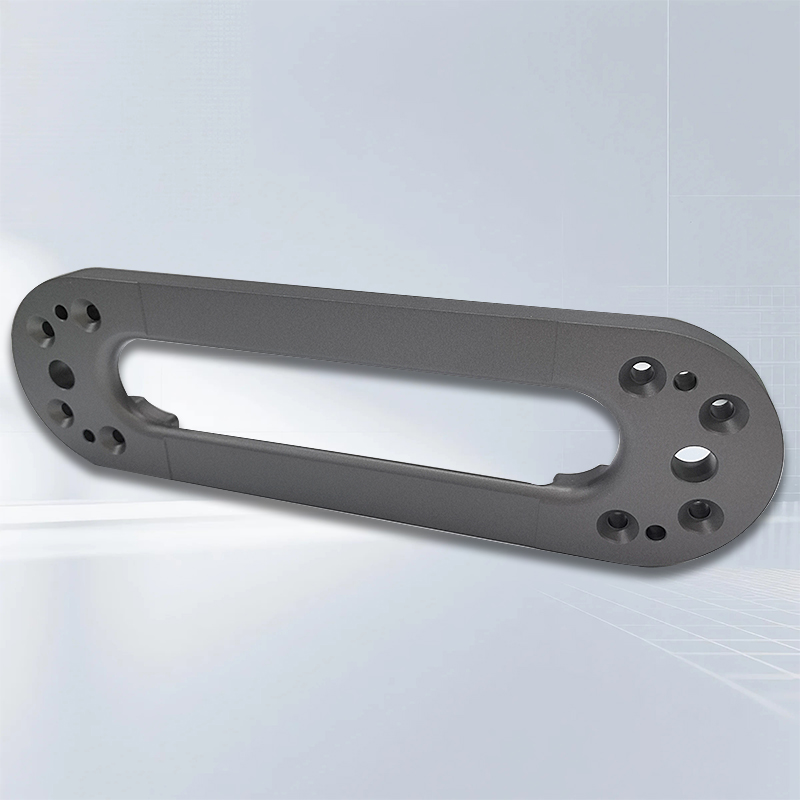

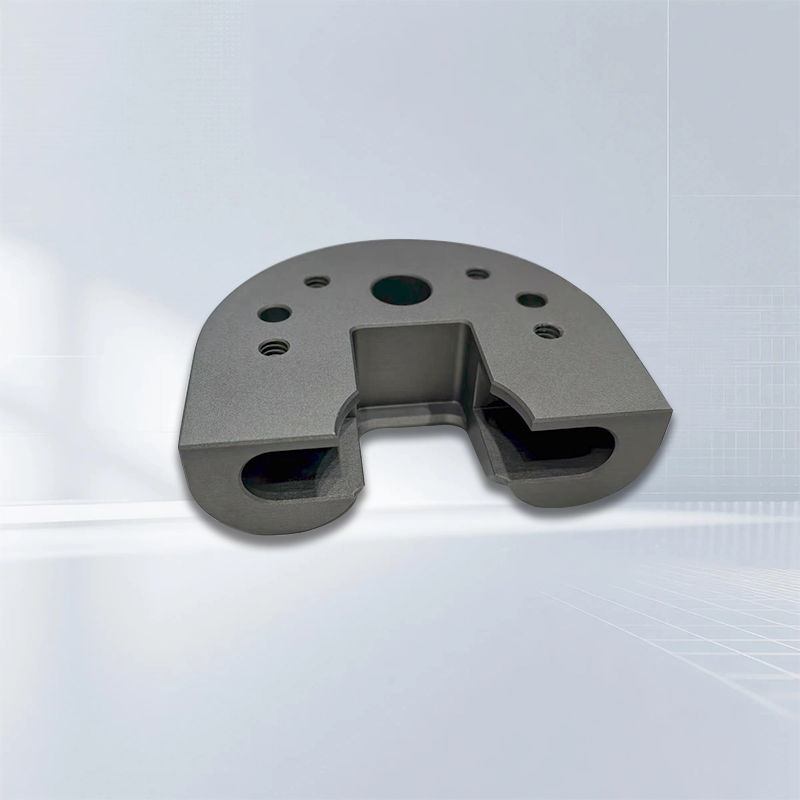

High-Precision Aluminum CNC Milling Service for Aerospace Components

We specialize in providing the highest standards of precision metal component manufacturing and solutions for the aerospace industry. Leveraging advanced multi-axis CNC machining centers (3-, 4-, and 5-axis) and our own in-house surface treatment (anodizing) facility, we offer integrated precision manufacturing from raw material to finished product.

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. specializes in aluminum alloy CNC precision machining, injection molding, mold development, and metal manufacturing. We are ISO 9001 certified and strictly implement the 6S management system. Using equipment imported from Germany, our products are exported to over 20 countries, including Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million units. With exquisite craftsmanship, rapid response, and end-to-end quality inspection at our core, we provide customized ODM/OEM solutions to our global customers, striving to become a trusted strategic partner in the international industrial manufacturing sector.

