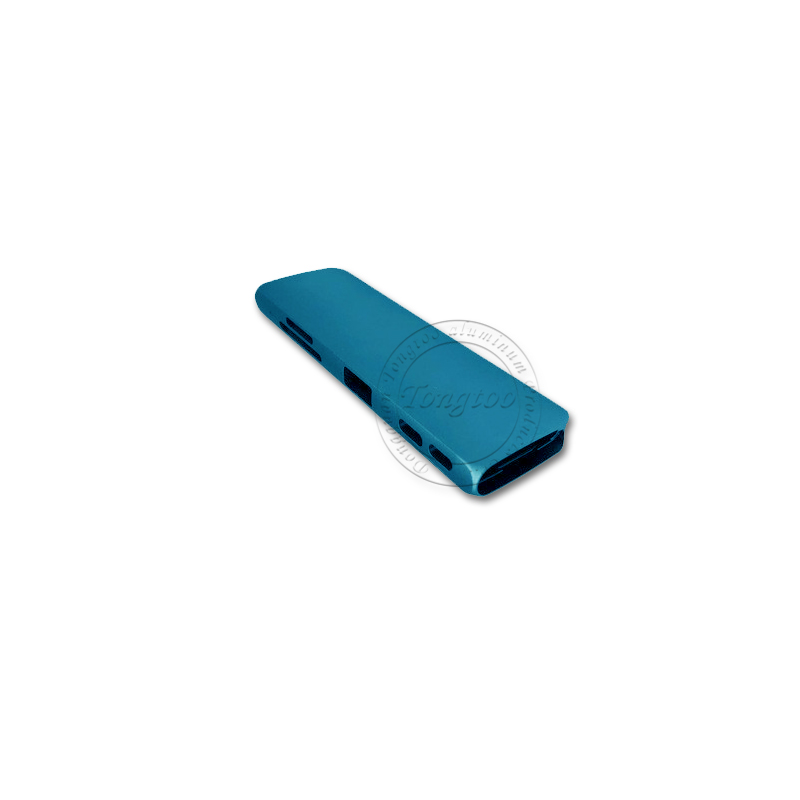

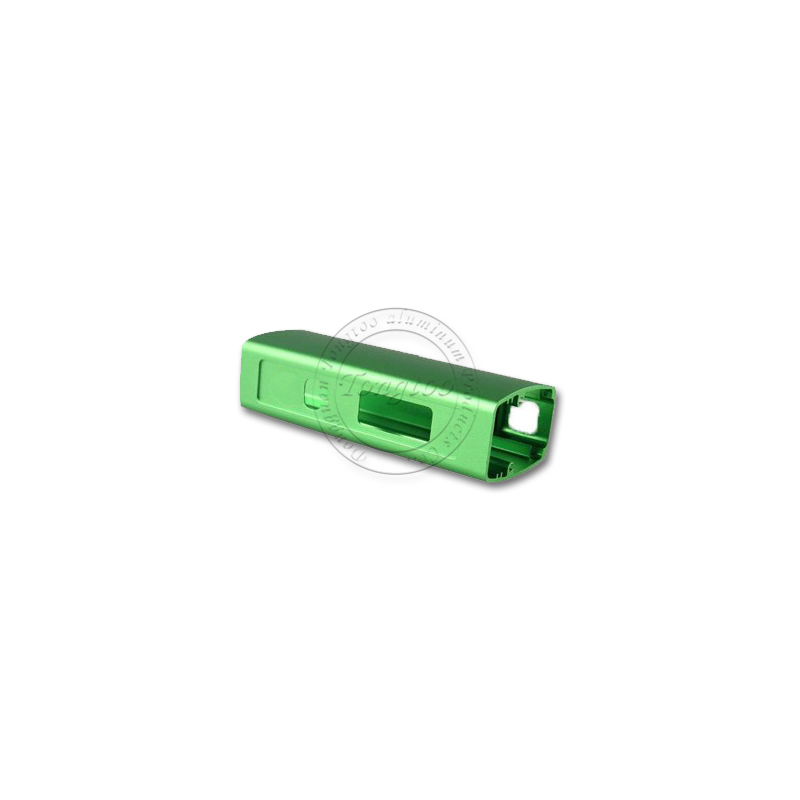

Efficiently Dissipating Heat Aluminum Alloy Docking Station Shell

We provide professional aluminum alloy docking station shell CNC processing services, using aviation-grade aluminum alloy (6061-T6/7075-T6) and CNC numerical control technology to create high-precision, strong heat dissipation, one-piece metal shell solutions for Type-C and Thunderbolt interface docking stations.

Product Description

DongGuan TongToo Aluminum Products Co., Ltd. is a company specializing in aluminum alloy CNC precision machining, injection molding, mold development, and metal parts manufacturing. It has obtained ISO 9001 international certification and strictly implements the 6S management system. With the introduction of German imported equipment, its products are exported to more than 20 countries including Europe, America, and Southeast Asia, with an average annual delivery volume of more than 5 million pieces. With exquisite craftsmanship, fast response, and full-process quality inspection as the core, we provide customized ODM/OEM solutions for global customers and strive to become a trusted strategic partner in the field of international industrial manufacturing.

