CNC Turning Machining

Ultra-High Precision: Utilizing imported CNC machining centers, we achieve tolerances of ±0.01mm, meeting aerospace-grade standards. Multi-material compatibility: excels at drilling holes in aluminum alloys, stainless steel, titanium alloys, copper, engineering plastics, and other materials, solving the problem of tool breakage in hard materials.

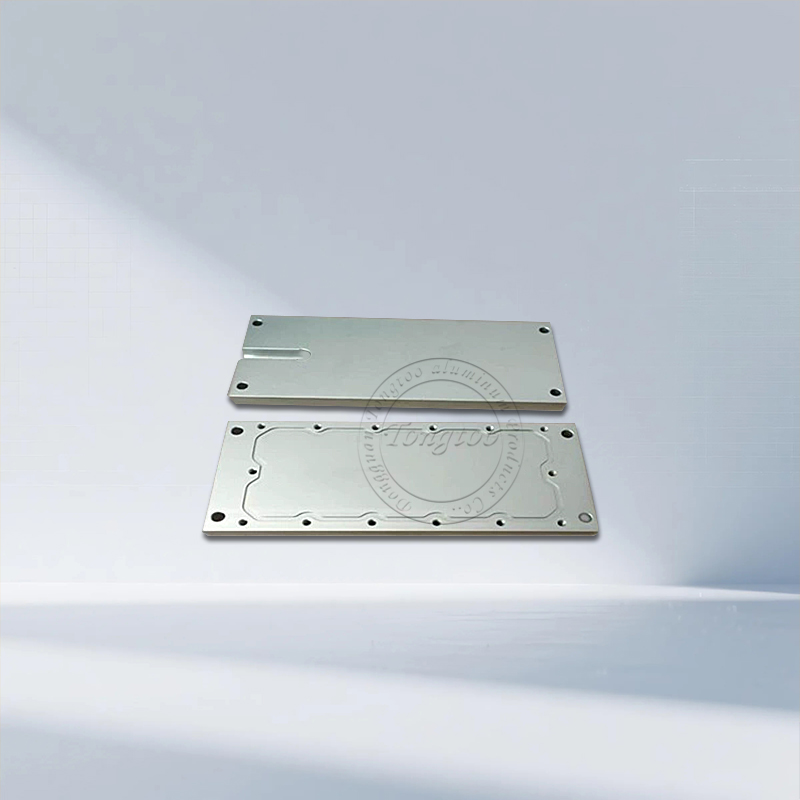

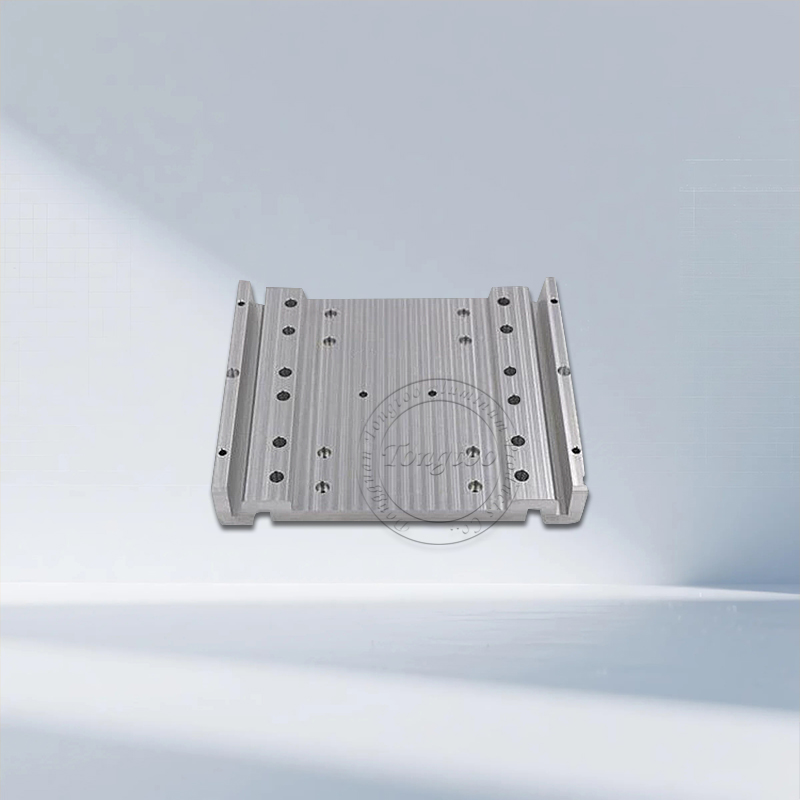

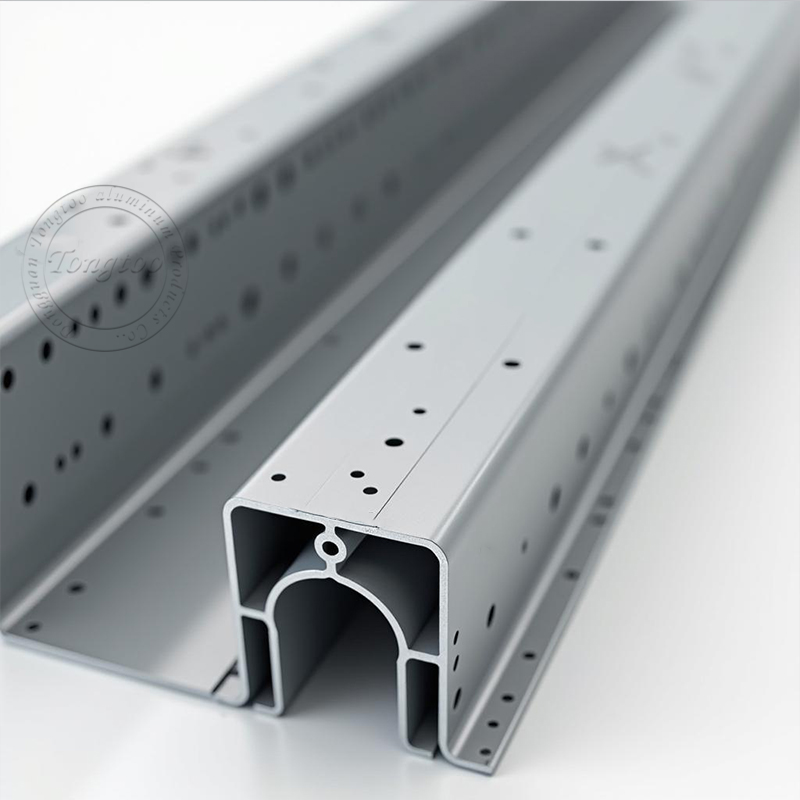

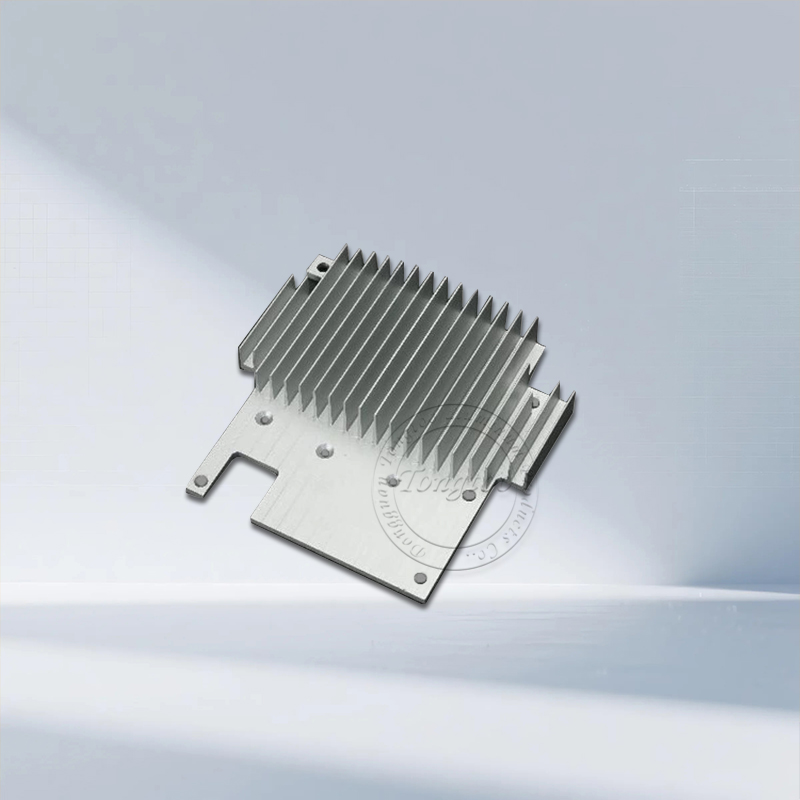

Product Description

Product Introduction

Tongtoo Aluminum Products Co., Ltd. specializes in full-series precision turning of shafts, discs, and special-shaped rotating parts. Equipped with a dual-spindle + Y-axis powered turret milling system, we achieve IT5-level precision (roundness ≤ 0.002mm) and Ra 0.1μm mirror finish. We offer a one-stop solution from bar stock to finished product for applications such as hydraulic transmission, fluid control, and powertrain, addressing the challenges of efficient and precise machining of rotating parts.

Product Parameters

Product Name: High-Precision CNC Drilling

Material: Aluminum Alloy/Titanium Alloy/Stainless Steel

Processing: CNC Turning/Milling

Surface Treatment: Anodizing/Hard Oxidation/Powder Coating/Laser Engraving

Product Features: Customizable hole openings, dimensions, and logos are supported.

Product Features and Applications

