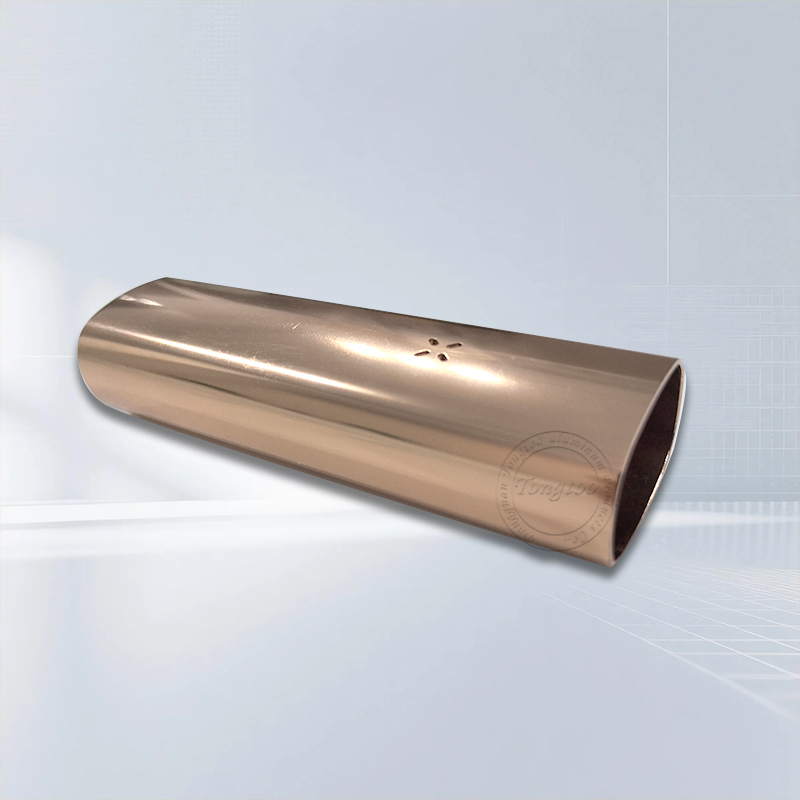

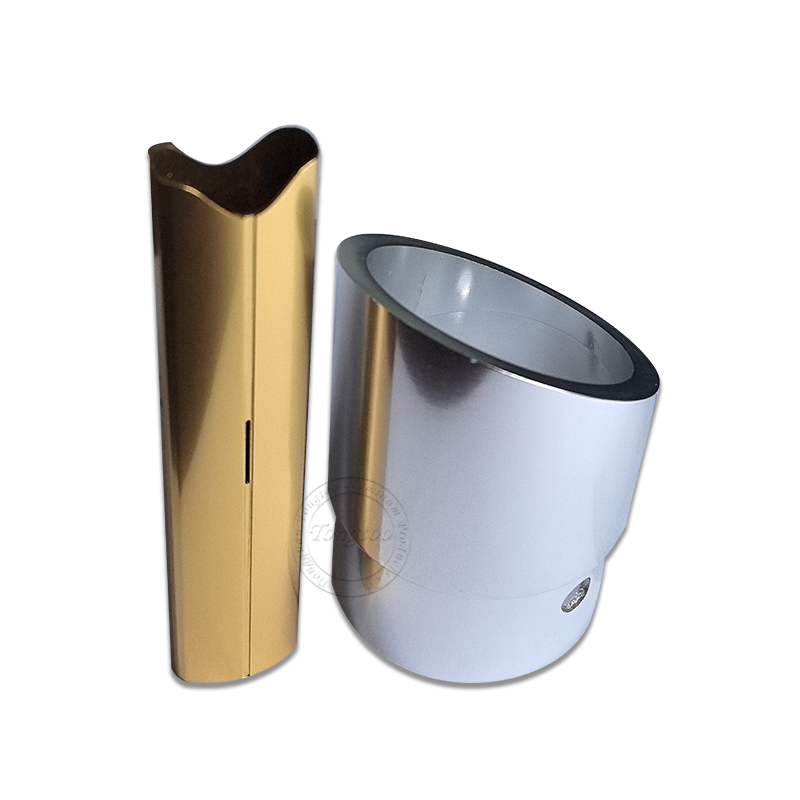

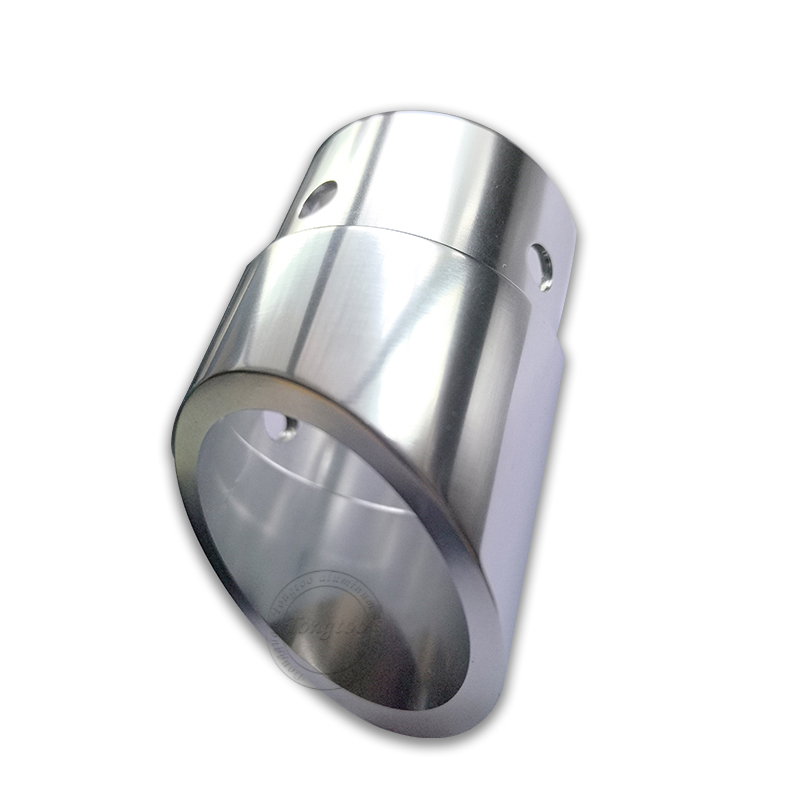

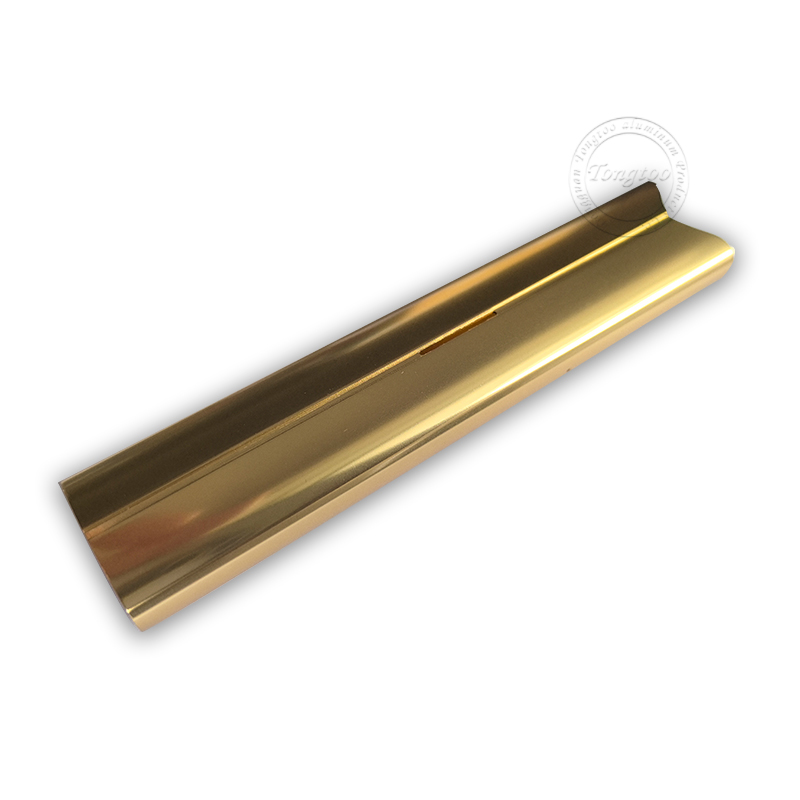

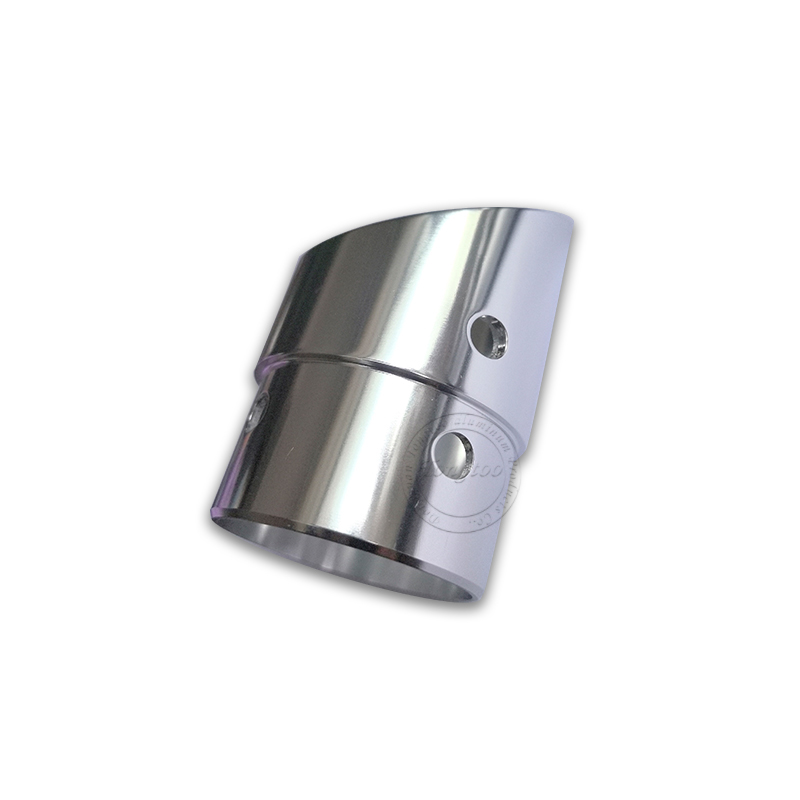

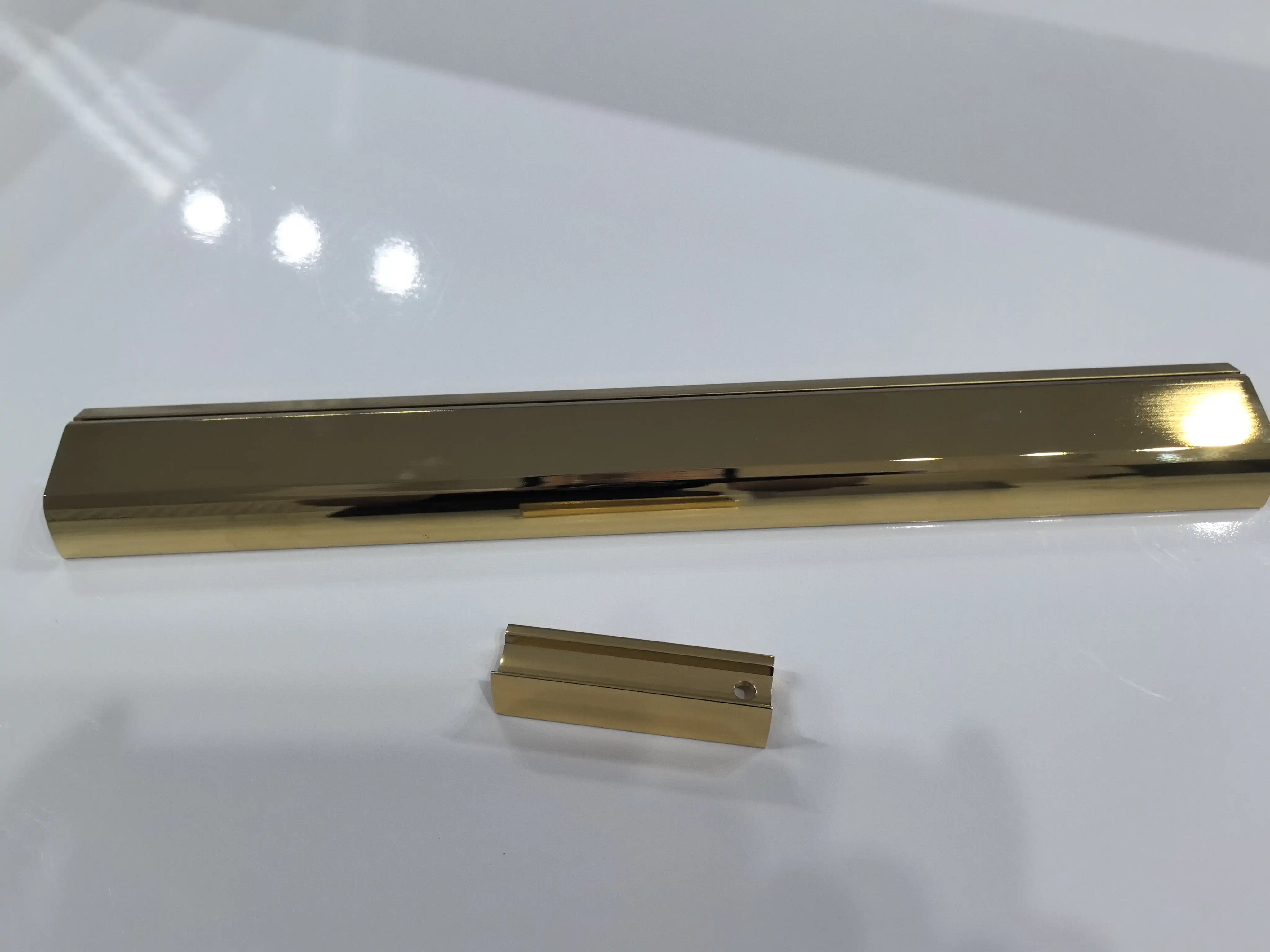

CNC Machining with Mirror Surface Finish

We specialize in providing industry-leading mirror finishing services for metal surfaces. We utilize advanced precision polishing and ultra-fine grinding technologies to give your products a flawless, mirror-like finish, reminiscent of works of art.

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. specializes in aluminum alloy CNC precision machining, injection molding, mold