High-Precision Turning

Tongtoo Aluminum Products Co., Ltd. specializes in full-series precision turning of shafts, discs, and special-shaped rotating parts. Equipped with a dual-spindle + Y-axis powered turret milling system, it achieves IT5-level precision (roundness ≤ 0.002mm) and Ra0.1μm mirror finish. Targeting applications in hydraulic transmission, fluid control, and powertrain, we provide a one-stop solution from bar stock to finished product, addressing the challenges of efficient and precise machining of rotating parts.

Product Description

Product Introduction

Tongtoo Aluminum Products Co., Ltd. specializes in full-series precision turning of shafts, discs, and special-shaped rotating parts. Equipped with a dual-spindle + Y-axis powered turret milling system, it achieves IT5-level precision (roundness ≤ 0.002mm) and Ra0.1μm mirror finish. Targeting applications in hydraulic transmission, fluid control, and powertrain, we provide a one-stop solution from bar stock to finished product, addressing the challenges of efficient and precise machining of rotating parts.

Product Parameters

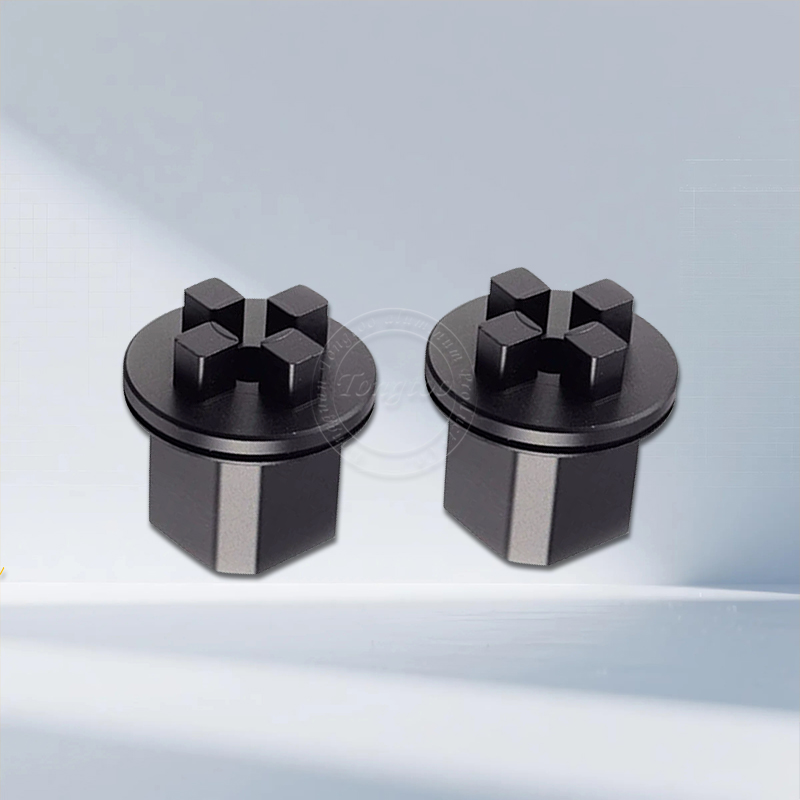

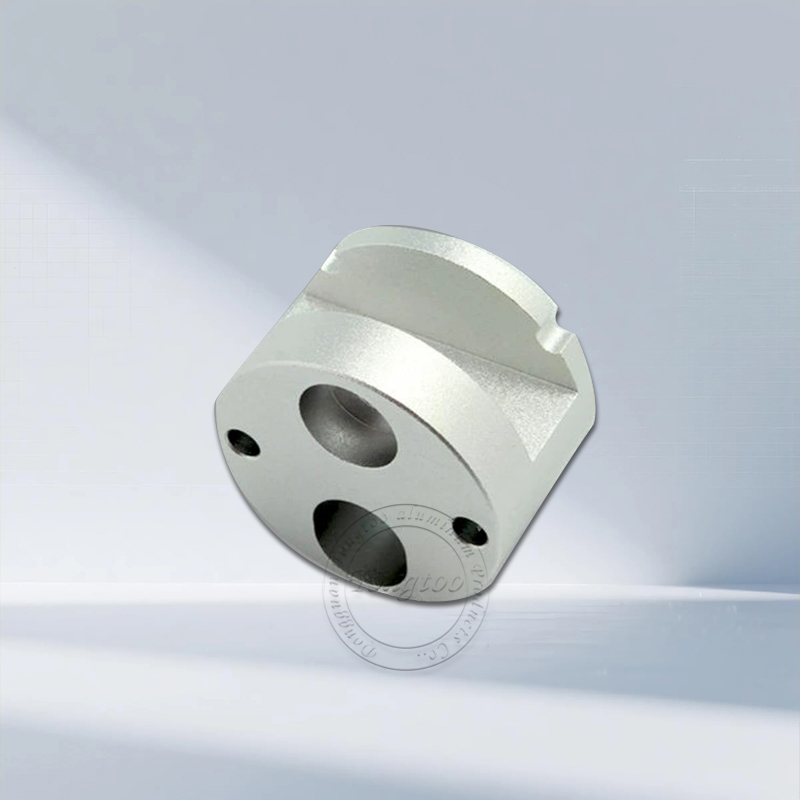

Product Name: CNC Precision Turning

Material: Aluminum Alloy/Titanium Alloy/Stainless Steel, etc.

Processing: CNC Turning/Milling/Turn-to-Mill

Surface Treatment: Anodizing/Hard Oxidation/Powder Coating/Laser Engraving

Product Features: Customizable holes, dimensions, and logos are supported.

Product Features and Applications

Core Advantages Comparison Table

Traditional Turning Pain Points: Our Solutions

Technical Specification Improvements

Secondary Clamping Errors: Dual-Spindle Synchronous Material Receiving: 300% Increase in Coaxiality

Limitations for Special-Shaped Grooving: C-Axis + Y-Axis Simultaneous Milling: Complex Features Formed in One Step

Slender Shaft Chatter: Tool Rest + Active Vibration Control System: 1:50 Aspect Ratio, Roundness ≤ 0.005mm

Small-Batch Changeover Time: Hydraulic Quick-Change Chuck (≤ 90 Seconds)

Equipment Utilization Increased by 40%

Application Scenarios

Industry: Typical Components: Technical Highlights

Hydraulic Systems: Servo Valve Spools/Plunger Pump Cylinders: 0.1μm Step Shaft Turning

