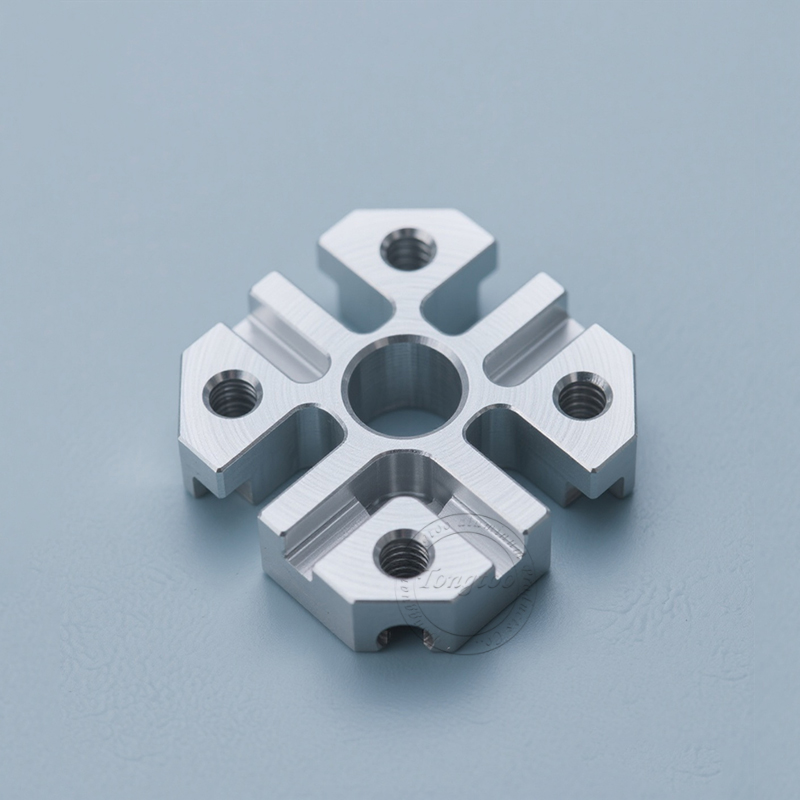

CNC Prototyping Rapid CNC Prototyping

Our CNC rapid prototyping service utilizes advanced CNC machine tools and specialized technology to transform your 3D CAD model into a high-precision physical part within days, helping you efficiently complete design verification, functional testing, and market demonstrations.

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. is a professional enterprise specializing in CNC precision machining, injection molding, mold development, and metal manufacturing of aluminum alloys. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have imported equipment from Germany, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. We focus on exquisite craftsmanship, rapid response, and comprehensive quality inspection to provide customized ODM/OEM solutions for global clients, striving to become a trusted strategic partner in the international industrial manufacturing field.

Product Introduction

Our CNC rapid prototyping service utilizes advanced CNC machine tools and specialized technology to transform your 3D CAD model into a high-precision physical part within days, helping you efficiently complete design verification, functional testing, and market demonstrations.

CNC Rapid Prototyping Service Product Description:

High-precision machining - Tight tolerance control of ±0.01mm ensures your prototype perfectly matches your design.

Fast Delivery - Rapid prototyping with standard delivery times as low as 3-5 days, and expedited delivery available for urgent orders.

Various Materials - Over 50 metal prototypes (such as aluminum, steel, and copper) and plastic prototypes (such as ABS, PC, and nylon) available.

Competitive Pricing - Get instant quotes online with transparent pricing and no hidden fees.

Product Features and Applications

Our Technical Advantages and Process Features

Extensive Material and Process Capabilities

We maintain a comprehensive material library to meet the prototyping needs of diverse industries. Whether you require high-strength, lightweight aluminum alloy prototypes, corrosion-resistant stainless steel machining, or engineered plastic prototypes for insulation testing, we can handle them. We support 3-axis, 4-axis, and 5-axis CNC machining, enabling the processing of complex geometries and deep cavities.

Built for Low-Volume Production: In addition to rapid single-part prototyping, we're also your ideal partner for low-volume production. Going directly from CAD files to finished products eliminates the need for molds, seamlessly bridging the entire process from prototype to pilot production, saving time and tooling costs.

Professional Technical Support and Quality Assurance: Our team of engineers will carefully review your design files and provide design-for-manufacturing (DFM) recommendations to optimize your design to reduce costs and shorten lead times. Every prototype undergoes rigorous quality inspection to ensure the highest quality delivered to you.

Applications

Our CNC prototyping services are widely used in:

Automotive component prototypes

Aerospace precision components

Medical device housings and parts

Consumer electronics structural and functional components

Robotics and automation components

Industrial equipment fixtures and jigs

Service Process

Upload a file for an online quote: Simply provide a 3D CAD file (in formats such as STEP, IGES, and X_T) and your product requirements to receive a quote. Engineering Review and Confirmation: Our engineers conduct a Design for Manufacturing (DFM) analysis and confirm details with you. Production will be arranged after you confirm your order. Precision CNC Machining: High-precision CNC milling and turning are performed using advanced CNC equipment.

Post-Processing and Quality Inspection: Surface treatments such as deburring, sandblasting, anodizing, and painting are performed as required, followed by a final quality inspection.

Fast Shipping: After packaging, we ship globally via our partnered logistics partners. You can track your order status online.

Product Qualification

Environmental Certifications:

RoHS (lead-free, cadmium-free, and other hazardous substances)

REACH (EU Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (production quality control)

Inspection Equipment: Zeiss 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

As a professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive, customized services tailored to customer needs. Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/PE foam + wooden box

Global Export Experience: Familiar with international packaging and shipping standards, we consistently supply products to global markets including Europe, America, Japan, and South Korea.

FAQ

Q1: What is CNC rapid prototyping? What stages is it suitable for?

A: CNC rapid prototyping refers to the process of using computer numerical control (CNC) machining technology to quickly and accurately produce functional prototypes or small batches of parts. It is primarily used for:

Design Verification: Verifying the product's appearance, assembly, and structural rationality.

Functional Testing: Testing the performance, durability, and reliability of parts under actual operating conditions.

Market Demonstration: Providing high-quality mockups for trade shows, customer evaluations, or crowdfunding.

Small-batch Trial Production: Conducting small-scale production to verify market response before starting production.

Q2: What surface finish options do you offer?

A: We offer a wide range of post-production surface treatments to meet diverse aesthetic and functional requirements:

Metal Prototyping: Anodizing (various colors), sandblasting, passivation, electroplating, powder coating, etc.

Plastic prototypes: painting, silk-screen printing, grinding and polishing, UV coating, and more.

Our engineers can recommend the most suitable solution based on your needs.

Q3: Is there a minimum order quantity (MOQ)?

A: No. We specialize in rapid prototyping and small-batch production, with a minimum order of one piece. This allows you to validate your design at the lowest cost and iterate flexibly.

Q4: What is your machining accuracy?

A: Our standard machining tolerance is typically ±0.1mm. For demanding features, we can achieve ±0.025mm or even higher accuracy with our advanced equipment and processes. Please let us know your specific tolerance requirements when inquiring.

Q5: What if the actual part differs from my design?

A: Before production, our engineers will perform a manufacturability analysis and communicate with you about any potential issues. We promise that the parts we deliver will strictly conform to the agreed drawings and specifications. Every batch undergoes rigorous quality inspection before shipment to ensure quality.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), CNC lathes, milling machines, lathes, grinders, etc.; and over a dozen inspection equipment (inspection accuracy up to 0.001 MM), achieving internationally advanced machining capabilities. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts supporting industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with superior precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.