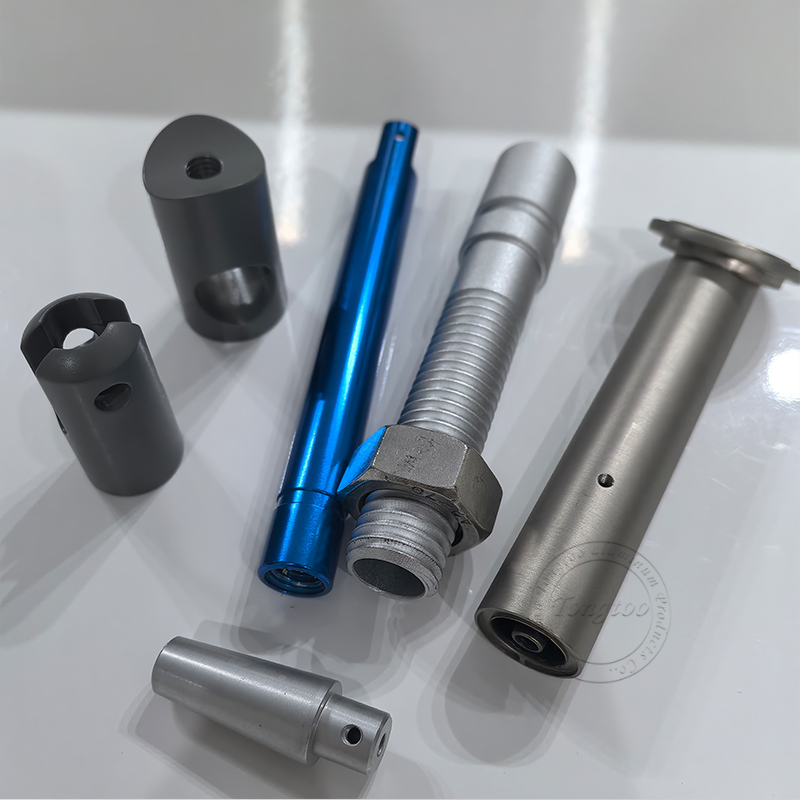

CNC Turned Shaft Components

Dongguan Tongtoo Precision specializes in CNC turning of shaft parts, specializing in precision lathe machining of materials such as stainless steel, aluminum alloy, and copper. We support services ranging from rapid prototyping to mass production, serving the automotive, automation, and medical industries. Get an instant online quote.

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. is a professional enterprise specializing in CNC precision machining, injection molding, mold development, and metal manufacturing of aluminum alloys. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have imported equipment from Germany, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. We focus on exquisite craftsmanship, rapid response, and comprehensive quality inspection to provide customized ODM/OEM solutions for global clients, striving to become a trusted strategic partner in the international industrial manufacturing field.

Product Introduction

Dongguan Tongtoo Precision specializes in CNC turning of shaft parts, specializing in precision lathe machining of materials such as stainless steel, aluminum alloy, and copper. We support services ranging from rapid prototyping to mass production, serving the automotive, automation, and medical industries. Get an instant online quote.

Shaft parts are core components of mechanical equipment, and their accuracy directly impacts the performance of the entire transmission system. As a leading precision machining company, we specialize in CNC turning of various shaft parts. Leveraging advanced CNC lathes (including Swiss and tool-feeding machines), strict quality control systems, and extensive experience in material processing, we ensure that every product we deliver features exceptional dimensional accuracy, geometric tolerances, and surface finish.

CNC turning of shaft parts is a precision manufacturing process that uses computer numerical control technology to rotate the workpiece while simultaneously cutting with a fixed tool to create rotationally symmetrical parts. It is ideal for producing shafts, pins, sleeves, bushings, lead screws, and other parts. Our services cover the entire process, from prototyping to mass production. Whether it's a simple straight shaft or a stepped shaft with complex threads, grooves, or tapers, we achieve efficient and economical production through optimized machining processes and professional CAM programming. We are proficient in the turning characteristics of a wide range of materials, including stainless steel 303/304, aluminum alloy 6061/7075, carbon steel, brass, and engineering plastics, enabling us to meet the strength, hardness, and corrosion resistance requirements of diverse applications.

