CNC Medical Parts

Tongtoo Aluminum Products Co., Ltd. specializes in providing customized CNC machining services for high-quality, high-precision aluminum alloy components. We utilize premium aluminum alloys (such as 6061-T6, 7075-T6, and 5052) and utilize advanced CNC machining centers and rigorous quality control procedures. We offer CNC machining services for medical components, including precision machining of titanium, stainless steel, PEEK, and aluminum alloys with ±0.01mm tolerances and cleanroom packaging. Supports mass production of surgical instrument and implant prototypes, with fast 15-day delivery and full document traceability.

Product Description

Product Introduction

Tongtoo Aluminum Products Co., Ltd. specializes in providing customized CNC machining services for high-quality, high-precision aluminum alloy components. We utilize premium aluminum alloys (such as 6061-T6, 7075-T6, and 5052) and utilize advanced CNC machining centers and rigorous quality control procedures. We offer CNC machining services for medical components, including precision machining of titanium, stainless steel, PEEK, and aluminum alloys with ±0.01mm tolerances and cleanroom packaging. Supports mass production of surgical instrument and implant prototypes, with fast 15-day delivery and full document traceability.

Product Parameters

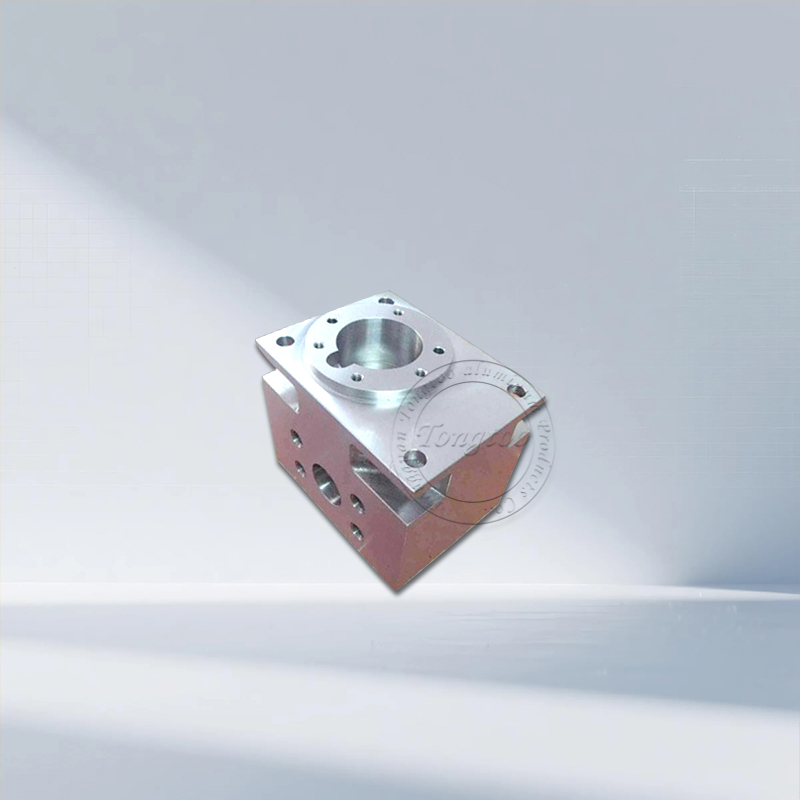

Product Name: High-Precision CNC Machining of Medical Device Parts

Material: 6061, Titanium Alloy, Stainless Steel, Medical-Grade PEEK, etc.

Processing: Die Extrusion, CNC Machining, Milling/Turning, Stamping, Die Casting

Surface Treatment: Anodizing, Hard Oxidation, Powder Coating, Laser Engraving

Product Features: Customizable holes, dimensions, and logos

Product Features and Applications

Excellent Precision and Consistency:

Utilizing high-precision CNC machine tools (three-, four-, and five-axis linkage), we ensure strict part dimensional tolerances of ±0.01mm to ±0.05mm (or as per drawing requirements), meeting precision assembly requirements.

