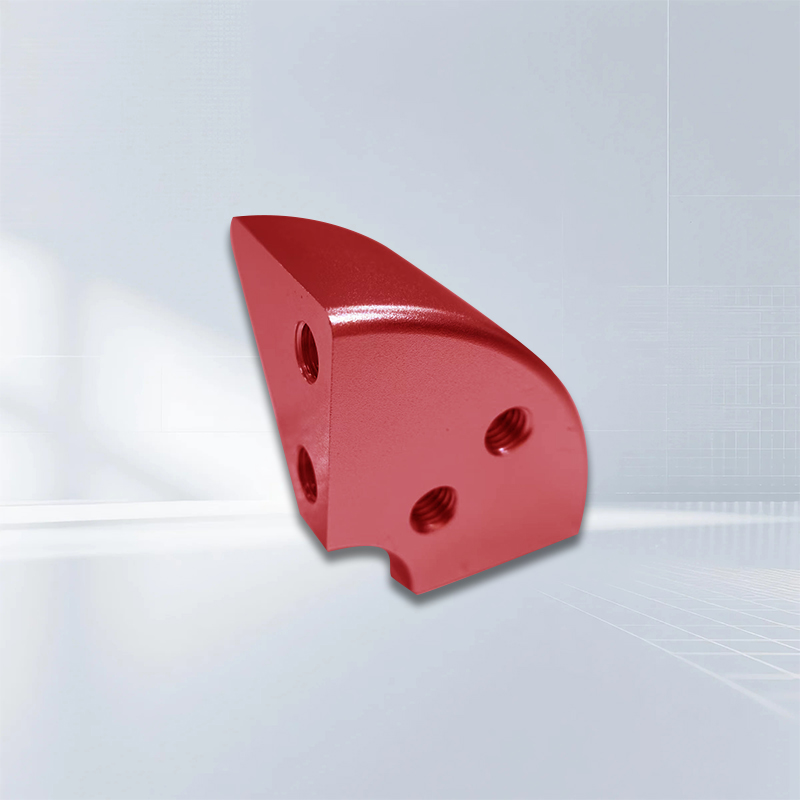

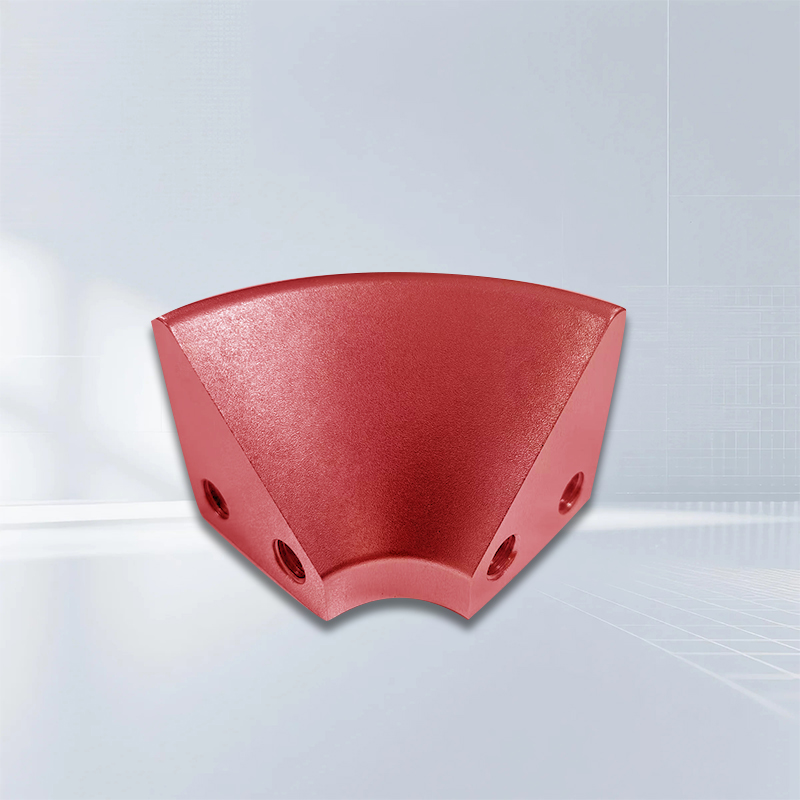

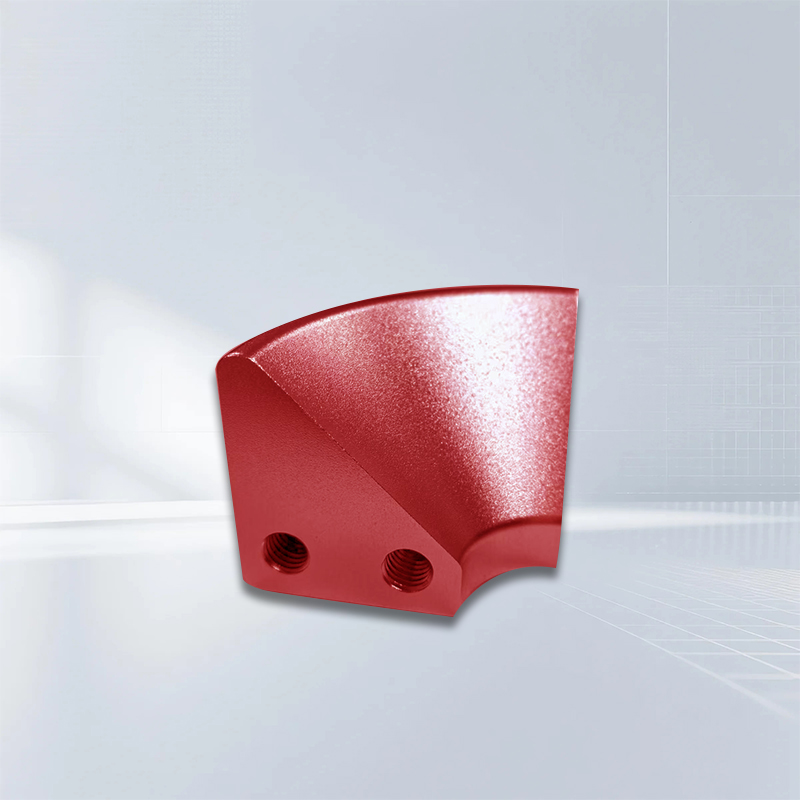

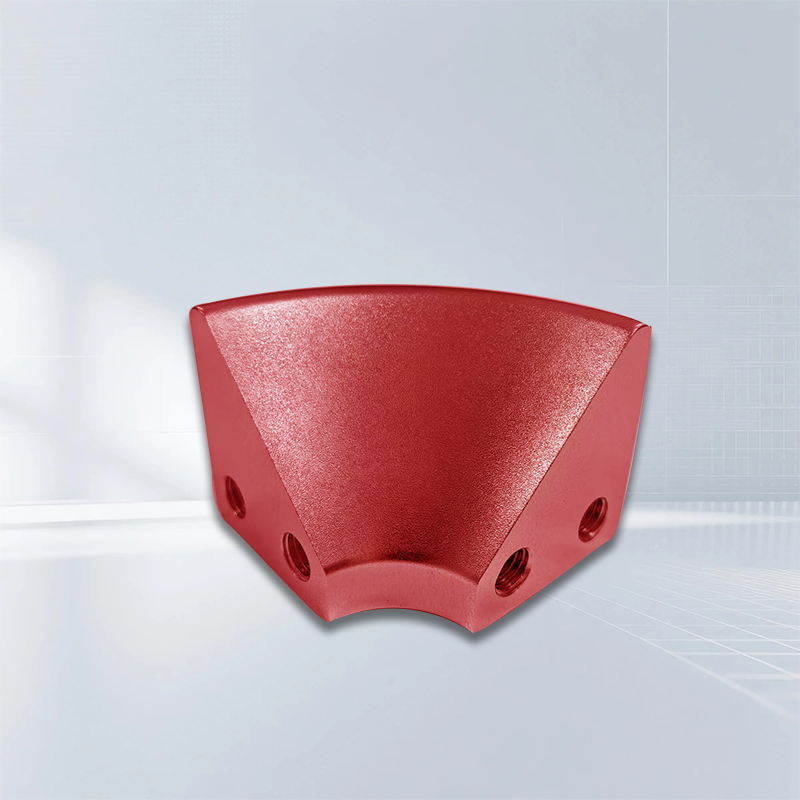

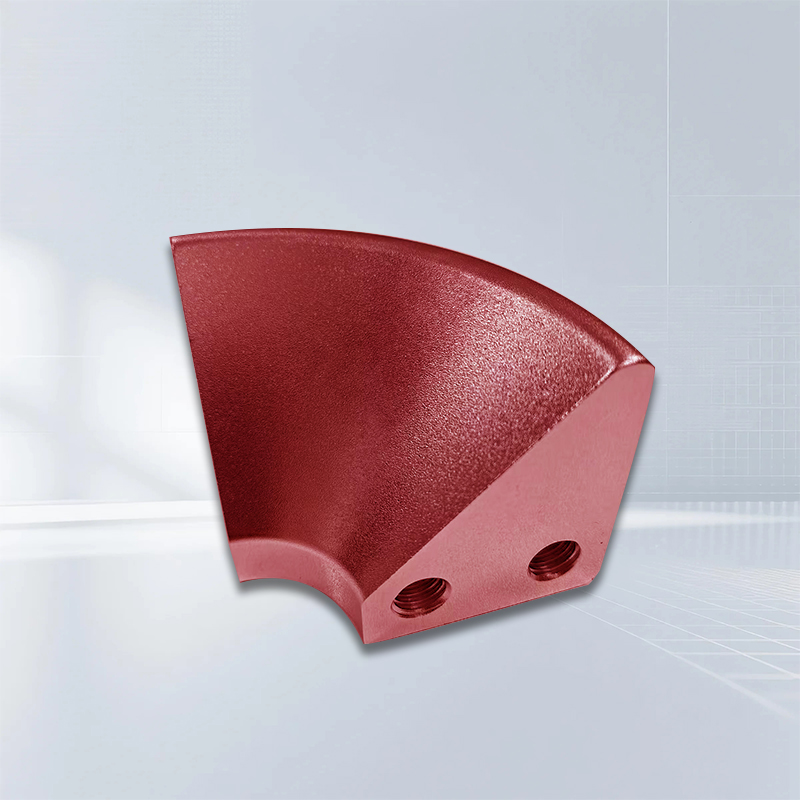

CNC Machined Mechanical Equipment Components

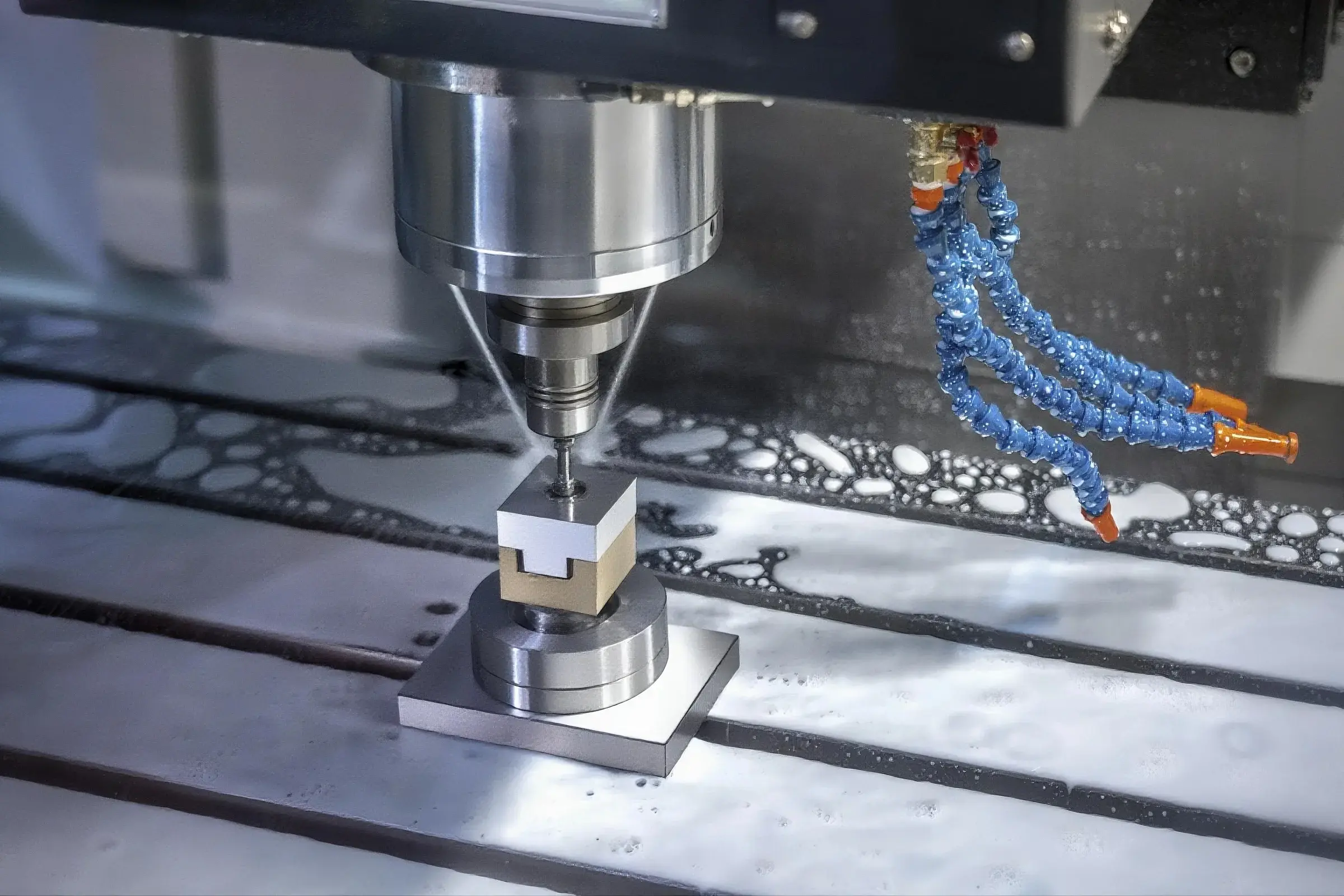

Our high-precision CNC machining services specialize in providing top-tier customized metal and plastic parts for the manufacturing industry. Leveraging advanced multi-axis CNC milling, CNC turning, and multi-processing technologies, we transform your design drawings into high-performance, dimensionally accurate parts.

