High-Precision CNC Milling Service

We provide professional high-precision CNC milling services, dedicated to manufacturing complex and precision parts and components for global customers.

Product Description

High-Precision CNC Milling Services Multi-Material Precision Machining Solutions from Prototype to Mass Production

Dongguan Tongtoo Aluminum Products Co., Ltd. is a professional enterprise specializing in CNC precision machining of aluminum alloys, injection molding, mold development, and metal manufacturing. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have introduced imported equipment from Germany, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. We focus on exquisite craftsmanship, rapid response, and comprehensive quality inspection to provide customized ODM/OEM solutions for global customers, striving to become a trusted strategic partner in the international industrial manufacturing field.

Product Introduction

We provide professional high-precision CNC milling services, dedicated to manufacturing complex and precision parts and components for global customers. Utilizing advanced multi-axis CNC milling machines, a strict quality control system, and extensive experience in material processing, we can handle a variety of materials, including aluminum alloys, stainless steel, titanium alloys, and engineering plastics, meeting all needs from rapid prototyping to mass production. No matter what harsh environment your parts are intended for, we can provide machining solutions that meet stringent tolerances and excellent surface finish requirements.

Product Features

Micron-Level Machining:Utilizing a multi-axis CNC milling center and high-performance cutting system, it achieves a tight tolerance of ±0.005 mm, ensuring perfect fit of parts in precision assembly.

Extensive Material Machining Capabilities:Extensive experience in handling various materials: aluminum alloys (lightweight), stainless steel (corrosion resistant), titanium alloys (high strength-to-weight ratio), brass, and engineering plastics such as POM and nylon, meeting the physical and chemical performance requirements of different applications.

