High Precision Thin-Walled Parts Manufacturing Expert

Tongtoo Aluminum Products Co., Ltd. specializes in providing high-quality, high-precision customized CNC machining services for 7075 aluminum alloy parts. Using premium aluminum alloys (such as 6061-T6, 7075-T6, and 5052), combined with advanced CNC machining centers and rigorous quality control processes, we offer CNC machining services for aerospace parts. We offer precision machining of titanium, stainless steel, PEEK, and aluminum alloys with ±0.01mm tolerances. We support both prototype and mass production, with fast delivery within 15 days and full document traceability.

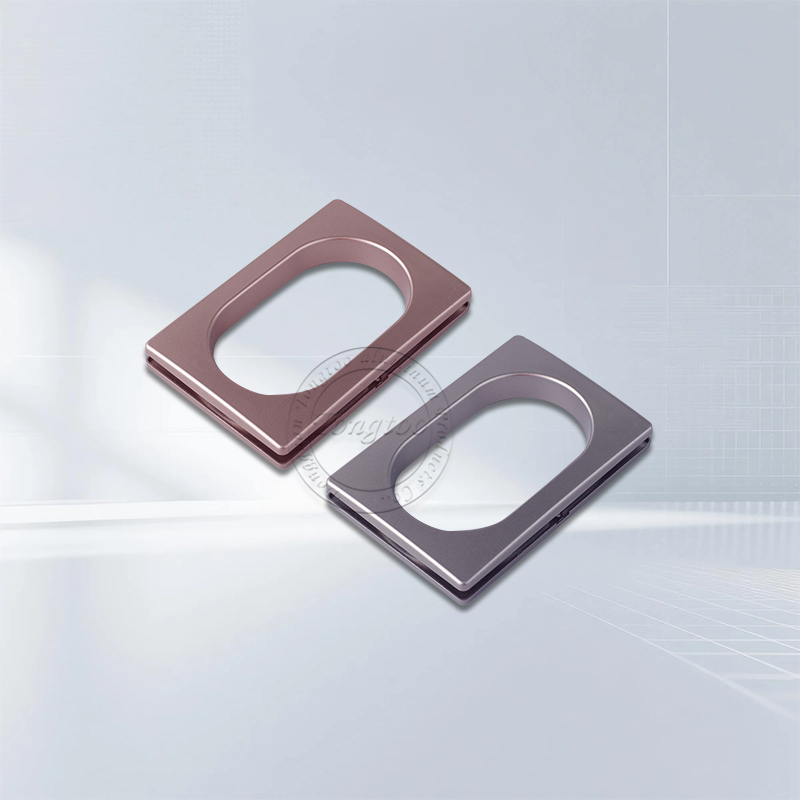

Product Description

Product Introduction

Tongtoo Aluminum Products Co., Ltd. specializes in providing high-quality, high-precision customized CNC machining services for 7075 aluminum alloy parts. Using premium aluminum alloys (such as 6061-T6, 7075-T6, and 5052), combined with advanced CNC machining centers and rigorous quality control processes, we offer CNC machining services for aerospace parts. We offer precision machining of titanium, stainless steel, PEEK, and aluminum alloys with ±0.01mm tolerances. We support both prototype and mass production, with fast delivery within 15 days and full document traceability.

Product Parameters

Product Name: CNC Machining of Aerospace Aluminum Parts

Material: Aluminum Alloy, Titanium Alloy, Stainless Steel, etc.

Processing: Die Extrusion / CNC Machining / Milling/Stamping / Die Casting

Surface Treatment: Anodizing / Hard Anodizing / Powder Coating / Laser Engraving

Product Features: Customizable cutouts, dimensions, and logos

Product Features and Applications

Technical Highlights

1. Extreme Precision Control

Utilizing a German five-axis CNC center (DMG/Mazak)

Achieving ultra-high tolerances of ±0.005mm, meeting the demanding assembly requirements of aircraft engine mounts, satellite interface components, and more. Thin-wall machining starting at 0.3mm with anti-deformation technology.

2. Aviation-Specific Material Experience

American Standard materials such as 7075-T6/6061-T6/2024 are readily available in stock.

Titanium-aluminum composite machining capabilities address thermal expansion coefficient discrepancies.

3. Special Structural Solutions

Deep Cavity Machining (15:1 aspect ratio) » Milling of Contoured Surfaces » Tooling-Free Polyhedron Machining

Mirror Finishing (Ra ≤ 0.2μm) » Anti-static Treatment » Stress-Free Clamping Technology

Applications

Aircraft: Cabin Structural Parts · Landing Gear Components · Avionics Mounting Brackets · Fuel System Components 🛰

Aerospace: Satellite Frames · Rocket Engine Cases · Space Station Interface Components 🚀 Drone: Lightweight Airframe · Gimbal Bracket · Power Compartment

Product Details

High Efficiency and Rapid Response:

Digital processing (CAD/CAM programming) shortens production setup time.

It is suitable for rapid proofing and verification of small batches, and also supports stable production of medium and large batches.

Quickly respond to customer needs and shorten product launch time.

Strict Quality Control: ISO quality management system certification (such as ISO 9001) is implemented throughout the entire production process. Equipped with precision testing equipment (such as coordinate measuring machines/CMMs, 2D imagers, hardness testers, film thickness gauges, and salt spray testers), we conduct rigorous incoming material inspection (IQC), in-process inspection (IPQC), and finished product inspection (FQC/OQC). This ensures that products meet dimensional accuracy, geometric tolerances, surface quality, and performance requirements.

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (EU Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production Process Quality Control)

Delivery, Shipping, and Serving

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive customized services tailored to customer needs.

|

|

|

Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/PEF + wooden box

FAQ

Q: What is the achievable CNC machining accuracy?

A: Standard machining accuracy is typically ±0.05mm. For more demanding features, we can achieve ±0.01mm or even higher accuracy through precision equipment and process control. The actual achievable accuracy depends on the specific part structure, dimensions, feature complexity, and the equipment and process used. We will discuss the tolerance requirements with you in detail before quoting.

Q: What is the minimum order quantity for a small trial run?

A: With a minimum order of 1 piece, prototypes are delivered within 5-15 days, and we support iterative modifications. For batches of up to 1,000 pieces, unit costs are reduced by 30% or more.

Q: How long does it take from order placement to delivery?

A: Production lead time depends on part complexity, quantity, and current order schedules.

Simple parts/small batch prototypes: Typically approximately 3-7 business days.

Complex parts/medium batches: May take 1-3 weeks.

Large-volume production: This will require a specific capacity assessment, typically 2-6 weeks or longer. We will promptly assess and provide you with an accurate delivery time upon receiving the drawings or 3D models.

Q: What documents do I need for a quote and production?

A: Please provide clear, complete 2D engineering drawings (PDF/DWG/DXF) or 3D model files (STEP/IGES/SLDPRT/X_T, etc.). The drawings/models must include: Detailed dimensioning and tolerance requirements. Specified material grades. Surface treatment requirements (type, color, thickness, etc.). Quantity. Any special requirements (such as special testing, packaging, etc.). The more accurate and detailed the information provided, the smoother and more efficient the quote and production process will be.

Q: Will the parts be burred after machining? How are they handled?

A: Burrs may be generated during CNC machining. We have a rigorous deburring process, utilizing methods such as manual deburring, vibration grinding, and magnetic polishing to ensure smooth edges on parts delivered to you, meeting the drawing requirements, ensuring safe use and smooth assembly.