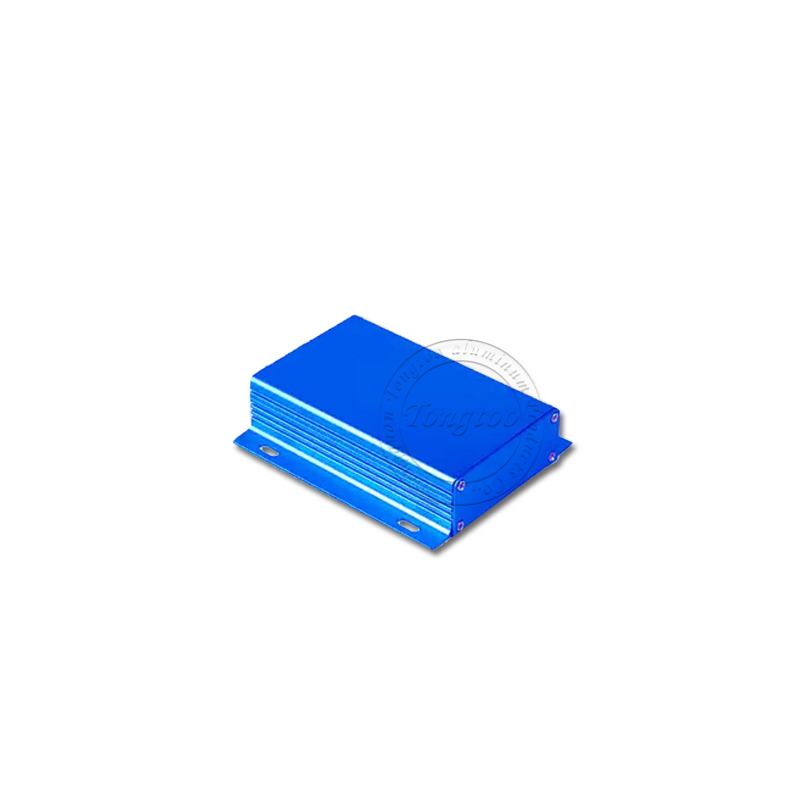

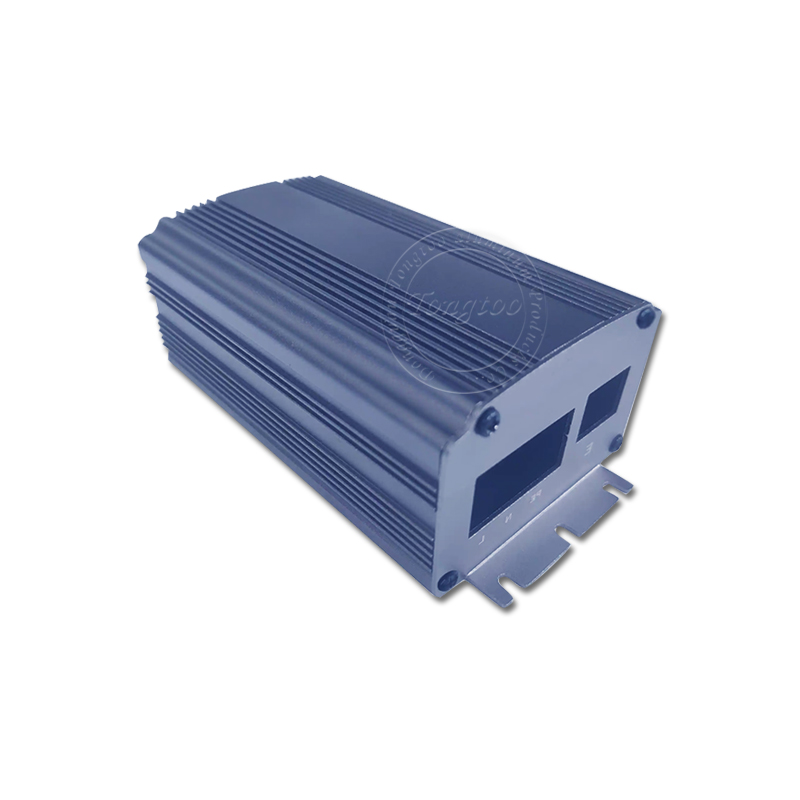

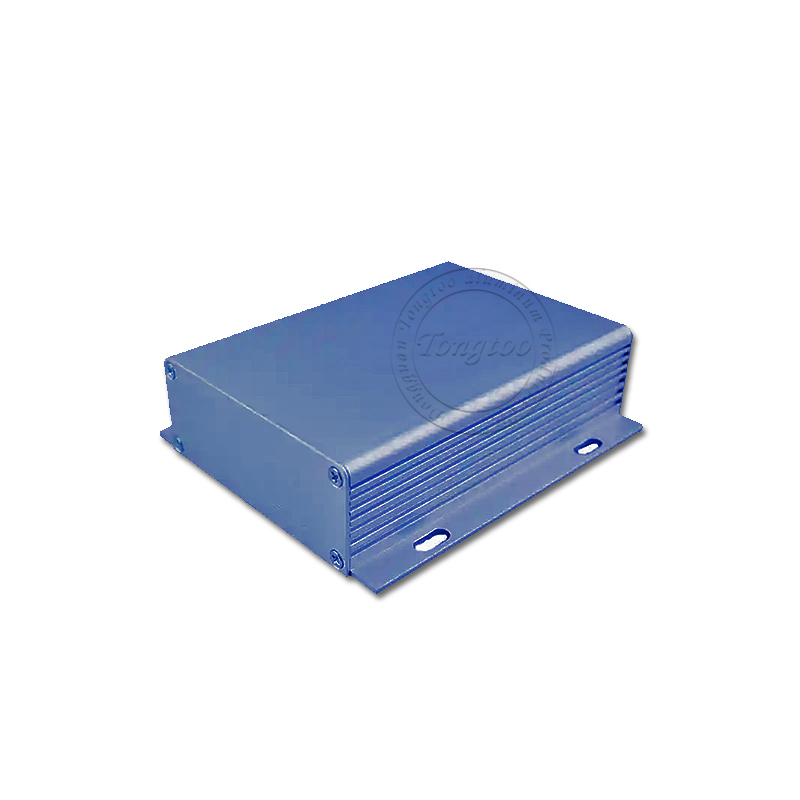

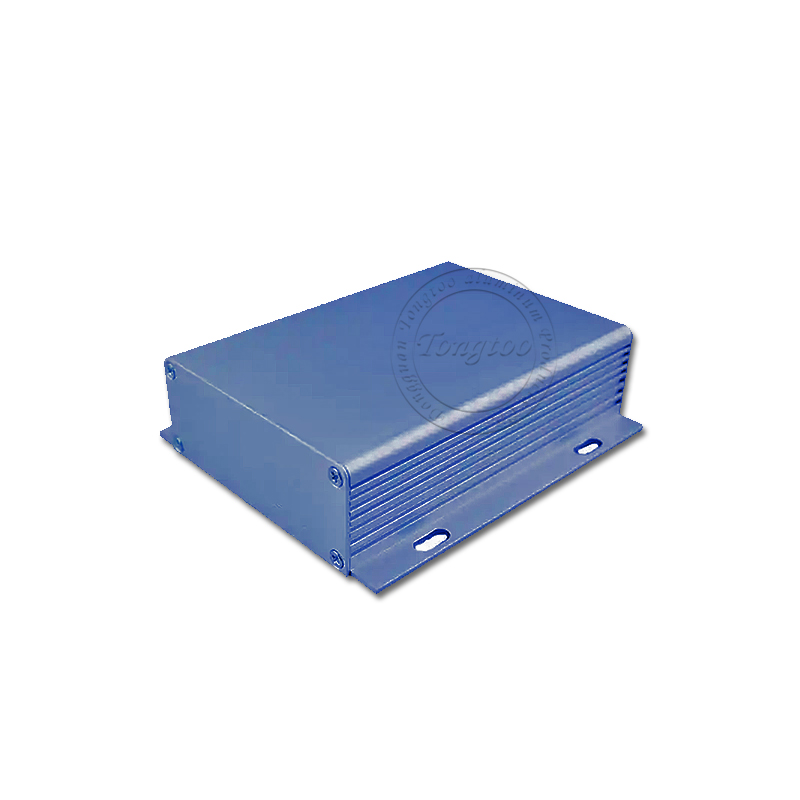

High Precision Extruded Aluminum Alloy Relay Housing

The relay housing is made of aluminum alloy extrusion molding process, and the extrusion die is customized based on customer needs, combined with five-axis CNC precision machining technology.

