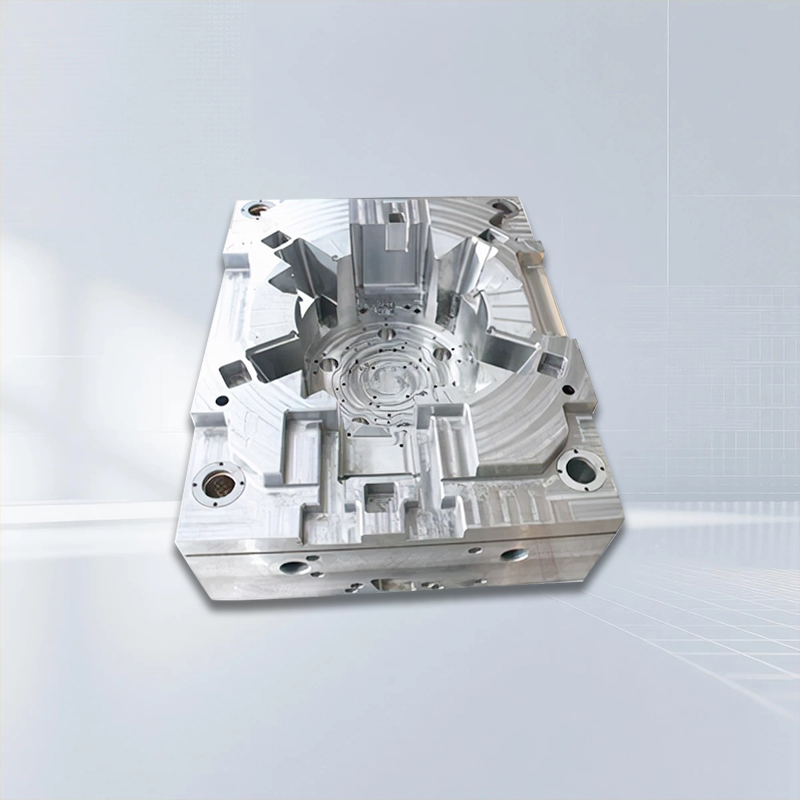

High-Speed Mirror Milling for Mold Cavities

Mold cavity CNC milling utilizes a computer numerically controlled milling machine with a high-speed rotating cutting tool to precisely remove material from the mold steel blank, thereby producing the three-dimensional shape of the mold cavity that meets the design requirements.

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. is a professional enterprise specializing in CNC precision machining, injection molding, mold development, and metal manufacturing of aluminum alloys. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have imported equipment from Germany, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. We focus on exquisite craftsmanship, rapid response, and comprehensive quality inspection to provide customized ODM/OEM solutions for global clients, striving to become a trusted strategic partner in the international industrial manufacturing field.

Product Introduction

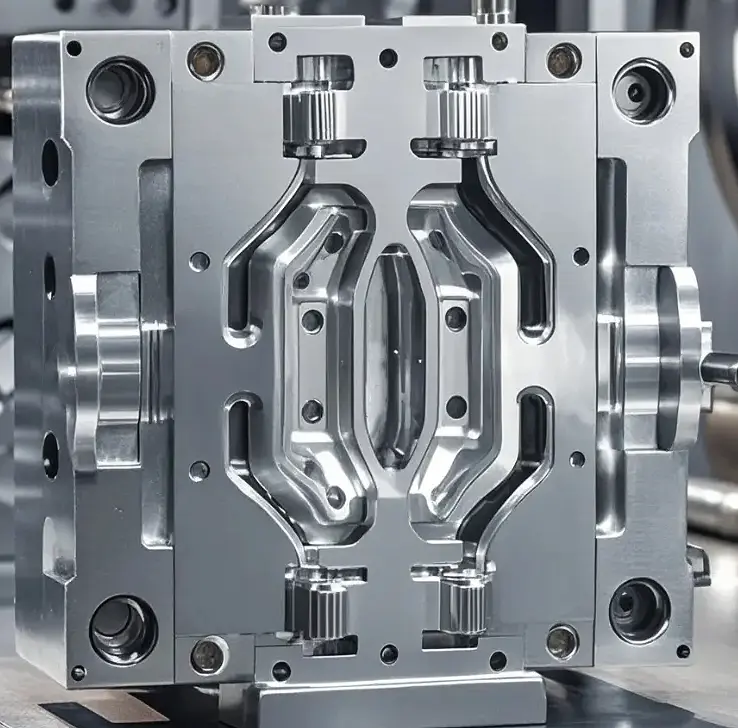

We provide full-process cavity and core milling solutions for injection molds, die-casting molds, and stamping molds, from roughing to finishing.

The mold cavity is the core component that gives a product its shape and surface quality. Its machining accuracy and efficiency directly determine the overall performance and lifespan of the mold. As a professional mold manufacturing supplier, we utilize advanced five-axis CNC machining centers and extensive process experience. We are committed to providing customers with high-precision and efficient mold cavity CNC milling services, covering the entire process from roughing to precision contouring. We are your reliable mold processing partner.