Product Features and Applications

1. Highest Dimensional Accuracy and Consistency

Precision Control: Our CNC turning processes achieve tight dimensional tolerances, with precision turning tolerances typically maintained within ±0.01 mm, ensuring high consistency in mass-produced parts.

Excellent Geometric Performance: We guarantee excellent concentricity, cylindricity, and straightness, which are critical for high-speed rotating shaft parts.

2. Powerful Complex Feature Machining Capabilities

Combined Machining: We can complete the machining of multiple features, including external diameters, internal bores, end faces, precision threads (metric/imperial), undercuts, oil grooves, and more, in a single clamping operation, minimizing secondary clamping errors. Mill-Turn: For shaft parts with asymmetrical features such as keyways, radial holes, and flattened parts, our mill-turn machining centers can complete all operations on a single machine, significantly improving precision and efficiency.

3. Excellent Surface Finish

Optimized Surface Quality: By fine-tuning cutting parameters and tool paths, excellent surface finishes can be achieved directly, with turned surface roughness reaching Ra 0.8 μm or higher, meeting the requirements of most applications.

Reduced Post-Processing: Excellent machined surfaces can reduce or eliminate subsequent grinding and polishing processes, shortening lead times and reducing costs.

4. Flexible Production Model and High Cost-Effectiveness

Support for Small-Batch Trial Production: We support small-batch processing to help you validate your design at a lower cost.

Advantages of Scaled Production: For large-volume orders, we achieve significant economies of scale through optimized processes and automated production, offering highly competitive pricing.

Fast Delivery: Our comprehensive supply chain and efficient production scheduling ensure fast order delivery.

Applications

Our shaft turning services are widely used in the following applications:

Automotive: drive shafts, pins, valve cores, sensor housings, etc.

Industrial automation and robotics: lead screws, couplings, guide shafts, and robot joint shafts.

Medical equipment: micro shafts, surgical instrument handles, and medical pump components (using materials that meet medical standards).

Hydraulic and pneumatic systems: piston rods, valve stems, and cylinder barrels.

General machinery: various drive shafts, spindles, gear shafts, and fasteners.

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production Process Quality Control)

Testing Equipment: Zeiss 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive, customized services tailored to customer needs.

Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/PEF + wooden box

Global Export Experience: Familiar with international packaging and shipping standards, we consistently supply our products to global markets including Europe, America, Japan, and South Korea.

FAQ

Q1: What is the achievable precision of your turning operations?

A: For conventional precision turning, we can consistently guarantee a dimensional tolerance of ±0.01mm and a surface roughness of Ra 1.6μm. For parts with more stringent requirements, we can achieve tolerances up to ±0.005mm and surface finishes as fine as Ra 0.8μm through process optimization. The specific accuracy depends on part size, structure, and material.

Q2: What type of lathes do you use? What is the difference between a Swiss-type lathe and a CNC-type lathe?

A: We have both high-performance CNC-type lathes and CNC-type lathes.

CNC-type lathes are suitable for machining large-diameter, short-length shaft parts and offer a high cost-effective solution.

CNC-type lathes are particularly well-suited for machining small-diameter, precision shaft parts with large aspect ratios and complex shapes. They can complete multiple steps in a single setup, offering exceptional accuracy and efficiency. Our engineers will recommend the most suitable equipment based on your part drawings.

Q3: How can I obtain a machining quote for shaft parts? What do I need to provide?

A: Please provide detailed 2D drawings (PDF/DWG format is preferred, with clear dimensions, tolerances, material, heat treatment, and surface finish requirements) and/or 3D models (e.g., STEP or IGS formats). This is the foundation for our Design for Manufacturability (DFM) analysis and accurate quotes.

Q4: What post-production surface treatments do you offer?

A: We offer a wide range of post-production options, including anodizing (aluminum), hard chrome plating, blackening, passivation (stainless steel), heat treatment (quenching, tempering), and sandblasting, to meet diverse requirements for wear resistance, corrosion resistance, and aesthetics.

Q5: Is there a minimum order quantity (MOQ)?

A: We offer flexible ordering services, supporting both single-piece prototypes and large-volume production. We understand the needs of small-volume orders for R&D and trial production; for large-volume orders, we can offer more favorable pricing.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), CNC lathes, milling machines, lathes, grinders, etc.; and over a dozen inspection equipment (inspection accuracy up to 0.001 MM), achieving internationally advanced machining capabilities. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts supporting industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with superior precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.