Medical Grade Precision CNC Machining

Tongtoo Aluminum Products Co., Ltd. offers precision parts manufacturing services, encompassing aluminum profile mold design, mold making, extrusion, CNC machining, stamping, polishing, anodizing, and other processes. We support one-stop mass production, from design drawing to finished product delivery, meeting the needs of various industries, including industrial equipment, automotive parts, aerospace, electronics, communications, and medical devices.

Product Description

Product Introduction

Tongtoo Aluminum Products Co., Ltd. offers precision parts manufacturing services, encompassing aluminum profile mold design, mold making, extrusion, CNC machining, stamping, polishing, anodizing, and other processes. We support one-stop mass production, from design drawing to finished product delivery, meeting the needs of various industries, including industrial equipment, automotive parts, aerospace, electronics, communications, and medical devices.

Product Parameters

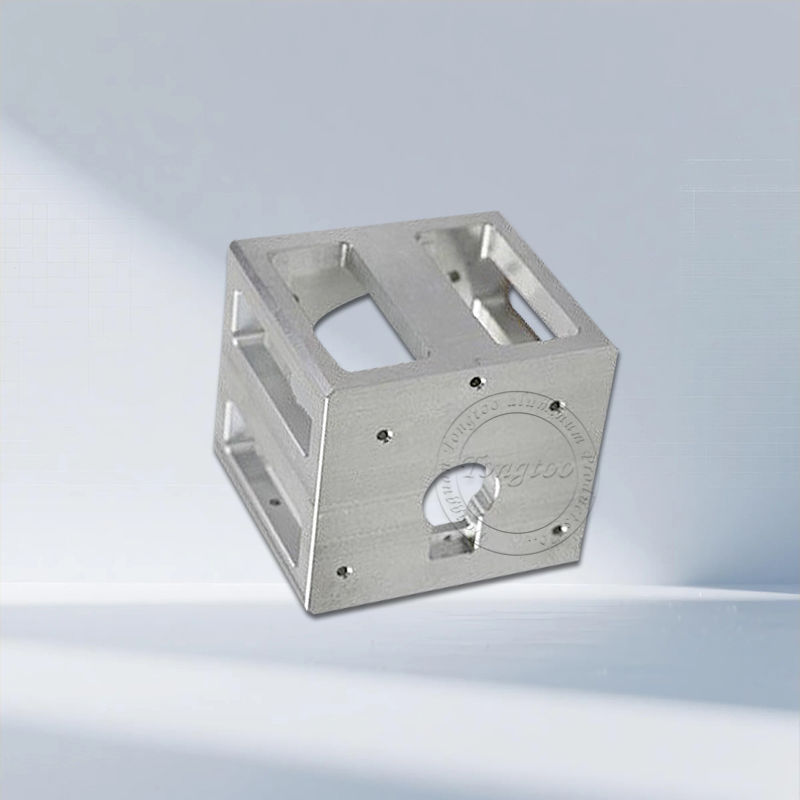

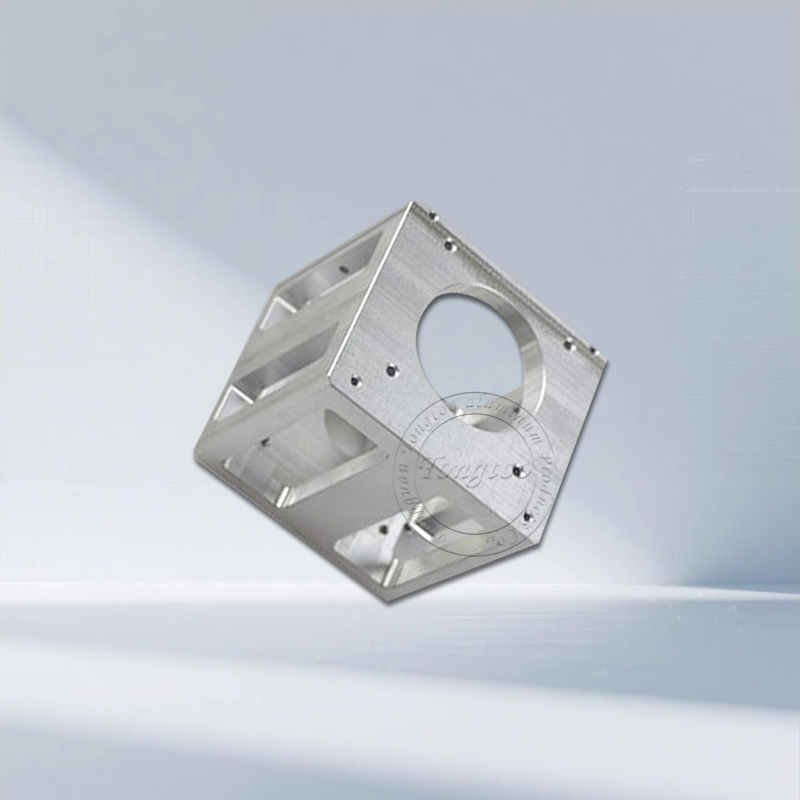

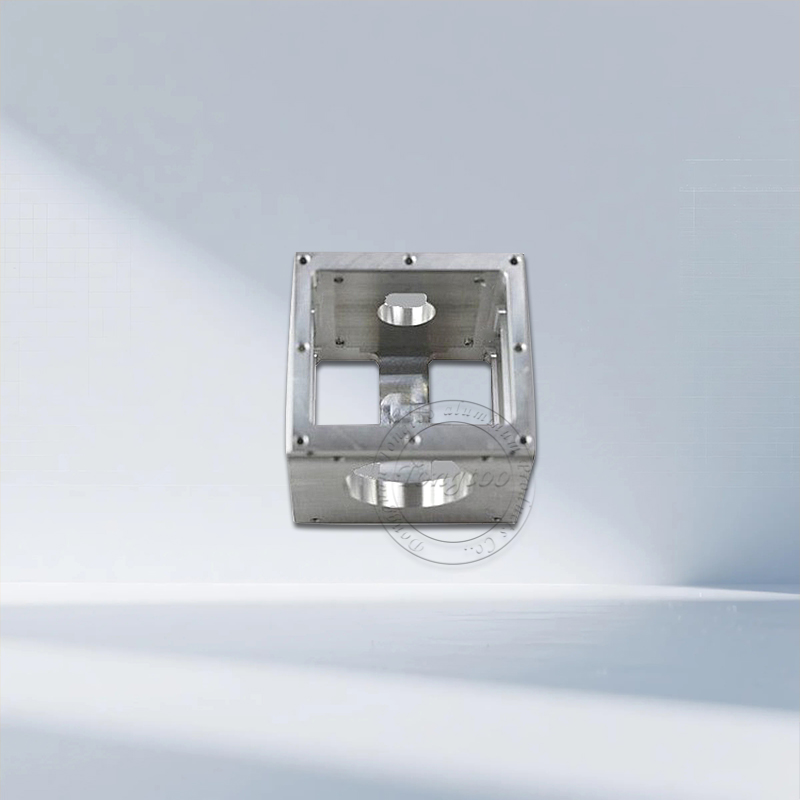

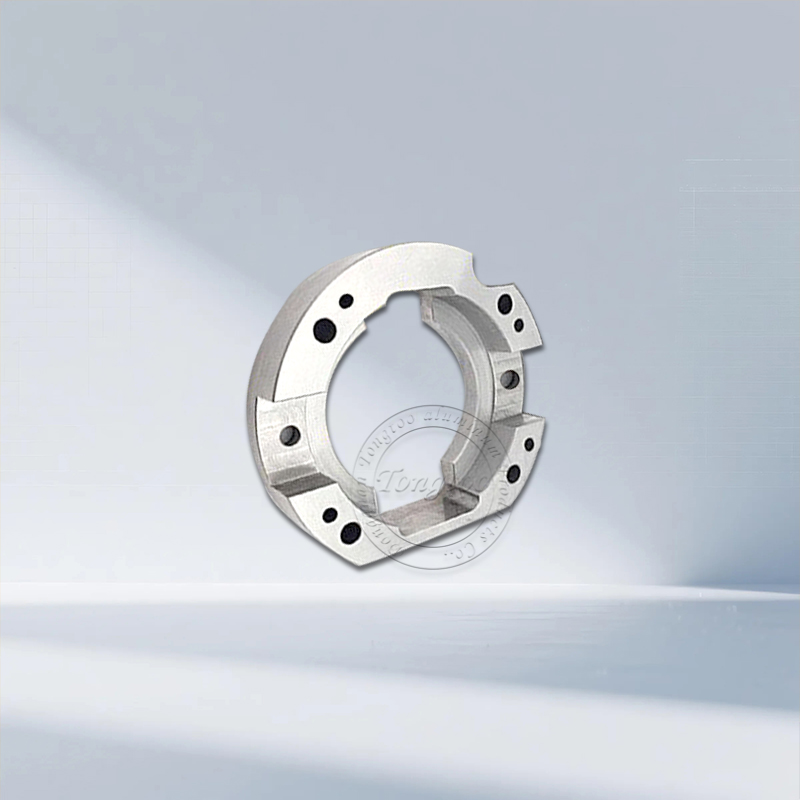

Product Name: Medical-Grade Precision CNC Machining

Material: 6061/Titanium Alloy/Stainless Steel/Medical-Grade PEEK, etc.