Product Introduction

Mold cavity CNC milling utilizes a computer numerically controlled milling machine with a high-speed rotating cutting tool to precisely remove material from the mold steel blank, thereby producing the three-dimensional shape of the mold cavity that meets the design requirements. It is an indispensable and critical process in modern mold manufacturing. Our services cover the machining of pre-hardened mold steels (such as P20 and 718H) and high-hardness mold steels (such as H13 and S136), offering comprehensive capabilities, from heavy-duty roughing of large cavities to precision finishing of complex and subtle features. Through optimized machining strategies and professional CAM programming, we ensure that the dimensional accuracy, geometric tolerances, and surface finish of the cavity meet or exceed your expectations, laying a perfect foundation for subsequent polishing, texturing, or EDM.

Product Features and Applications

High Precision and Geometric Fidelity

Precision Control: Utilizing high-performance CNC machining centers, we achieve tight dimensional tolerances (typically up to ±0.01mm) and excellent geometric reproducibility, ensuring that the cavity is perfectly aligned with the product design.

Complex Surface Processing: Utilizing 3+2-axis positioning and 5-axis simultaneous machining technologies, we efficiently and accurately machine complex 3D surfaces, such as deep cavities, steep walls, and undercuts (negative angles).

Strong Hard Steel Machining Capabilities

Efficient Roughing: Utilizing high-torque machine tools, we rapidly remove material, improving overall processing efficiency. Hard Milling Technology: Capable of directly finishing mold steels with a hardness of HRC 50 or higher after quenching (such as H13), reducing heat treatment distortion and streamlining the production process.

Excellent Surface Quality

Uniform Texture: Through sophisticated CAM programming, optimized tool paths and cutting parameters, we achieve a uniform, consistent surface texture, significantly reducing subsequent polishing efforts.

Predictable Results: Stable and controllable surface quality provides an ideal foundation for subsequent mirror polishing or specific levels of texturing (texturing).

Excellent Production Efficiency and Flexibility

Quick Changeover: Standardized fixtures and efficient workpiece clamping solutions reduce setup time.

Automation Options: Automated production lines can be used for extended periods of unattended processing, making it particularly suitable for the production of high-volume mold parts.

Rapid Prototyping: Rapidly respond to mold prototype and small-batch trial production needs, accelerating product development cycles.

Applications

Our mold cavity milling services are widely used in the manufacture of various molds:

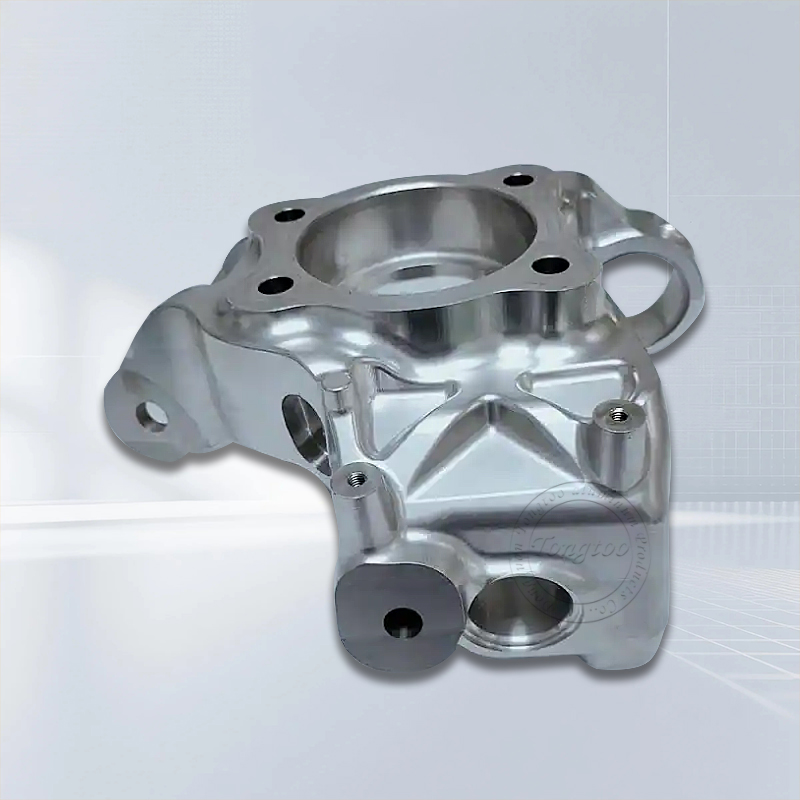

Injection Molds: Processing cavities and cores for various plastic products, such as automotive parts, appliance housings, and consumer goods. Die-casting Molds: Create mold cavities for die-cast parts made of aluminum alloys, zinc alloys, and other materials, such as automotive engine components and electronic equipment housings.