Product Introduction

We specialize in providing the highest standards of precision metal component manufacturing and solutions for the aerospace industry. Leveraging advanced multi-axis CNC machining centers (3-, 4-, and 5-axis) and our own in-house surface treatment (anodizing) facility, we offer integrated precision manufacturing from raw material to finished product. Strictly adhering to the ASO9001 quality management system, every component we produce meets the aerospace industry's stringent requirements for extreme precision, superior performance, and unconditional reliability, making us your trusted partner for critical components.

Core Advantages and Features

Ultra-high precision and complex geometry machining capabilities

5-axis simultaneous machining: Efficiently complete the precision machining of complex curved surfaces, cavities, inclined holes, and special-shaped structures (such as impellers, engine casings, and brackets) in a single operation, reducing setup times and ensuring extremely high geometric tolerances and dimensional consistency.

Multi-technology combination: Combining 3-, 4-, and 5-axis CNC equipment, we can select the optimal machining strategy for parts of varying complexity, balancing efficiency and precision. Expertise in aerospace-grade materials. Proficient in the processing characteristics of a wide range of specialized aerospace materials, including but not limited to:

Aluminum alloys (e.g., 7075, 2024, 6061): High strength-to-weight ratio, used in structural parts, brackets, and housings.

Titanium alloys (e.g., Ti-6Al-4V): Excellent corrosion resistance and high- and low-temperature performance, used in critical engine components and landing gear.

High-temperature alloys (e.g., Inconel, Hastelloy): Excellent heat and corrosion resistance, used in engine hot-end components.

Stainless steels (e.g., 15-5PH, 17-4PH): High strength and corrosion resistance, used in various fasteners and load-bearing components.

Application Areas

Our precision components are widely used in various key systems of aircraft:

Flight Control Systems: servo housings, sensor brackets, connecting rods, servo valve blocks

Engine Systems: compressor blade mounts, fuel nozzle housings, engine mounting brackets, thermal management components

Airframe Structures: bulkhead brackets, connectors, hinges, door assemblies, UAV fuselage frames

Landing Gear Systems: actuator components, small load-bearing structural components

Avionics: radar housings/brackets, electronic equipment cooling plates, avionics mounting brackets

Interior and Seating Systems: metal structural components that meet aviation flame retardant requirements

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (production process quality control)

Inspection Equipment: Zeiss 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

We are a professional ODM & OEM manufacturer with over 20 years of precision machining experience. We prioritize customer needs and provide comprehensive customized services.

Delivery, Shipping, and Serving

|

|

|

Standard Packaging: Copy paper + cardboard

Custom Packaging: Blister tray/PE foam + wooden box

FAQ

Q1: What are the advantages of 5-axis machining over 3- or 4-axis machining?

A: The main advantages of 5-axis machining are: 1) Complex machining can be completed in a single setup, eliminating the cumulative errors caused by multiple setups and achieving higher precision. 2) It can process complex curved surfaces and undercuts that 3-axis equipment cannot reach. 3) It allows the use of shorter tools, improving machining efficiency and quality. This is crucial for complex parts in the aerospace industry.

Q2: What does having our own oxidation plant mean for our customers?

A: It means:

1) Absolute delivery control: No outsourcing is required, eliminating supply chain uncertainties and significantly shortening the overall production cycle. 2) Strict Quality Control: From CNC machining to anodizing, the entire process is completed in-house, eliminating potential contamination or damage from transportation and external handling, ensuring seamless integration of surface treatment quality and part processing quality.

3) Enhanced Confidentiality: Critical aerospace components never leave the factory, ensuring greater information security.

Q4: What information do you need for a machining quote?

A: To provide an accurate and fast quote, please provide the following:

Detailed product drawings (PDF/STEP/IGS format): including all dimensions, tolerances, technical requirements, and material specifications.

Annual or single-item quantity required.

Treatment requirements (e.g., anodizing type, color, thickness, etc.).

Any special certifications or testing requirements (e.g., NADCAP, mechanical properties testing, etc.).

Company Introduction

Our 5,000 square meter workshop is equipped with hundreds of CNC machining centers (with machining accuracy up to 0.002 mm), CNC turning and milling machines, CNC lathes, milling machines, lathes, grinders, and more; as well as over a dozen inspection equipment (with inspection accuracy up to 0.001 mm). Our machining capabilities reach internationally advanced levels. The Tengtu team possesses the most professional expertise in mold design and CNC machining. We will work closely with you throughout prototyping, production, assembly, inspection, packaging, and final delivery to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts for industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with exceptional precision, tight tolerances, and premium materials. Over the past 11 years, Tengtu has established a strong reputation for efficiency, quality, reliability, and on-time delivery.