Product Description

DongGuan TongToo Aluminum Products Co., Ltd. is a company specializing in aluminum alloy CNC precision machining, injection molding, mold development, and metal parts manufacturing. It has obtained ISO 9001 international certification and strictly implements the 6S management system. With the introduction of German imported equipment, its products are exported to more than 20 countries including Europe, America, and Southeast Asia, with an average annual delivery volume of more than 5 million pieces. With exquisite craftsmanship, fast response, and full-process quality inspection as the core, we provide customized ODM/OEM solutions for global customers and strive to become a trusted strategic partner in the field of international industrial manufacturing.

Product Introduction

The relay housing is made of aluminum alloy extrusion molding process, and the extrusion die is customized based on customer needs, combined with five-axis CNC precision machining technology. It is specially designed to provide military-grade protection for medium and high voltage relay modules. It has IP67 sealing (upgradeable to IP69K), 70dB+ EMC shielding and -40℃~150℃ wide temperature range performance, and supports full-process precision customization from extrusion die design → profile mass production → CNC precision milling → hard oxidation, meeting the stringent requirements of new energy vehicles, power equipment and other fields for vibration resistance, efficient heat dissipation and compact installation.

Customized aluminum alloy extrusion profiles are developed through precision molds and manufactured by five-axis CNC machining centers.

Product Parameter

Product Name Aluminum Alloy Relay Housing

Product Material 6063 Aluminum Alloy

Processing Technology: Extrusion Mold + CNC Milling

Surface Treatment: Anodizing/Hard Oxidation/Laser Engraving

Product Features: Modular structure, supports personalized opening, size, and LOGO customization

Product Feature And Application

Process Link Core Technology Industry Value

Extrusion Mold Customized Diversion Mold · Wall Thickness 1.5-5mm Adjustable · Hollow Heat Dissipation Channel Integrated Molding Material Utilization Rate↑35% · Structural Strength↑50%

CNC Finishing Five-axis Linkage Machining Center · Precision Hole Opening (±0.02mm) · Seal Groove Precision Milling Eliminate assembly stress and increase sealing by 2 times

Surface Treatment Hard Anodizing (Film Thickness 20-25μm) · Conductive Oxidation (<0.1Ω) Corrosion Resistance↑60% · EMC shielding effectiveness↑

Application scenarios:

New energy vehicles

Battery management system: high-voltage relay sealed cabin

Onboard charger: DC-DC module shielding shell

Electric drive system: motor controller shell

Electric power

Photovoltaic inverter: DC relay protection box (UV-resistant profile)

Intelligent distribution cabinet: magnetic latching relay shell (anti-electricity theft structure)

Energy storage system: contactor explosion-proof shell

Industrial automation

PLC control cabinet: safety relay module (DIN rail direct installation)

Robot electronic control: joint controller shielding cover (anti-electromagnetic interference)

Rail transit: signal relay box

Product Details

Electromagnetic fortress-level shielding

Fully enclosed metal cavity + reed pad conductive path

CISPR 32 Class B certified (30MHz-1GHz shielding>70dB)

Dynamic environment protection

Vibration-resistant design: passed IEC 60068-2-6 10G vibration test

Salt spray protection: 1000h neutral salt spray test (GB/T 10125)

Chemical corrosion protection: oil/electrolyte corrosion resistance (ISO 9227 compliant)

Product Qualification

Environmental certification:

RoHS certification (lead-free, cadmium-free and other hazardous substances)

REACH (EU chemical safety standards)

Quality management system:

ISO 9001:2016/ISO 9001:2015 (production process quality control)

Deliver, Shipping and Serving

Professional ODM & OEM manufacturer, with more than 20 years of precision processing experience, based on customer needs, providing a full range of customized services.