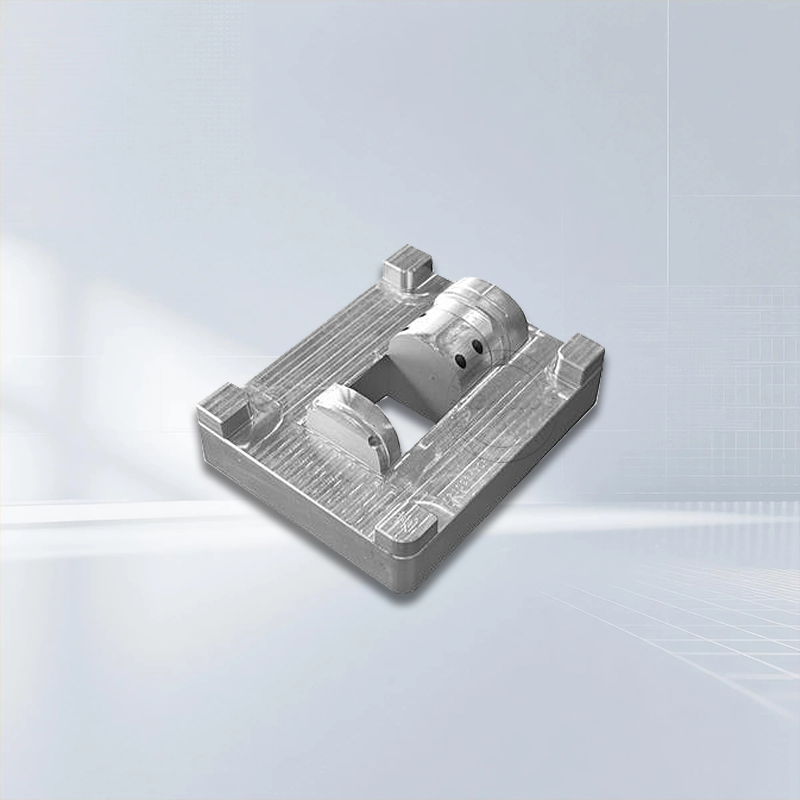

Stamping Molds: Process core components such as punches and dies for precision metal molds.

Blow Molds: Create mold cavities for hollow plastic products (such as bottles and containers).

Glass Molds: Create mold cavities for glassware.

Our Service Process

Upload File, Get an Online Quote: Simply provide a 3D CAD file (in formats such as STEP, IGES, X_T, etc.) and your product requirements to receive a quote.

Engineering Review and Confirmation: Our engineers conduct a Design for Manufacturing (DFM) analysis and confirm details with you. Once you confirm your order, production will be arranged. Precision CNC Machining: We utilize advanced CNC equipment for high-precision CNC milling and turning.

Post-Processing and Quality Inspection: Surface treatments such as deburring, sandblasting, anodizing, and painting are performed as required, followed by a final quality inspection.

Fast Shipping: After packaging, our products are shipped globally via our partner logistics partners. You can track your order status online.

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production Process Quality Control)

Testing Equipment: 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

We are a professional ODM & OEM manufacturer with over 20 years of precision machining experience. We provide comprehensive, customized services tailored to customer needs.

Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/PEF + wooden box

Global Export Experience: We are familiar with international packaging and shipping standards and consistently supply our products to global markets, including Europe, America, Japan, and South Korea.

FAQ

Q1: What type of CNC machine tools do you typically use for mold cavity machining?

A: We primarily use three-axis machining centers for routine machining, and we also have five-axis machining centers for precision cavities with complex curves, deep cavities, or those requiring multi-faceted machining in a single setup. Five-axis technology effectively improves accuracy and efficiency.

Q2: What are the typical tolerances for CNC milling mold cavities?

A: For the majority of mold cavity finishes, we can maintain a stable tolerance range of ±0.015 mm to ±0.025 mm. For specific features with more stringent requirements, we can perform targeted optimization to achieve even higher precision.

Q3: Are any additional steps required after CNC milling?

A: Yes, it depends on the final requirements. CNC milling provides the precise shape and base surface for the cavity. Manual or mechanical polishing is typically performed as needed to achieve a mirror finish or a specific finish, or electrical discharge machining (EDM) is performed to address sharp corners and narrow gaps that are difficult for CNC tools to reach.

Q4: What mold cavity sizes can you process?

A: Our processing capabilities cover molds ranging from small precision molds to large automotive mold cavities. Please provide the specific dimensions and weight of your mold, and we will confirm whether we can meet your needs.

Q5: How can I get a quote? What documents are required?

A: Please provide a 3D CAD model of the mold cavity (e.g., in STEP, IGS, or X_T formats) and a 2D engineering drawing (with critical dimensions, tolerances, material, and hardness requirements) showing the mold cavity. We will use this information to perform a design for manufacturability (DFM) analysis and provide you with a detailed quote.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), CNC lathes, milling machines, lathes, grinders, etc.; and over a dozen inspection equipment (inspection accuracy up to 0.001 MM), achieving internationally advanced machining capabilities. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts supporting industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with superior precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.