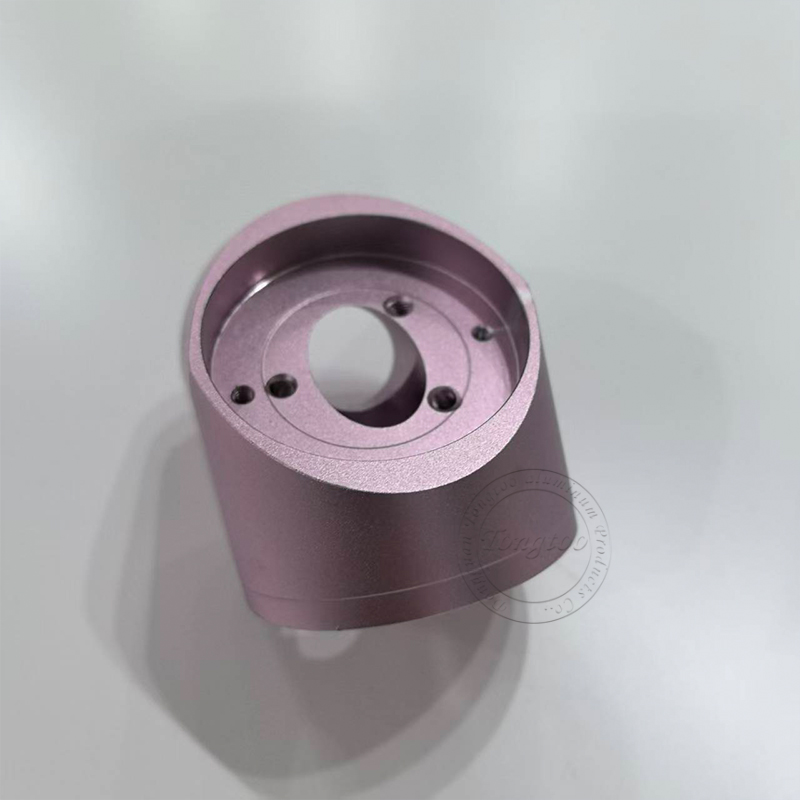

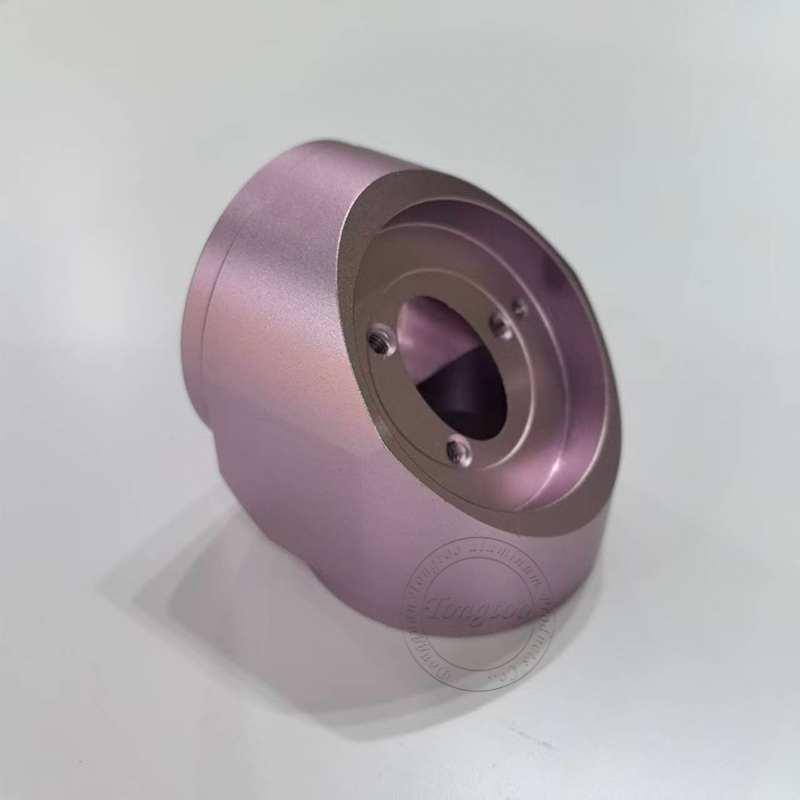

Complex Geometry Machining:Proficient in manufacturing parts with deep cavities, thin walls, micro-holes, and complex curved surfaces. 5-axis machining enables multi-face machining in a single setup, reducing error accumulation.

Integrated Surface Treatment:Offers a variety of surface treatment options, including anodizing, passivation, heat treatment, electroplating, and sandblasting, improving wear and corrosion resistance and meeting special appearance requirements.

End-to-End Quality Assurance:Adhering to the ISO 9001 quality system, equipped with coordinate measuring machines, contour projectors, and other inspection equipment, it implements end-to-end quality monitoring from the first article to batch products, providing complete inspection reports.

Application Areas

Aerospace: Engine components, UAV structural components, navigation system housings, satellite brackets

Medical Equipment: Surgical instruments, diagnostic equipment housings, implant prototypes, medical robot joints

Automotive Manufacturing: Sensor housings, fuel system parts, transmission test components, new energy vehicle battery boxes

Industrial Automation: Robotic arm end effectors, linear guides, precision clamps, conveyor system components

Electronics & Communications: RF device housings, heat sinks, waveguide structures, insulating supports

Product Qualifications

Environmental Certifications:

RoHS Certification (Lead-free, Cadmium-free, and other hazardous substances-free)

REACH (EU Chemical Safety Standard)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production process quality control)

Testing Equipment: 3D scanner (0.8μm accuracy)

Deliver, Shipping, and Serving

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, providing comprehensive customized services based on customer needs.

Standard Packaging: Copy paper + cardboard box

Custom Packaging: Blister tray/EPE foam + wooden crate

Global Export Experience: Familiar with international packaging and transportation standards, stable product supply to global markets such as Europe, America, Japan, and South Korea.

FAQ

Q1: What is the typical tolerance range you can handle?

We can achieve tolerances from ±0.005 mm to ±0.025 mm according to your design requirements. For more stringent requirements, we will strive to meet them through process optimization and specialized equipment.

Q2: Besides aluminum, what other materials do you recommend for high-strength applications?

For applications requiring high strength, corrosion resistance, and high temperature resistance, we recommend stainless steel (such as 304, 316), titanium alloys (TC4), and pre-hardened die steel. These materials are highly favored in the aerospace and medical fields.

Q3: How do I request a quote for my project?

Please provide a 3D CAD model (STEP/IGS format) and 2D engineering drawings (PDF/DWG), specifying materials, tolerances, surface treatments, and target quantities in the drawings. We will provide a detailed quote within 24 hours based on this information.

Q4: Do you support small-batch prototyping? Can you deliver quickly?

We strongly support small-batch rapid prototyping. After receiving your complete data, we can complete processing and ship within 5-7 business days, helping you quickly complete design verification.

Q5: Do you provide global shipping services?

Yes, we have established long-term partnerships with international logistics companies such as DHL and FedEx, providing safe and convenient door-to-door shipping services to global customers and assisting with customs clearance documents.

Welcome to provide drawings for consultation; we will provide specific processing solutions and quotes based on your needs.

Company Introduction: Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), CNC lathes, milling machines, lathes, grinding machines, etc.; and more than a dozen inspection equipment (inspection accuracy up to 0.001 MM), with machining capabilities reaching international advanced levels. The Tengtu team possesses top-tier expertise in mold design and CNC machining. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team utilizes CNC machining to manufacture high-performance parts supporting industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with exceptional precision, tight tolerances, and premium materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.