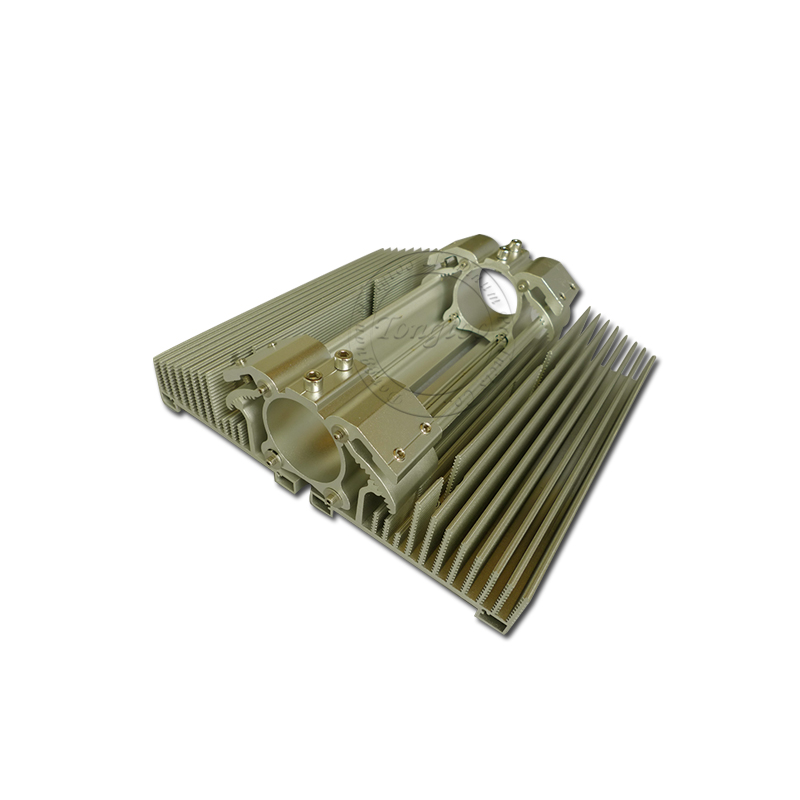

Aluminum Alloy Solar Shell CNC Precision Machining

The product achieves a perfect balance between strength and weight through thin-wall processing technology (minimum wall thickness 1.2mm), adapts to harsh outdoor environments, and meets the dual needs of the new energy industry for structural reliability and rapid mass production.

Product Description

DongGuan TongToo Aluminum Products Co., Ltd. is a company specializing in aluminum alloy CNC precision machining, injection molding, mold development, and metal parts manufacturing. It has obtained ISO 9001 international certification and strictly implements the 6S management system. With the introduction of German imported equipment, its products are exported to more than 20 countries including Europe, America, and Southeast Asia, with an average annual delivery volume of more than 5 million pieces. With exquisite craftsmanship, fast response, and full-process quality inspection as the core, we provide customized ODM/OEM solutions for global customers and strive to become a trusted strategic partner in the field of international industrial manufacturing.

Product Introduction

We are deeply engaged in the field of aluminum alloy precision CNC processing and die-casting processing, focusing on the customized production of solar equipment housings, using aviation-grade aluminum alloys such as 6061-T6, 6082-T6, and ADC12 to provide high-precision, lightweight, and corrosion-resistant one-piece housing solutions for photovoltaic junction boxes, inverters, energy storage battery boxes, etc. The product achieves a perfect balance between strength and weight through thin-wall processing technology (minimum wall thickness 1.2mm), adapts to harsh outdoor environments, and meets the dual needs of the new energy industry for structural reliability and rapid mass production.

Product Parameter

Product Name Aluminum Alloy Solar Street Light Shell

Product Material 6063/ADC12

Processing Technology: Precision Die Casting/CNC Processing

Surface Treatment: Hard Anodizing (HV≥300), Sandblasting Matte, Conductive Oxidation (Anodizing/Fluorocarbon Spraying Optional)

Product Features: Photovoltaic MC4 Connector, RS485 Communication Port, Cooling Fan Slot

Product Feature And Application

High Efficiency and Low Cost: Single-mode life of 200,000 times, cost is 60% lower than CNC (orders of more than 5,000 pieces).