Processing: Extrusion/CNC Machining/Milling/Stamping/Die-Casting

Surface Treatment: Anodizing/Hard Oxidation/Powder Coating/Laser Engraving

Features: Customizable holes, dimensions, and logos

Product Feature and Application

High-Precision Machining

Equipment: Imported CNC machine tools, high-precision CNC lathes, automated production lines

Tolerance: Standard ±0.01mm, up to ±0.005mm

Surface Treatment: Anodizing (matte/glossy), sandblasting, electroplating, powder coating, laser engraving, etc.

Mass Production and Efficient Delivery

Monthly Production Capacity: Over 500,000 pieces (depending on part complexity)

Delivery Time: 3-7 days for proofing, 10-25 days for mass orders (expedited processing available)

Quick mold creation reduces costs for small-batch trial production. Strict quality control system and ISO certification throughout the entire process. 9001 Quality Management Certification

100% Full Inspection + Full-Process Quality Control

Material and Dimensional Inspection Reports Provided

Medical-Grade Precision CNC Machining Applications

Automotive: Engine components, brackets, housings, etc.

Electronic Equipment: Precision parts such as heat sinks, housings, and connectors

Medical: Smart medicine cabinet components, nurse station carts, surgical robot components, medical sensor housings, precision ventilator components, and testing instrument frames

Aerospace: Lightweight components and aviation plug-in accessories

Smart Hardware: Robot joints and drone frames

LED: Precision parts such as aluminum lamp housings, heat sinks, heat dissipation housing profiles, and desk lamp bases

Product Details

High Efficiency and Fast Response:

Digital machining processes (CAD/CAM programming) shorten production setup time.

Suitable for rapid small-batch proofing and verification, as well as stable medium- and large-volume production.

Quickly respond to customer needs and shorten product time-to-market.

Strict Quality Control: ISO quality management system certification (such as ISO 9001) is implemented throughout the entire production process. Equipped with precision testing equipment (such as coordinate measuring machines/CMMs, 2D imagers, hardness testers, film thickness gauges, and salt spray testers), we conduct rigorous incoming material inspection (IQC), in-process inspection (IPQC), and finished product inspection (FQC/OQC). This ensures that products meet dimensional accuracy, form and position tolerances, surface quality, and performance requirements.

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (EU Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production Process Quality Control)

Delivery, Shipping, and Serving

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive, customized services tailored to customer needs.

|

|

|

Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/PEF + wooden box

FAQ

Q:What materials do you primarily process? Which is the most commonly used?

A: We most commonly machine 6061-T6 aluminum alloy due to its excellent overall performance (strength, machinability, corrosion resistance, and surface treatment capabilities) and cost-effectiveness. We also offer other materials, such as titanium alloy TC4/GR5, 316L stainless steel, and medical-grade PEEK.

Q: What is the achievable accuracy of CNC machining?

A: Standard machining accuracy is typically ±0.05mm. For more demanding features, we can achieve ±0.01mm or even higher accuracy through precision equipment and process control. The actual achievable accuracy depends on the specific part structure, size, feature complexity, and the equipment and process used. We will discuss the tolerance requirements in detail with you before quoting.

Q: What is the minimum order quantity for a small trial run?

A: The minimum order is 1 piece, and prototypes can be delivered within 5-15 days. Iterative modifications are supported. For batches of up to 1,000 pieces, unit costs can be reduced by 30% or more.

Q: How long does it take from order placement to delivery? A: Production lead times depend on part complexity, quantity, and current order schedules.

Simple parts/small batch prototyping: Typically approximately 3-7 business days.

Complex parts/medium batches: May take 1-3 weeks.

Large-volume production: This will be assessed based on specific production capacity, typically 2-6 weeks or longer. We will promptly review and provide you with an accurate lead time upon receipt of the drawings or 3D models.

Q: What documents do I need for a quote and production?

A: Please provide clear, complete 2D engineering drawings (PDF/DWG/DXF) or 3D model files (STEP/IGES/SLDPRT/X_T, etc.). The drawings/models must include: Detailed dimensioning and tolerance requirements; Specified material grades; Surface finish requirements (type, color, thickness, etc.); Quantity; and any special requirements (such as special testing, packaging, etc.). The more accurate and detailed the information provided, the smoother and more efficient the quote and production process.

Q: Will the machined part have burrs? How should this be addressed?

A: Burrs may be generated during CNC machining. We have a strict deburring process, using methods such as manual deburring, vibration grinding, and magnetic polishing to ensure that the edges of the parts delivered to you are smooth and meet the requirements of the drawings, ensuring safe use and smooth assembly.