniture accessories, providing reliable aluminum parts production services to our clients. We possess a 4500 heavy-duty CNC machining center and four-axis simultaneous machining capabilities, focusing on the production and customization of various aluminum alloy furniture accessories.

Core Advantages

Stable Machining Capacity: Equipped with a 4500 large CNC machining center and medium and small CNC machining equipment, our machines offer excellent stability, suitable for long-term continuous machining, ensuring consistent quality in mass production.

Multi-faceted Machining Advantage: Our four-axis simultaneous machining capability allows for multi-angle machining of complex accessories, reducing repetitive clamping and improving machining accuracy and efficiency.

Professional Aluminum Material Machining: Familiar with the properties of various aluminum alloy materials, we can select appropriate materials according to different accessory requirements and provide professional machining advice.

Comprehensive Quality Control: From raw materials to finished products, we implement strict quality inspections, equipped with standard testing equipment, to ensure that accessory dimensions meet drawing requirements.

Specifications

Materials: Commonly used aluminum alloys such as 6061 and 6063

Machining Accuracy: ±0.1mm

Surface Treatment: Supports anodizing, sandblasting, and other post-processing

Production Mode: Supports small-batch trial production and mass production

Application Areas

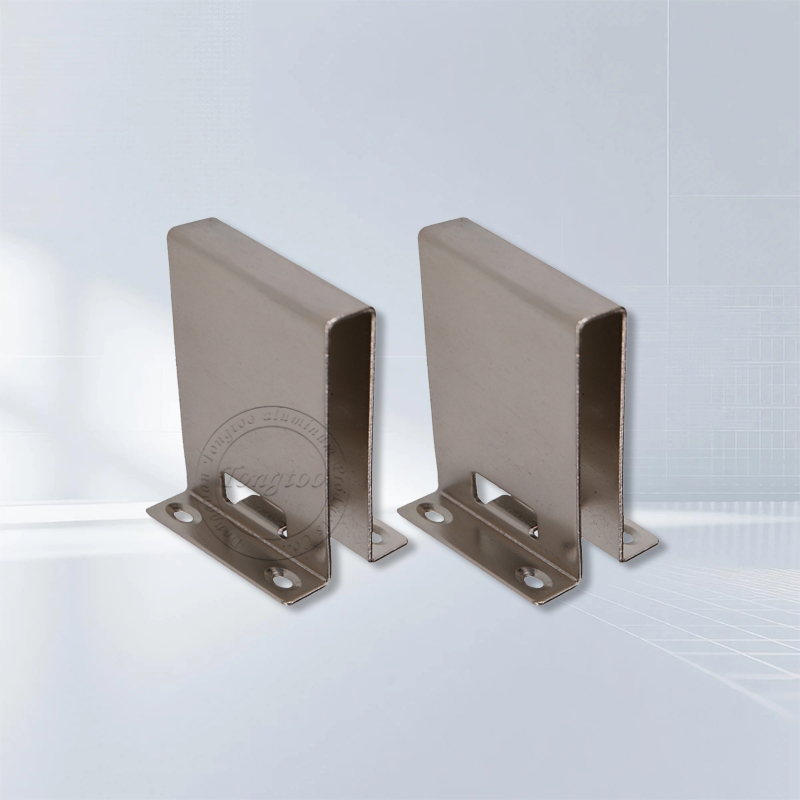

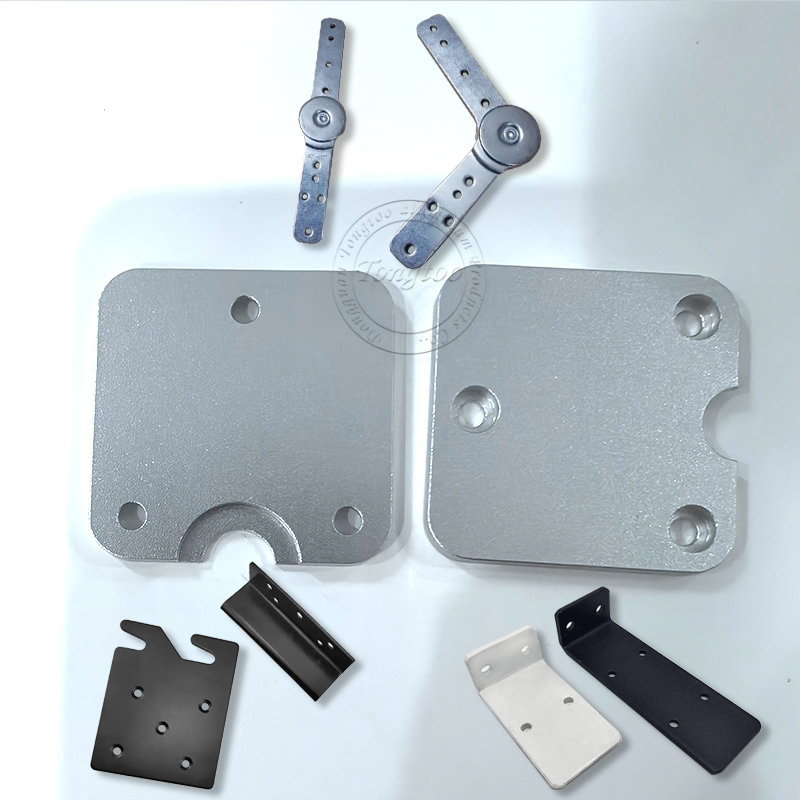

Furniture Structural Components: Table legs, brackets, crossbeams, corner brackets, etc.

Connecting Accessories: Custom hinges, connectors

Functional Accessories: Handles, guide rails, supports

Decorative Accessories: Custom signs, decorative strips

Product Qualification

Environmental Certifications:

RoHS Certification (Lead-free, Cadmium-free, and other hazardous substances-free)

REACH (EU Chemical Safety Standard)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production process quality control)

Testing Equipment: 3D scanner (0.8μm accuracy)

Deliver, Shipping, and Serving

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, providing comprehensive customized services based on customer needs. Standard Packaging: Copy paper + cardboard box

Custom Packaging: Blister tray/EPE foam + wooden crate