New Energy Vehicles: Motor Shafts/Reducer Input Flanges Spline and bearing seat simultaneous machining

Semiconductor equipment, vacuum chamber flanges/gas nozzles, 316L non-magnetic machining

Medical devices, artificial joint stems/minimally invasive surgical cannulas, medical titanium alloy mirror turning

Fluid control, metering valve tapers/bellows fittings, NIST standard taper fit

Product Details

Cluster of cutting-edge equipment

Swiss-type sliding head lathe: Precision shafts Ø3-32mm

Twin-turret horizontal lathe: Machining large parts Ø600mm x 1500mm

Mill-turn center: 11-axis, 5-axis simultaneous operation (B-axis swing angle ±110°)

Breakthrough technology

A revolution in hard turning

Ra 0.4μm finish turning of hardened steel (HRC62) (alternative to grinding)

Cubic boron nitride (CBN) insert life increased by 8 times

Product Qualification

Environmental certifications:

RoHS certification (lead-free, cadmium-free, and other hazardous substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production Process Quality Control)

Inspection Equipment: Zeiss 3D Scanner (0.8μm Accuracy)

Delivery, Shipping, and Serving

|

|

|

A professional ODM & OEM manufacturer with over 20 years of precision machining experience. We prioritize customer needs and provide comprehensive customized services.

Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/PEF + wooden box

FAQ

Q1: How to ensure straightness when turning deep holes (L/D > 30)?

High-pressure internal coolant drill rod (7MPa flushing and chip removal) + laser-guided tool setting

Q2: How to control costs with small batches and high-variety products?

Tiered Pricing Model:

1-50 pieces: Quick-change tooling package

50-500 pieces: Dedicated fixture sharing

500+ pieces: Automated production line

Q3: How to avoid work hardening when turning stainless steel?

Golden Parameter Combination:

① VC = 180 m/min

② f = 0.08 mm/r

③ Coated insert (AlTiN) (with high-pressure emulsion cooling)

Q4: How to efficiently clamp eccentric parts?

Four-jaw power chuck + 3D-printed conformable bushing (repeatability ≤ 0.003 mm)

Q5: How to achieve mirror turning (Ra ≤ 0.1 μm)?

Three-stage process control:

① Diamond tool (R 0.2 mm)

② Constant temperature workshop (20°C ± 1°C)

③ Active vibration isolation foundation