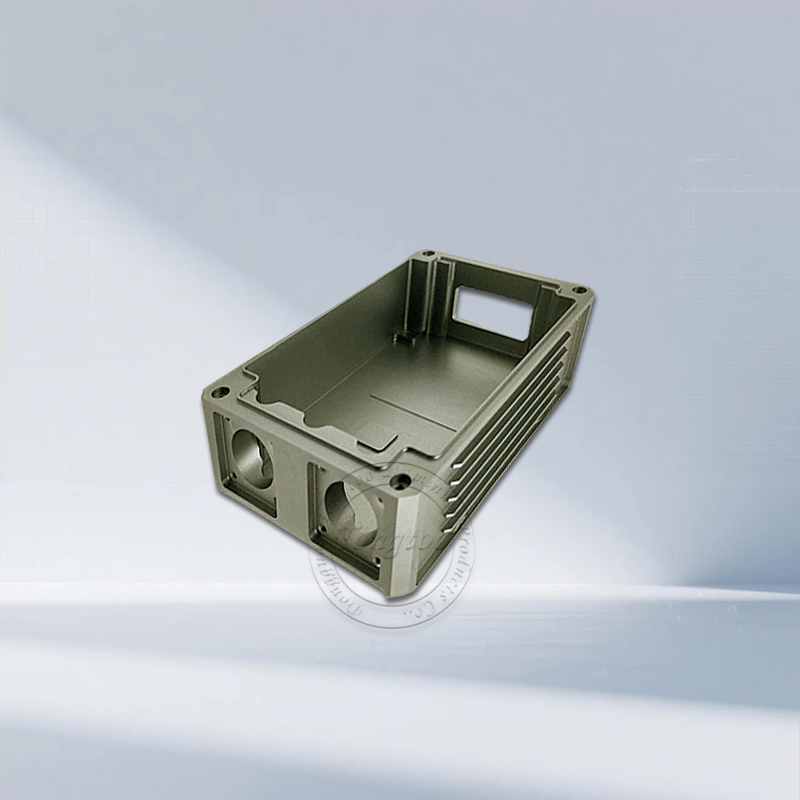

CNC Milling Machining

Tongtoo Aluminum Products Co., Ltd. specializes in providing high-quality, high-precision customized CNC machining services for 7075 aluminum alloy parts. We utilize premium aluminum alloys (such as 6061-T6, 7075-T6, and 5052), utilize advanced CNC machining centers, and employ rigorous quality control procedures. We boast 16 years of experience verifying over 2,000 custom parts. Our German and Japanese five-axis milling clusters guarantee a full-process deformation of less than 0.008mm. Our 48-hour rapid prototyping process provides a complete solution.

Product Description

Product Introduction

Tongtoo Aluminum Products Co., Ltd. specializes in providing high-quality, high-precision customized CNC machining services for 7075 aluminum alloy parts. We utilize premium aluminum alloys (such as 6061-T6, 7075-T6, and 5052), utilize advanced CNC machining centers, and employ rigorous quality control procedures. We boast 16 years of experience verifying over 2,000 custom parts. Our German and Japanese five-axis milling clusters guarantee a full-process deformation of less than 0.008mm. Our 48-hour rapid prototyping process provides a complete solution.

