Custom CNC Machined Precision Parts for Electronic Devices

Our CNC electronic precision parts services are tailored specifically for the electronics industry, specializing in the machining of micro and ultra-precision components requiring extremely high dimensional stability, superior electromagnetic shielding, and exceptional heat dissipation. We deeply understand the electronics industry's demanding requirements for precision and reliability, and are dedicated to providing critical internal components for the communications, consumer electronics, semiconductor, and other industries.

Product Description

Product Introduction

Our CNC electronic precision parts services are tailored specifically for the electronics industry, specializing in the machining of micro and ultra-precision components requiring extremely high dimensional stability, superior electromagnetic shielding, and exceptional heat dissipation. We deeply understand the electronics industry's demanding requirements for precision and reliability, and are dedicated to providing critical internal components for the communications, consumer electronics, semiconductor, and other industries.

Product Parameters

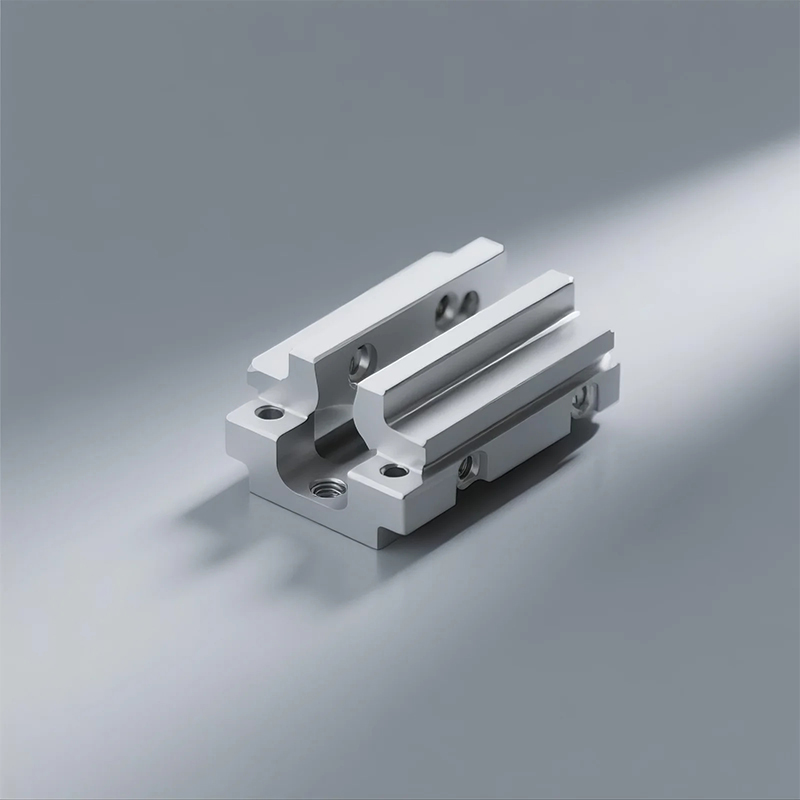

Product Name: CNC Electronic Precision Parts

Material: Aluminum alloy, stainless steel, titanium alloy, copper, die steel, PEEK, etc.

Processing: CNC machining/milling/stamping/die-casting

Surface Treatment: Anodizing/hard anodizing/powder coating/laser engraving

Product Features: Customizable holes, dimensions, and logos are supported.

Product Features and Applications

Core Features and Advantages:

Microscopic Precision: We specialize in miniaturized component machining, excelling at processing thin-walled components, micropores, and fine threads with extremely tight tolerances (often reaching ±0.005mm or higher), meeting the tight internal space requirements of electronic products. EMI/RFI Shielding Design: We are proficient in precision machining metal shielding cavities, covers, and springs, effectively isolating electromagnetic interference and ensuring device signal integrity.

Thermal Management Solutions: We can process complex heat sinks, vapor chamber bases, and other high-performance heat sinks. Using highly thermally conductive materials (such as 6061 aluminum alloy and copper), we significantly improve device heat dissipation efficiency.

Pollution-Free Clean Production: We implement dedicated cleaning processes to ensure that parts are free of oil and metal shavings after processing, preventing contamination of sensitive electronic components.

Applications:

Communications Equipment: 5G base station filters, antenna elements, RF connectors, waveguide cavities, and optical module housings.

Electronics: Smartphone midframes, camera rings, smartwatch components, headphone charging case hinges, and internal brackets.

Semiconductor Manufacturing: Wafer probe cards, fixtures, vacuum chucks, and sensor housings.

Computer Hardware: Server heat sinks, hard drive components, connectors, and graphics card brackets. Automotive Electronics: ECU (Electronic Control Unit) housings, radar sensor brackets, and in-vehicle entertainment system components.

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production Process Quality Control)

Testing Equipment: Zeiss 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

|

|

|

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive, customized services tailored to customer needs.

Standard Packaging: Copy paper + carton

Customized Packaging: Blister tray/PEF + wooden box

FAQ

Q: How can I prevent surface scratches and deformation when machining precision electronic parts?

A: We use specialized custom tooling and non-contact fixtures for scratch-prone materials (such as anodized aluminum). For thin-walled parts prone to deformation, special clamping strategies and machining path programming are employed to minimize stress.

Q: Can you machine complete cavities with electromagnetic shielding (EMI) functionality?

A: Yes. We frequently machine shielding cavities for customers with conductive spring grooves, shielding lips, and conductive aperture arrays, ensuring that they form an effective Faraday cage when combined with other components.

Q: How do you ensure part cleanliness meets electronics-grade requirements?

A: We have a rigorous cleaning process, including multiple ultrasonic cleaning passes, anhydrous ethanol wiping, high-pressure air blasting, and vacuum packaging, ensuring that delivered parts are dust-free and ready for assembly.

Q: For parts requiring high heat dissipation, what materials and processes are recommended?

A: We recommend using 1060/6063 aluminum alloy or C11000 copper, both of which have high thermal conductivity. We use precision milling to create densely packed heat sink fins, which can be further fabricated through post-processing.