Five-axis CNC linkage processing of complex curved surfaces and special-shaped structures, one-time clamping to complete polyhedron processing, eliminating joint hazards, and improving the overall strength of the shell

Topological optimization and weight reduction

Through finite element analysis (FEA) to optimize material distribution, reduce weight by 30% while maintaining a compressive strength of more than 150MPa, reducing transportation and installation costs

Integrated heat dissipation solution

CNC milling precision forming heat dissipation channel + anodizing surface treatment, heat conduction efficiency increased by 40%, ensuring equipment stability in high temperature environment

Anti-corrosion

Hard anodized film thickness of 25-50um, salt test 2000 hours without corrosion, suitable for coastal, sand and other high-corrosion scenes

Quick response delivery

From 3D drawings to first piece verification in 7 days, supporting small batch trial production (1 piece minimum order) and large batch orders.

Application scenarios

Photovoltaic junction box shell: IP68 protection + UV protection design, suitable for double glass components and BIPV building integration.

Outdoor inverter shell: five-axis processing heat dissipation duct, compatible with 100kW high-power heat dissipation requirements.

Energy storage battery box: thin-walled and lightweight + earthquake-resistant structure, meeting the requirements of container-type energy storage system deployment.

Solar tracking bracket: high-precision bearing installation holes to ensure the rotation stability of the tracking system.

Off-grid controller housing: CNC milling waterproof groove + silicone seal, adapted to the humid environment of tropical rainforests.

Product Details

Precision CNC one-piece molding, tolerance controlled at ±0.01mm, ensuring accurate hole positions and tight fit.

The aluminum alloy housing has the advantage of natural thermal conductivity and excellent heat dissipation performance, effectively reducing the internal operating temperature and extending the product life.

With nano-level anti-UV surface treatment anodizing, it is corrosion-resistant and non-fading, and provides a variety of colors such as silver, black, etc., which is beautiful and wear-resistant.

Product Qualification

Environmental certification:

RoHS certification (lead-free, cadmium-free and other hazardous substances)

REACH (EU chemical safety standards)

Quality management system:

ISO 9001:2016/ISO 9001:2015 (production process quality control)

Deliver, Shipping And Serving

Professional ODM & OEM manufacturer, with more than 20 years of precision machining experience, customer-oriented, providing a full range of customized services.

|

|

|

FAQ

Q: How to choose CNC or die-casting process?

A: Decision based on order quantity and structural complexity:

CNC: small batch (<500 pieces), complex structure (deep cavity/thin wall), high mechanical performance requirements (7075-T6).

Die casting: large batch (>3000 pieces), regular structure, cost-sensitive projects.

Q: How to ensure that thin-wall processing does not deform?

A: Adopting multi-process stress release technology and high-speed low-cutting force processing parameters, combined with vacuum fixture fixation, ensures that the flatness of thin-walled parts is ≤0.1mm/m².

Q: Can batch processing consistency be achieved?

A: Equipped with an online detection system (Renishaw probe), real-time compensation for tool wear, and batch workpiece size fluctuations are controlled within ±0.03mm.

Q: Does it support EMC electromagnetic shielding design?

A: Yes! Through CNC machining of continuous conductive surface + nickel plating, the shell shielding effectiveness reaches 60dB (10MHz-1GHz).

Q: Is the customization cost much higher than traditional processes?

A: CNC machining saves mold opening costs, and the comprehensive cost of small batch orders is lower. In addition, aluminum alloy is 100% recyclable, which is more economical for long-term use.

Q: What is the production cycle and minimum order quantity?

A: 1 piece minimum order, samples are delivered in 10-15 days, and batch orders are completed in 20-30 days.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of production equipment, including German Hammer five-axis CNC machining center (machining accuracy up to 0.002 MM), turning and milling composite CNC lathe, CNC lathe, milling machine, lathe, grinder, etc.; as well as more than a dozen various inspection equipment (including German Cai's three-dimensional, with inspection accuracy up to 0.001MM), and the machining capacity has reached the international advanced level. The Tengtu team has the most professional mold design and CNC machining knowledge. We will work closely with you during the prototyping, production, assembly, inspection, packaging and final delivery process to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts that support industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation and manufacture and assemble important components with excellent precision, strict tolerances and high-quality materials. Over the past 11 years, Tengtu has established a high reputation for efficiency, quality, reliability and on-time delivery.