CNC programming ensures high consistency during mass production and reduces manual errors. High-precision flat/cavity parts: surgical forceps frames, detector baseplates, implant fixation plates

Efficient machining of rotationally symmetrical parts: arthroscopic cannulas, dental guide rods, insulin pen parts

Tolerance control: ±0.01mm (critical dimensions)

Excellent surface finish:

Processing results in excellent surface roughness (typically Ra 0.4μm - Ra 3.2μm).

Provides a high-quality base surface for subsequent surface treatments (such as anodizing, sandblasting, painting, electroplating, conductive oxidation, and laser engraving).

Application Scenarios

Surgical Instruments

Endoscope Metal Structural Parts • Needle Holder Joints • Minimally Invasive Surgical Forceps • Electrosurgical Generator Insulation Sleeves

Diagnostic Equipment

Biochemical Analyzer Sample Stages • CT Sliders • Blood Test Clips • Ultrasound Probe Housings

Implants and Rehabilitation Devices

Orthopedic Positioning Guides (Prototypes) • Denture Implant Abutments • Prosthetic Joints • External Fixator Accessories

Medical Equipment

Nurse Station Cart Structural Parts • Smart Medicine Cabinet Aluminum Profiles • Surgical Light Components

Product Details

High Efficiency and Fast Response:

Digital machining processes (CAD/CAM programming) shorten production setup time.

Suitable for rapid small-batch prototyping and verification, they also support stable medium- and large-volume production.

Quickly respond to customer needs and shorten product time-to-market.

Strict Quality Control: ISO quality management system certification (such as ISO 9001) is implemented throughout the entire production process. Equipped with precision testing equipment (such as coordinate measuring machines/CMMs, 2D imagers, hardness testers, film thickness gauges, and salt spray testers), we conduct rigorous incoming material inspection (IQC), in-process inspection (IPQC), and finished product inspection (FQC/OQC). This ensures that products meet dimensional accuracy, form and position tolerances, surface quality, and performance requirements.

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (EU Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production Quality Control)

Delivery, Shipping, and Serving

As a professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive, customized services tailored to customer needs.

|

|

|

Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/PEF + wooden box

FAQ

Q: What materials do you primarily process? Which is the most commonly used?

A: We most commonly machine 6061-T6 aluminum alloy due to its excellent overall performance (strength, machinability, corrosion resistance, and surface treatment capabilities) and cost-effectiveness. We also offer other materials, such as titanium alloy TC4/GR5, 316L stainless steel, and medical-grade PEEK.

Q: What is the achievable accuracy of CNC machining?

A: Standard machining accuracy is typically ±0.05mm. For more demanding features, we can achieve ±0.01mm or even higher accuracy through precision equipment and process control. The actual achievable accuracy depends on the specific part structure, dimensions, feature complexity, and the equipment and processes used. We will discuss the tolerance requirements in detail with you before quoting.

Q: What is the minimum order quantity for a small trial run?

A: We have a minimum order of 1 piece, and prototypes are delivered within 5-15 days. Iterative modifications are supported. For batches of up to 1,000 pieces, we can achieve a 30%+ reduction in unit cost.

Q: How long does it take from order placement to delivery?

A: The production lead time depends on the complexity and quantity of the part, as well as the current order schedule. Simple parts/small batch prototyping: Typically approximately 3-7 business days.

Complex parts/medium batches: May take 1-3 weeks.

Large-volume production: This will be assessed based on specific production capacity, typically 2-6 weeks or longer. We will promptly review and provide you with an accurate delivery time upon receiving the drawings or 3D models.

Q: What documents do I need for a quote and production?

A: Please provide clear, complete 2D engineering drawings (PDF/DWG/DXF) or 3D model files (STEP/IGES/SLDPRT/X_T, etc.). The drawings/models must include: Detailed dimensioning and tolerance requirements; Specified material grades; Surface finish requirements (type, color, thickness, etc.); Quantity; Any special requirements (such as special testing, packaging, etc.). The more accurate and detailed the information provided, the smoother and more efficient the quote and production process.

Q: Will the machined part have burrs? How are they addressed?

A: Burrs may be generated during CNC machining. We have a strict deburring process, using methods such as manual deburring, vibration grinding, and magnetic polishing to ensure that the edges of the parts delivered to you are smooth, meet the requirements of the drawings, and ensure safe use and smooth assembly.