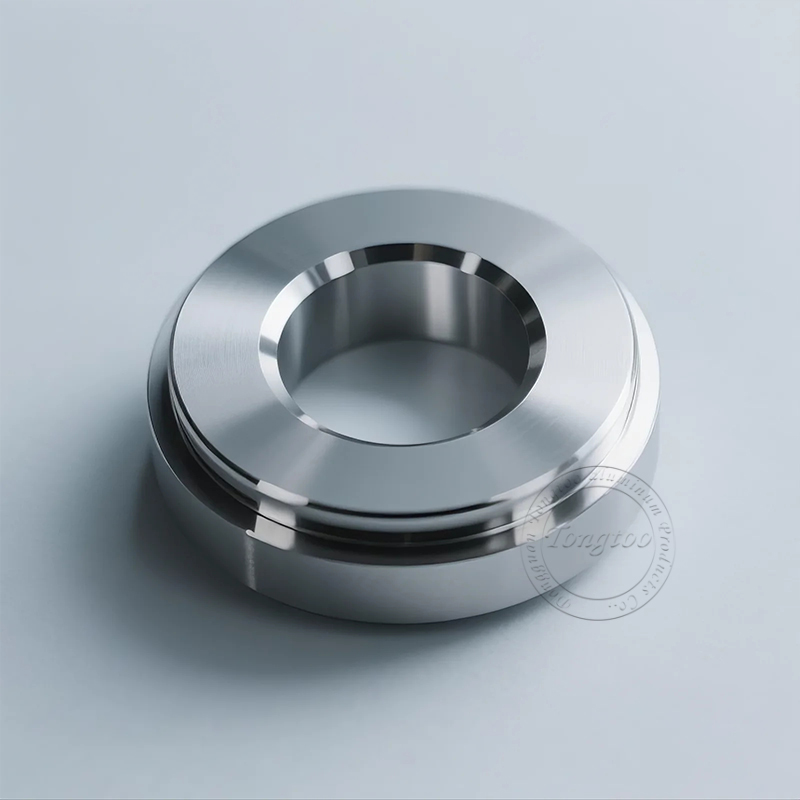

CNC Machining for External Cylindrical Parts

External turning is a precision machining technology that uses CNC lathes to perform rotary cutting on materials such as metals and plastics. It is widely used in the manufacture of rotating parts such as shafts, threads, and sleeves. Its high precision, high efficiency, and strong adaptability have made it an indispensable process in modern manufacturing, particularly for the production of key components in the automotive, aerospace, and medical device industries.

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. is a professional enterprise specializing in CNC precision machining, injection molding, mold development, and metal manufacturing of aluminum alloys. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have imported equipment from Germany, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. We focus on exquisite craftsmanship, rapid response, and comprehensive quality inspection to provide customized ODM/OEM solutions for global clients, striving to become a trusted strategic partner in the international industrial manufacturing field.

Product Introduction

External turning is a precision machining technology that uses CNC lathes to perform rotary cutting on materials such as metals and plastics. It is widely used in the manufacture of rotating parts such as shafts, threads, and sleeves. Its high precision, high efficiency, and strong adaptability have made it an indispensable process in modern manufacturing, particularly for the production of key components in the automotive, aerospace, and medical device industries.

External Turning Product Description:

Processing Principle

The workpiece rotates under the spindle's drive, while the turning tool feeds axially or radially, removing excess material to create precise external cylindrical, stepped, and tapered surfaces. It supports a variety of operations, including turning, boring, grooving, and threading.

Technical Parameters

Precision Grade: Dimensional tolerances up to ±0.01mm, surface roughness Ra ≤0.8μm.

Applicable Materials: Carbon steel, stainless steel, aluminum alloy, titanium alloy, and engineering plastics.

Maximum Processing Diameter: φ10mm to φ500mm, depending on machine specifications. Equipment Types: Economical general lathes, high-precision CNC lathes, and multi-axis turning-milling centers.

Product Features and Applications

Ultra-high-precision CNC system closed-loop control compensates for tool wear, ensures batch-to-batch consistency, and meets the demands of precision part machining.

Efficient Production: Synchronous operation of multiple turrets shortens cycle times, making it suitable for high-volume turning orders.

Flexible Adaptability: The rapid tool change system supports machining complex structures such as thread turning and curved contours.

Cost Optimization: Reduces manual intervention, lowers scrap rates, and helps companies control component manufacturing costs.

Wide Material Compatibility: From aluminum alloys to high-temperature alloys, high-quality machining can be achieved through optimized cutting parameters.

Applications:

Our external turning services are widely used in various industries:

Automotive: Turning automotive parts such as engine shafts, brake discs, and transmission components.

Aerospace: High-temperature alloy components such as landing gear pins and turbine shafts meet the requirements of turning high-strength materials.

Medical Devices: Precision turning of stainless steel for surgical instruments, implants, and other medical applications. Industrial Equipment

Customized machined parts such as hydraulic rods, bearing seats, and lead screws.

Electronic Equipment

Small precision turned parts such as camera metal rings and heat sinks.

Product Qualification

Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (Production Process Quality Control)

Testing Equipment: Zeiss 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive, customized services tailored to customer needs.

|

|

|

Standard Packaging: Copy paper + carton

Customized Packaging: Blister tray/PEF + wooden box

Global Export Experience: Familiar with international packaging and shipping standards, we consistently supply products to global markets including Europe, America, Japan, and South Korea.

FAQ

Q1: Can we process difficult-to-cut materials such as stainless steel?

Yes. Specialized tooling and cooling technology address the issues of hardening and tool sticking during stainless steel turning.

Q2: What is the minimum order quantity and lead time?

We support small-batch trial runs (minimum 50 pieces). Large-volume orders have a lead time of 7-15 days, depending on the complexity of the drawing.

Q3: How do you ensure the rust resistance of parts?

We offer metal surface treatment services such as oxidation, electroplating, and passivation to extend the life of parts.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), CNC lathes, milling machines, lathes, grinders, etc.; and over a dozen inspection equipment (inspection accuracy up to 0.001 MM), achieving internationally advanced machining capabilities. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts supporting industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with superior precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.