Product Parameters

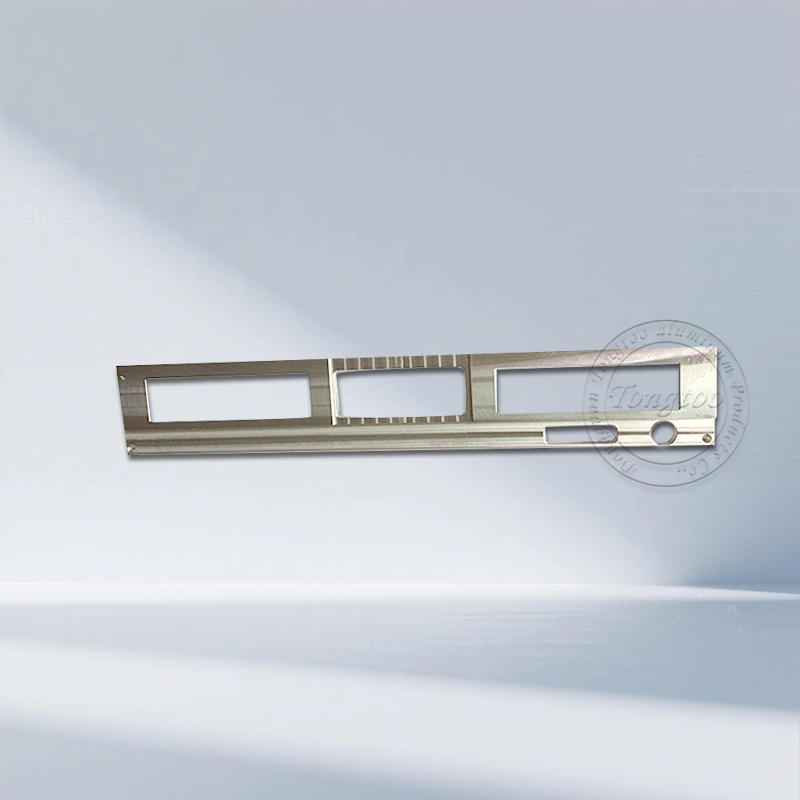

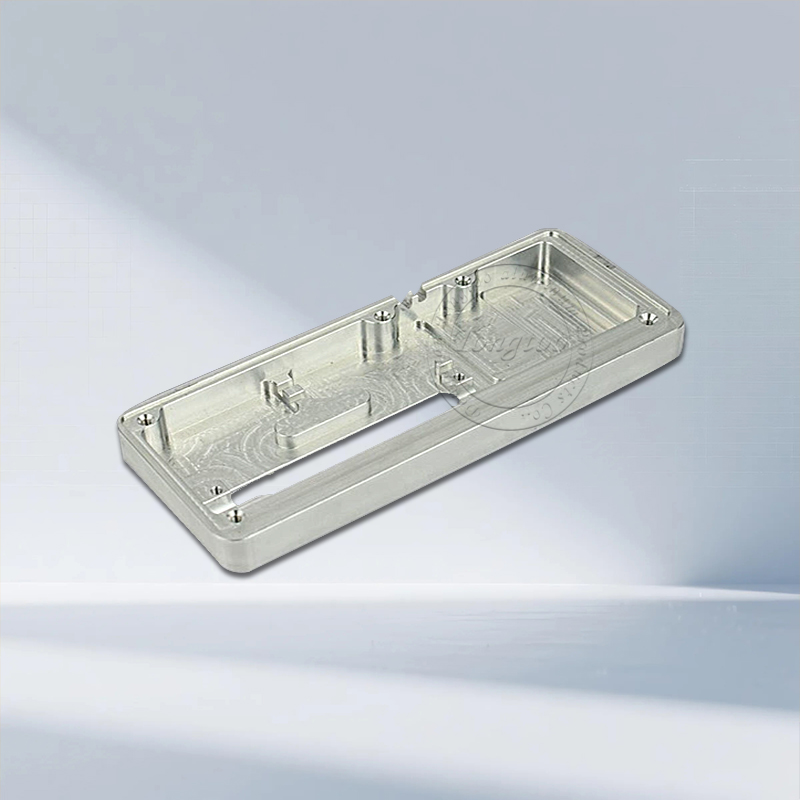

Product Name: CNC Milling

Material: Aluminum Alloy/Titanium Alloy/Stainless Steel

Processing: Die Extrusion/CNC Machining/Milling/Stamping/Die Casting

Surface Treatment: Anodizing/Hard Anodizing/Powder Coating/Laser Engraving

Product Features: Customizable cutouts, dimensions, and logos are supported.

Product Features Applications

A revolutionary breakthrough in traditional milling processes

Thermal displacement compensation technology

Real-time machine temperature compensation system eliminates precision drift caused by continuous machining

300% improvement in precision stability compared to conventional processes (measured data)

Multi-material adaptive milling solution

Carbide: Direct milling of materials below HRC55 (tungsten steel/high-speed steel)

Specialty aluminum: Deformation-free milling of 7075 ultra-hard aluminum

Composite materials: One-step molding of carbon fiber sheet + metal inserts

Unique integrated surface treatment technology

Achieve a Ra 0.1μm mirror finish directly after milling (eliminating the polishing process)

Electrolytic mark-free milling of titanium alloy medical components (compliant with ISO13485 standards)

Applications

Consumer electronics: Mobile phone/tablet midframes and structural components, laptop casings, camera components, audio components, smart wearable device brackets, and radiators.