Global Export Experience: Familiar with international packaging and transportation standards, stable product supply to global markets such as Europe, America, Japan, and South Korea.

FAQ

Q1: What types of furniture accessories do you mainly process?

A: We mainly process various aluminum furniture accessories, including structural supports, connectors, guide rails, and custom handles. If you have specific accessory requirements, we can evaluate and quote based on your drawings.

Q2: What is the minimum order quantity?

A: We support small-batch trial orders; the specific quantity can be negotiated based on the complexity of the accessories. For long-term bulk orders, we can offer more competitive prices.

Q3: What is the processing precision you can achieve?

A: Our standard processing precision can be guaranteed to be ±0.1mm, which meets the assembly and usage requirements of most furniture accessories.

Q4: How does four-axis machining practically help furniture accessory production?

A: The main advantage of four-axis machining is its ability to machine multiple surfaces in a single setup, ensuring positional accuracy between different machined surfaces. This is particularly suitable for irregularly shaped parts requiring multi-angle machining.

Q5: Do you provide surface treatment services?

A: We can provide basic surface treatments such as sandblasting and anodizing. We can also assist in arranging professional surface treatment manufacturers for matching processing according to customer requirements.

Q6: How long does it take from quotation to production?

A: After receiving clear drawings, we usually provide a quotation within 1-2 business days. After order confirmation, the sample production cycle is approximately 5-7 days. The specific mass production time depends on the order quantity.

Welcome to provide drawings for consultation. We will provide specific processing solutions and quotations based on your needs.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), CNC lathes, milling machines, lathes, grinders, etc.; and over a dozen inspection equipment (inspection accuracy up to 0.001 MM), achieving internationally advanced machining capabilities. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts supporting industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with superior precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.