Large-Scale CNC Machining

As your product progresses from the prototype stage to mass production, you need a reliable and efficient manufacturing partner. We specialize in high-volume CNC machining. Through optimized production processes, automated equipment, and rigorous supply chain management, we achieve significant economies of scale, ensuring consistent quality and competitive pricing for every part.

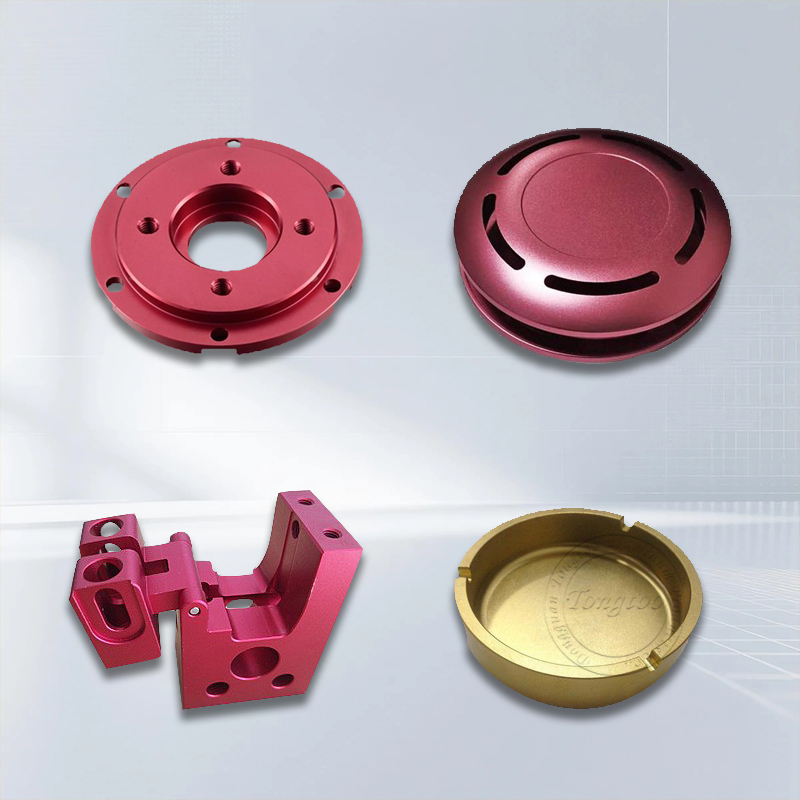

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. is a professional enterprise specializing in CNC precision machining, injection molding, mold development, and metal manufacturing of aluminum alloys. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have imported equipment from Germany, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. We focus on exquisite craftsmanship, rapid response, and comprehensive quality inspection to provide customized ODM/OEM solutions for global clients, striving to become a trusted strategic partner in the international industrial manufacturing field.

High-Volume CNC Machining Services - Cost-Effective Precision Parts Production Experts

Product Introduction

As your product progresses from the prototype stage to mass production, you need a reliable and efficient manufacturing partner. We specialize in high-volume CNC machining. Through optimized production processes, automated equipment, and rigorous supply chain management, we achieve significant economies of scale, ensuring consistent quality and competitive pricing for every part.

High-Volume CNC Machining Service Product Description:

High Precision and Consistency: Utilizing multi-axis CNC milling and turning centers, coupled with in-line inspection systems, we ensure that every part meets stringent tolerances (standards down to ±0.05mm) even in production volumes of tens of thousands.

Excellent Cost-Effectiveness: Process optimizations for high-volume production, such as multi-station fixtures, specialized tools, and optimized cutting parameters, significantly reduce unit costs.

Multi-Material Proficiency: We specialize in machining various aluminum alloys (such as 6061 and 7075), stainless steels (such as 304 and 316), titanium alloys, carbon steels, and engineering plastics to meet the application needs of diverse industries. Comprehensive Secondary Processing: We offer one-stop services, including anodizing, hard-oxidizing, electroplating, sandblasting, and powder coating, to meet the functional and aesthetic requirements of the final product.

Efficient Project Management: Professional project managers provide comprehensive support from design for manufacturing (DFM) to final delivery, ensuring smooth and on-time execution of large-scale orders.

Product Features and Applications

Extensive Mass Production Experience: We are a leading CNC precision machining manufacturer in China, serving numerous global OEM/ODM clients and deeply understanding the challenges and solutions of large-scale production.