development, and metal manufacturing. We are ISO 9001 certified and strictly implement the 6S management system. Using equipment imported from Germany, our products are exported to over 20 countries, including Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million units. With exquisite craftsmanship, rapid response, and end-to-end quality inspection at our core, we provide customized ODM/OEM solutions to our global customers, striving to become a trusted strategic partner in the international industrial manufacturing sector.

Product Introduction

We specialize in providing industry-leading mirror finishing services for metal surfaces. We utilize advanced precision polishing and ultra-fine grinding technologies to give your products a flawless, mirror-like finish, reminiscent of works of art. Widely used in medical devices, food processing machinery, high-end home appliances, automotive parts, and semiconductor equipment, our services significantly enhance product corrosion resistance, cleanliness, and aesthetic value, helping your brand shine in the global market.

Product Description: What is Mirror Finishing?

Mirror finishing is an ultra-high-precision surface treatment process that uses a series of physical or chemical methods to achieve an extremely smooth, mirror-like surface finish. Surface roughness (Ra) values can reach Ra ≤ 0.01 μm, resulting in extremely high reflectivity and clear, distortion-free images. This is achieved not only for aesthetic reasons but also to meet functional requirements such as high cleanliness standards, reduced friction coefficients, and enhanced anti-adhesion and corrosion resistance.

Product Features and Applications

Our Technical Advantages and Process Features

Multi-Step Precision Polishing Process: Utilizing a comprehensive process from rough grinding to fine polishing, including mechanical polishing, chemical polishing, and electropolishing, we customize the optimal solution for each material and customer's needs, ensuring a surface free of orange peel, scratches, and flaws.