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. specializes in aluminum alloy CNC precision machining, injection molding, mold development, and metal manufacturing. We are ISO 9001 certified and strictly implement the 6S management system. Using equipment imported from Germany, our products are exported to over 20 countries, including Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million units. With exquisite craftsmanship, rapid response, and end-to-end quality inspection at our core, we provide customized ODM/OEM solutions to our global customers, striving to become a trusted strategic partner in the international industrial manufacturing sector.

Product Introduction

Our high-precision CNC machining services specialize in providing top-tier customized metal and plastic parts for the manufacturing industry. Leveraging advanced multi-axis CNC milling, CNC turning, and multi-processing technologies, we transform your design drawings into high-performance, dimensionally accurate parts. Whether for prototyping or mass production, we offer a one-stop solution from material selection, precision machining, and surface treatment, making us your trusted CNC parts supplier and manufacturing partner.

Product Specifications

Core Material Capabilities:

Metals: Aluminum alloy, stainless steel (304, 316), carbon steel, brass, copper, titanium alloy, etc.

Plastics: POM, nylon (PA), PC, PEEK, ABS, etc.

Product Features and Applications of the CNC Machinery Parts

Core Advantages and Features

1. Ultimate Precision and Consistency

We utilize top-tier CNC machine tools from Germany and Japan, achieving positioning accuracy of ±0.002mm. Strict quality control systems and end-to-end quality control ensure that every batch of parts, from the first to the ten thousandth, maintains incredible consistency and exceptional precision, perfectly meeting your design specifications.