Standard packaging: copy paper + carton

Customized packaging: blister tray / pearl cotton + wooden box

Packing solution: pearl cotton + carton/wooden box.

|

|

|

FAQ

Q1: What are the cost advantages and disadvantages of extrusion mold opening vs die casting process?

Project Extrusion mold Die casting process

Thermal conductivity Thermal resistance <1.5℃/W (good longitudinal thermal conductivity) Thermal resistance >2.5℃/W

Material utilization 85%+ (no casting and riser loss) 60%-70%

Small batch cost Mold fee as low as ¥8,000 Mold fee ¥30,000+

Applicable scenarios Long strip/hollow structure Complex three-dimensional special-shaped body

Q2: How to ensure the flatness of the sealing surface after CNC processing?

Special fixture: hydraulic expansion fixture (deformation <0.01mm)

Tool strategy:

Rough machining: φ8mm corn milling cutter (allowance 0.3mm)

Fine machining: φ4mm carbide cutter (speed 12000rpm)

Q3: How long does it take to customize an aluminum alloy shell?

A: The customization cycle depends on the complexity of the design, whether mold opening is required (such as extrusion mold/die casting mold), production quantity and surface treatment process. Usually:

CNC prototype proofing: 3-7 working days (providing 3D drawings).

Small batch customization (without mold): 7-15 working days (based on sheet metal processing and CNC).

Extrusion mold development involved: mold making time (usually 2-4 weeks) + production time.

Middle and large batch production: high efficiency after the mold/process is finalized. We provide quick response service and can communicate specific urgent needs.

Q4: What is the minimum order quantity (MOQ) for customization?

A: We understand the needs of customers at different stages (R&D, trial production, mass production). For non-standard customization:

CNC processing/sheet metal bending: usually supports small batch MOQ, even single piece proofing.

Profile box that requires extrusion mold: There will be a minimum order quantity requirement for the first production (to share the mold cost), the specific quantity depends on the complexity and size of the profile section, which can be negotiated. There is no minimum quantity limit for subsequent orders (but the unit price is better for large quantities).

Q5: What do I need to provide to start customization?

A: The more detailed the information you provide, the more accurate and efficient the customization will be. Ideally, please provide:

3D model files (STEP, IGS, X_T and other formats are best).

Clear 2D engineering drawings (marking key dimensions, tolerances, opening requirements, surface treatment, etc.).

Written technical requirements: including but not limited to material requirements, protection level (IPXX), heat dissipation requirements, EMC requirements, internal installation requirements (guide rail/copper column position), lock/hinge type, surface treatment color and process, certification requirements, etc.

If there is only a concept or sketch, our engineering team can provide design support and jointly optimize the solution.

Q6: Can small batch customization (within 100 pieces) be achieved? How to control costs?

A: Flexible production plan:

Within 50 pieces: CNC machining + sheet metal process (free mold opening fee)

100-500 pieces: combined mold solution (reduce mold cost by 30%)

>500 pieces: extrusion mold/die-casting mold optimizes mass production cost

Reduce customization costs through standardized module libraries (such as sealing structure/mounting hole position)

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of production equipment, including German Hammer five-axis CNC machining center (machining accuracy up to 0.002 MM), turning and milling composite CNC lathe, CNC lathe, milling machine, lathe, grinder, etc.; as well as more than a dozen various inspection equipment (including German Cai's three-dimensional, with inspection accuracy up to 0.001MM), and the machining capacity has reached the international advanced level. The Tengtu team has the most professional mold design and CNC machining knowledge. We will work closely with you during the prototyping, production, assembly, inspection, packaging and final delivery process to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts that support industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation and manufacture and assemble important components with excellent precision, strict tolerances and high-quality materials. Over the past 11 years, Tengtu has established a high reputation for efficiency, quality, reliability and on-time delivery.