Ultra-High Precision: Utilizing imported CNC machining centers, we achieve tolerances of ±0.01mm, meeting aerospace-grade standards. Multi-material compatibility: excels at drilling holes in aluminum alloys, stainless steel, titanium alloys, copper, engineering plastics, and other materials, solving the problem of tool breakage in hard materials.

Complex hole customization: supports deep hole drilling (aspect ratio of 15:1), stepped holes, beveled holes, special-shaped holes, and integrated tapping.

Flexible mass production: From single-piece prototyping to mass production of tens of thousands of pieces, supporting just-in-time delivery and shortening supply chain cycles. Applications

Automotive Parts: Engine block oil channel holes, new energy battery module positioning holes

Electronic Communications: 5G base station radiator cluster holes, semiconductor fixture precision guide holes

Medical Devices: Micro-hole machining for surgical instruments, multi-directional fluid holes for implants

Mold Manufacturing: Cooling holes for injection molds, ejector hole arrays for die-casting molds

Product Details

Machining Hole Diameter: 0.5mm to 80mm

Maximum Hole Depth: 300mm (with deep hole drilling module)

Positioning Accuracy: ±0.005mm

Surface Roughness: Ra 0.8μm

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (production process quality control)

Inspection Equipment: Zeiss 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

|

|

|

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive customized services tailored to customer needs.

Standard Packaging: Copy paper + cardboard

Custom Packaging: Blister tray/PEF + wooden box

FAQ

Q1: Can your company handle micro-hole machining in thin stainless steel sheets (0.5mm)? How do you ensure zero deformation?

Solution: Using ultra-fine carbide drills (minimum 0.3mm) with vacuum fixtures to suppress vibration. High-speed, low-feed technology (20,000rpm + 0.003mm/rev) allows for controllable deformation within ±0.02mm.

Q2: How do you ensure hole wall roughness and straightness during deep hole machining?

Key Technologies: Gun drilling + high-pressure internal coolant system (7MPa coolant pressure). Chip compensation every 50mm depth. Real-time tool wear monitoring and automatic offset compensation. Achieves Ra 1.6μm and straightness ≤ 0.03/100mm.

Q3: Does the processing of special materials support small-volume orders?

Service Commitment: We offer high-temperature alloy coated drills (TiAlN coating).

Customized variable parameter drilling strategies: Segmented speed/feed control.

Material Inventory Support: Customized special materials are supported.

Q4: How can we improve efficiency in group hole machining?

Efficiency Enhancement Solutions: Multi-Axis Machining Center:

Automatic Tool Changer (ATC)

Combined Drilling and Milling Program: Automatic Hole Position Recognition + Pecking Cycle