Product Introduction

We provide professional aluminum alloy docking station shell CNC processing services, using aviation-grade aluminum alloy (6061-T6/7075-T6) and CNC numerical control technology to create high-precision, strong heat dissipation, one-piece metal shell solutions for Type-C and Thunderbolt interface docking stations. The product is compatible with multiple interface layouts such as USB, HDMI, and network ports, supports personalized surface treatment and brand customization, and meets the dual needs of stability and high-end texture in business office, e-sports equipment, industrial control and other fields.

Product Parameter

Product Name Aluminum Alloy Docking Station Shell

Product Material Aluminum Alloy

Processing Technology Precision CNC Processing

Surface Treatment Anodizing

Customized Service Supports drawing customization, sample reproduction, and special function requirements development

Product Feature And Application

Precision Interface Adaptation

CNC precision processes multiple types of interface holes, with a tolerance control of ±0.01mm, ensuring smooth and unbiased plugging and unplugging of interfaces such as USB and HDMI.

Intelligent heat dissipation system

Aluminum alloy body + honeycomb heat dissipation hole design quickly exports internal heat of the docking station, avoids performance degradation under high load, and ensures data transmission stability.

Industrial-grade durability

Aviation aluminum is resistant to pressure and drop, and the surface anodized layer is scratch-resistant and anti-fingerprint, which is suitable for frequent plugging and unplugging and mobile office scenes.

Minimalist aesthetic design

Support matte, glossy, gradient laser engraving and other processes to create business, e-sports, geek styles and enhance product added value.

One-stop flexible customization

From drawing design, proofing to mass production, fast delivery in 10-15 days, supporting small batch trial production (1 piece minimum order) and large-scale orders.

Application scenarios

Business office docking station: light and portable, suitable for MacBook, Surface and other devices, improving multi-screen collaboration efficiency.

E-sports peripherals: enhanced heat dissipation design, support 4K@120Hz video output, meet high-bandwidth data transmission requirements.

Industrial control terminal: anti-electromagnetic interference, compatible with RS232, GPIO and other industrial interface customization.

Outdoor mobile workstation: IP65 protection + shockproof design, adapt to equipment expansion needs in harsh environments.

Brand customized peripherals: corporate LOGO laser engraving, as a high-end business gift or promotional item.

Product Details

Material: 6061 aluminum alloy, 5052 aluminum alloy (optional anodizing, sandblasting and other processes)

Thickness range 0.8mm~5mm (customized according to heat dissipation requirements)

Processing accuracy ±0.05mm (key interface position accuracy up to ±0.02mm)

Surface treatment Anodizing (black/silver/gray), sandblasting, brushing, laser engraving brand LOGO

Adaptive power 5W~50W (compatible with Qi standard and other wireless charging protocols)

Heat dissipation design Built-in heat conduction groove/heat dissipation hole structure to reduce charging temperature rise

Anti-interference design Optimize electromagnetic shielding to ensure charging stability

Product Qualification

RoHS certification (lead-free, cadmium-free and other hazardous substances)

REACH (EU chemical safety standards)

Quality management system:

ISO 9001:2016/ISO 9001:2015 (production process quality control)

Deliver, Shipping And Serving

Factory transportation method: use professional shockproof packaging and logistics cooperation to ensure zero damage to the product during transportation and support global delivery.

Packaging method: Each product uses double-layer protection of copy paper/bubble bag + carton/wooden box to ensure that there are no scratches on the surface, suitable for long-distance transportation.

Professional ODM & OEM manufacturer, with more than 20 years of precision machining experience, customer-oriented, from design, proofing to mass production, follow-up, providing a full range of customized services. 7-15 days proofing cycle, 99% on-time delivery rate for mass production, and 3D drawing design support.

|

|

|

FAQ

Q: Does the aluminum alloy shell affect signal transmission?

A: No! We optimize the opening position and electromagnetic shielding design to ensure stable transmission of wireless signals such as Wi-Fi and Bluetooth.

Q: Can it support the 40Gbps high-speed transmission of the Thunderbolt 4 interface?

A: Support! The shell structure is compatible with the heat dissipation requirements of the Thunderbolt 4 chip, and reserves precise positioning holes for high-speed interfaces.

Q: What design files are required for customization?

A: 3D drawings (STEP/IGES format), interface type and position table, and surface process requirements are required. If there are no drawings, sample reverse modeling can be provided.

Q: Does it support anti-slip foot pad design?

A: Yes! The bottom groove can be CNC machined and silicone/rubber foot pads can be embedded to enhance the stability of the desktop.

Q: How is the minimum order quantity and price calculated?

A: 1 piece can be used for proofing. The unit price is quoted in stages based on material thickness, process complexity, and order quantity, and a transparent cost list is provided.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of production equipment, including German Hammer five-axis CNC machining center (machining accuracy up to 0.002 MM), turning and milling composite CNC lathe, CNC lathe, milling machine, lathe, grinder, etc.; as well as more than a dozen various inspection equipment (including German Cai's three-dimensional, with inspection accuracy up to 0.001MM), and the machining capacity has reached the international advanced level. The Tengtu team has the most professional mold design and CNC machining knowledge. We will work closely with you during the prototyping, production, assembly, inspection, packaging and final delivery process to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts that support industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation and manufacture and assemble important components with excellent precision, strict tolerances and high-quality materials. Over the past 11 years, Tengtu has established a high reputation for efficiency, quality, reliability and on-time delivery.