2. Strong Material and Process Capabilities

We stock over 100 types of metal and engineering plastic raw materials, meeting your requirements for varying strength, hardness, corrosion resistance, and specialized applications. We also offer a wide range of post-production surface treatment services, including:

Anodizing (colorable); Hard anodizing; Electroplating (nickel, chrome, zinc); Sandblasting and polishing; Heat treatment (quenching, carburizing); Spraying

3. Fast Response and Flexible Production: We deeply understand the importance of rapid prototyping and shortening time to market. Leveraging automated programming systems and efficient production processes, we can provide 24-hour fast quotes and small-batch rapid prototyping services, accelerating your R&D and iteration processes. Furthermore, our production capacity can be seamlessly scaled to large-scale production to meet your needs at every stage.

4. Support from a Team of Technical Experts: Our experienced team of engineers and technicians not only possesses mastery of machining techniques but can also provide design optimization advice. 5. Competitive Pricing and Reliable Delivery: Through optimized production processes and supply chain management, we guarantee top-tier quality while offering competitive pricing. We adhere to strict delivery deadlines and utilize a comprehensive logistics system to ensure your orders are delivered on time and in good condition worldwide.

Applications

Our CNC precision parts are widely used in industries that demand the highest quality, reliability, and precision:

Aerospace: Aircraft interior components, sensor housings, drone frames, and navigation equipment parts. Medical Devices: Surgical instrument handles, endoscope parts, diagnostic equipment housings, implant prototypes

Industrial Automation and Robotics: Robotic arm joints, guide rails and sliders, custom fixtures, connectors, and sensor holders

Communications and Electronics: 5G base station heat sinks, RF device housings, test fixtures, and chip test sockets

Energy Industry: Oil and gas exploration parts, solar panel mountings, and wind turbine components

Product Qualification of CNC Machinery Parts

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (production process quality control)

Testing Equipment: Zeiss 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

A professional ODM & OEM manufacturer with over 20 years of precision machining experience. We prioritize customer needs and provide comprehensive customized services.

|

|

|

Standard packaging: Copy paper + cardboard

Custom packaging: Blister tray/PEF + wooden box

FAQ

Q1: What design file formats do you accept?

A: We accept nearly all major 3D formats, including STEP (.stp), IGES (.igs), SolidWorks (.sldprt), and Parasolid (.x_t), as well as 2D drawing formats such as PDF and DXF. To ensure accuracy, we strongly recommend that you also provide standard engineering drawings with complete dimensions, tolerances, and technical requirements.

Q2: How long does it take from receiving the file to receiving a quote?

A: For most inquiries, we provide a quick quote within 24 hours. For particularly complex parts, we may require additional time for process review, but we will communicate this promptly.

Q3: What is the minimum order quantity (MOQ)?

A: We do not have a strict MOQ. We support single-piece prototypes and small-batch trial runs, as well as large-volume production orders. For small-batch orders, pricing is primarily based on processing time and material costs.

Q4: How do you ensure part quality?

A: We implement comprehensive quality inspection throughout the entire process. From first article inspection (FAI) to in-process spot checks, we use precision inspection equipment such as coordinate measuring machines (CMMs), 2D image measuring machines, calipers, and micrometers to perform 100% inspection of critical dimensions and provide comprehensive inspection reports.

Q5: What is your typical production lead time?

A: Production lead time depends on part complexity and order quantity. Typically, prototypes take 3-7 business days, while production runs require a specific quantity estimate. We will provide you with an accurate production and delivery schedule when providing a quote. Q6: Do you offer global logistics services? A: Yes, we can provide reliable and efficient logistics and delivery services to customers worldwide.

Company Introduction

Our 5,000 square meter workshop is equipped with hundreds of CNC machining centers (with machining accuracy up to 0.002 mm), CNC turning and milling machines, CNC lathes, milling machines, lathes, grinders, and more; as well as over a dozen inspection equipment (with inspection accuracy up to 0.001 mm). Our machining capabilities reach internationally advanced levels. The Tengtu team possesses the most professional expertise in mold design and CNC machining. We will work closely with you throughout prototyping, production, assembly, inspection, packaging, and final delivery to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts for industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with exceptional precision, tight tolerances, and premium materials. Over the past 11 years, Tengtu has established a strong reputation for efficiency, quality, reliability, and on-time delivery.