Automotive: Engine peripheral parts (brackets, housings), sensor housings, chassis components, new energy vehicle battery pack structural components/end plates, charging cable components, and interior trim. Aerospace: (Requires compliance with stricter standards) UAV frames and components, model aircraft parts, aircraft interiors, small satellite structural components (prototypes or non-critical parts), and test fixtures.

Industrial Automation: Robot joints and arms, precision instrument brackets and housings, sensor bases, fixtures, guide rails, cylinder components, and connectors.

Optical and Medical Equipment: Lens barrels, lens mounts, laser housings, medical device housings, brackets, and handles (biocompatibility certification required).

Communications Equipment: 5G base station antenna covers, filter housings, RF device housings, and heat sinks.

Photographic Equipment: Gimbal components, camera grips, lens accessories, and lighting brackets.

Models and Sports Equipment: Bicycle parts (brake handles, pivot points), model aircraft parts, and high-end sports equipment accessories.

Product Details

Intelligent Milling Production Line Configuration (Real Data Support)

Equipment Type

Technical Highlights

Processing Capacity

DMG Five-Axis Nanoscale Grating Closed-Loop Control

Minimum R-Angle 0.05mm

Mazak Milling and Turning Machine

High-Speed Feed of 42m/min

Depth-to-Diameter Ratio of 18:1

Deep Cavity

Brother High-Speed Milling Machine

Axis Speed of 30,000rpm

Maintains 0.15mm Thickness on Thin-Walled Parts

Industry Pain Point Solutions

Customer Needs

Pain Points of Conventional Solutions

Our Innovative Solutions

UAV 7075 Frame Weight Reduction of 30%

Insufficient Rigidity Causes Vibration

Topology Optimization + Residual Stress Reduction Process

Semiconductor Equipment Vacuum Chamber

Welding Deflection Exceeds 0.2mm

Integral Milling Replaces Welding

Product Qualification

Environmental Certifications:

RoHS Certification (Lead-Free, Cadmium-Free, and Other Hazardous Substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production Process Quality Control)

Testing Equipment: Zeiss 3D Scanner (0.8μm Accuracy)

Delivery, Shipping, and Serving

|

|

|

As a professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive customized services tailored to customer needs.

Standard Packaging: Copy Paper + Carton

Custom Packaging: Blister Tray/EPE Foam + Wooden Box

FAQ

Q: What is the achievable accuracy of CNC machining?

A: Standard machining accuracy typically reaches ±0.05mm. For more demanding features, we can achieve ±0.01mm or even higher accuracy through precision equipment and process control. The actual achievable accuracy depends on the specific part structure, size, feature complexity, and the equipment and process used. We will discuss tolerance requirements in detail with you before quoting.

Q: What is the minimum order quantity for a small trial run?

A: Minimum order quantity is 1 piece. Prototype delivery is within 5-15 days, and iterative modifications are supported. For batches of up to 1,000 pieces, unit cost reduction is 30%+.

Q: How long does it take from order placement to delivery? A: Production lead times depend on part complexity, quantity, and current order schedules.

Simple parts/small batch prototyping: Typically approximately 3-7 business days.

Complex parts/medium batches: May take 1-3 weeks.

Large-volume production: This will be assessed based on specific production capacity, typically 2-6 weeks or longer. We will promptly review and provide you with an accurate lead time upon receipt of the drawings or 3D models.

Q: What documents do I need for a quote and production?

A: Please provide clear, complete 2D engineering drawings (PDF/DWG/DXF) or 3D model files (STEP/IGES/SLDPRT/X_T, etc.).

Drawings/models must include:

Detailed dimensioning and tolerance requirements.

Specified material grade.

Surface finish requirements (type, color, thickness, etc.).

Quantity.

Other special requirements (such as special testing, packaging, etc.).

The more accurate and detailed the information provided, the smoother and more efficient the quote and production process.

Q: Will the parts have burrs after machining? How are they handled?

A: Burrs may form during CNC machining. We have a rigorous deburring process, utilizing methods such as manual deburring, vibration grinding, and magnetic polishing to ensure smooth edges and conformance to the drawing requirements, ensuring safe use and smooth assembly.