Advanced Production Capabilities: Our production lines comprise over a hundred automated CNC machines (including three-, four-, and five-axis machining centers), enabling 24/7 continuous production and a monthly production capacity of millions of parts.

Strict Quality Control: Our factory is ISO 9001:2015 certified. Equipped with advanced testing equipment such as coordinate measuring machines (CMMs) and optical projectors, we ensure consistent quality control throughout the entire process, from incoming materials to manufacturing processes and finished products. Professional Engineering Support: Our team of engineers provides detailed Design, Function, and Function (DFM) reports before production, helping to optimize designs to improve production efficiency, reduce costs, and avoid potential defects. Stable Supply Chain and Delivery: We establish long-term partnerships with top-tier material suppliers to ensure a stable supply of raw materials. Through scientific production scheduling, we guarantee on-time delivery, even for large-volume orders.

Application Areas

Our high-volume CNC machined parts are widely used in various industries:

Automotive: sensor housings, connectors, transmission components, and new energy battery module parts.

Aerospace: drone frames, model aircraft accessories, interior trims, and test equipment parts.

Medical: instrument housings, surgical instrument handles, device brackets, and non-implantable medical parts.

Industrial Automation: robotic articulated arms, linear guides, pneumatic components, and customized fixtures.

Consumer Electronics: communication equipment housings, heat sinks, connectors, and smart home device components.

Our CNC Rapid Prototyping Service Process

Upload a file for an online quote: Simply provide a 3D CAD file (in formats such as STEP, IGES, and X_T) and your specific product requirements to receive a quote. Engineering Review and Confirmation: Our engineers conduct a Design for Manufacturing (DFM) analysis and confirm details with you. Production will be arranged after you confirm your order. Precision CNC Machining: High-precision CNC milling and turning are performed using advanced CNC equipment.

Post-Processing and Quality Inspection: Surface treatments such as deburring, sandblasting, anodizing, and painting are performed as required, followed by a final quality inspection.

Fast Shipping: After packaging, we ship globally via our partnered logistics partners. You can track your order status online.

Product Qualification

Environmental Certifications:

RoHS (lead-free, cadmium-free, and other hazardous substances)

REACH (EU Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (production quality control)

Inspection Equipment: Zeiss 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

As a professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive, customized services tailored to customer needs. Standard Packaging: Copy Paper + Carton

|

|

|

Custom Packaging: Blister Tray/EPE + Wooden Box

Global Export Experience: We are familiar with international packaging and shipping standards and consistently supply products to global markets including Europe, America, Japan, and South Korea.

FAQ

Q1: What is your definition of a "large-volume" order? What is the minimum order quantity (MOQ)?

A: We generally consider orders of 500 or more pieces as the starting point for large-volume production. However, for long-term projects, we can offer more flexible arrangements. The specific MOQ depends on the complexity of the part; please consult our sales team.

Q2: Compared to small orders, how much cost reduction can large-volume production bring?

A: The cost reduction varies depending on the part, but large-volume CNC machining typically reduces the cost per part by 15% to 40% by allocating initial setup costs, optimizing cutting parameters, and improving material utilization. We clearly reflect this advantage in our large-volume order quotes.

Q3: How do you ensure quality consistency in large-volume production?

A: We ensure quality through a comprehensive system:

First Article Inspection: Comprehensive measurements and reports are conducted before production.

In-Process Inspection: Critical dimensions are regularly inspected during production.

SPC (Statistical Process Control): Data monitoring of key processes to prevent deviations.

Final Inspection: Sampling inspections are conducted according to AQL standards before shipment.

Q4: Do you provide one-stop service from prototype to mass production?

A: Yes, this is our core strength. We can serve as your full-scale manufacturing partner, from rapid prototyping to small-batch pilot production to full-scale production, ensuring seamless adherence to technical requirements and quality standards.

Q5: What is the typical lead time for large-volume orders?

A: Lead time depends on the order quantity and complexity. Typically, the production lead time for the first batch is 4-6 weeks after the mold/tooling is ready. For ongoing volume orders, we can arrange rolling production to ensure a stable supply.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), CNC lathes, milling machines, lathes, grinders, etc.; and over a dozen inspection equipment (inspection accuracy up to 0.001 MM), achieving internationally advanced machining capabilities. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts supporting industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with superior precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.