Advanced 8K Ultra-Mirror Technology: Utilizing industry-leading 8K mirror processing technology, stainless steel and other metal surfaces achieve ultra-high-definition reflective effects comparable to display screens, highlighting the product's ultimate high-end quality.

Wide Material Compatibility: We specialize in processing a variety of metal materials, including 304/316 stainless steel, mold steel, aluminum alloy, copper alloy, and titanium alloy, to meet the specific needs of various industries.

Perfect Blend of Function and Aesthetics: Our mirror finish not only achieves a high reflectivity visual effect, but also significantly improves the workpiece's corrosion resistance, ease of cleaning, and anti-stick properties, making it particularly suitable for applications requiring the highest hygiene standards. Expert Team: Our team of engineers with over ten years of experience provides technical consultation and solutions.

Customized Service: We offer a free surface treatment solution evaluation based on your workpiece shape, material, and end use.

Competitive Pricing: Our large-scale production and efficient management provide you with cost-effective mirror finishing services.

Application Areas

Medical Devices and Pharmaceutical Equipment: Surgical instruments, implants, reactors, and stirring rods, ensuring a sterile environment that meets FDA and GMP standards.

Food and Beverage Industry: Food processing equipment, filling machines, milk tanks, and kitchen utensils, ensuring hygiene and safety to prevent bacterial growth.

High-end Home Appliances and Home Furnishings: Elevator interiors, appliance panels, sinks, and faucets, enhancing product quality and design.

Automotive and Aerospace: Automotive trim, turbine blades, and sensor components, reducing drag and meeting stringent performance requirements. Semiconductor and Precision Manufacturing: Wafer handling robots, vacuum chambers, and precision molds, eliminating dust contamination.

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (production process quality control)

Testing Equipment: Zeiss 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

A professional ODM & OEM manufacturer with over 20 years of precision machining experience. We provide comprehensive, customized services tailored to customer needs.

|

|

|

Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/PEF + wooden box

Global Export Experience: Familiar with international packaging and shipping standards, we consistently supply products to global markets including Europe, America, Japan, and South Korea.

FAQ

Q1: What design file formats do you handle?

A: We accept nearly all major 3D formats, including STEP (.stp), IGES (.igs), SolidWorks (.sldprt), and Parasolid (.x_t), as well as 2D drawing formats such as PDF and DXF. To ensure accuracy, we strongly recommend that you also provide standard engineering drawings with complete dimensions, tolerances, and technical requirements.

Q2: How long does it take from receiving your documents to receiving a quote?

A: For most inquiries, we offer a quick quote within 24 hours. For particularly complex parts, we may require additional time for process review, but we will communicate this promptly.

Q3: What is your minimum order quantity (MOQ)?

A: We do not have a strict MOQ. We support single-piece prototypes and small trial runs, as well as large-volume production orders. For small-volume orders, pricing is primarily based on processing time and material costs.

Q4: How do you guarantee part quality?

A: We conduct full-process quality inspections. From first article inspection (FAI) to in-process spot checks, we use precision inspection equipment such as coordinate measuring machines (CMMs), 2D image measuring machines, calipers, and micrometers to perform 100% inspection of critical dimensions and provide comprehensive inspection reports.

Q5: What is a typical production cycle?

A: Production cycle time depends on part complexity and order quantity. Typically, prototypes take 3-7 business days, while production runs require an assessment based on specific quantities. We will provide you with an accurate production and delivery schedule when quoting. Q6: Do you offer global logistics services?

A: Yes, we can provide reliable and efficient logistics and delivery services to our customers worldwide.

Company Introduction

Our 5,000 square meter workshop is equipped with hundreds of CNC machining centers (with machining accuracy up to 0.002 mm), CNC turning and milling machines, CNC lathes, milling machines, lathes, grinders, and more; as well as over a dozen inspection equipment (with inspection accuracy up to 0.001 mm). Our machining capabilities reach internationally advanced levels. The Tengtu team possesses the most professional expertise in mold design and CNC machining. We will work closely with you throughout prototyping, production, assembly, inspection, packaging, and final delivery to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts for industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with exceptional precision, tight tolerances, and premium materials. Over the past 11 years, Tengtu has established a strong reputation for efficiency, quality, reliability, and on-time delivery.