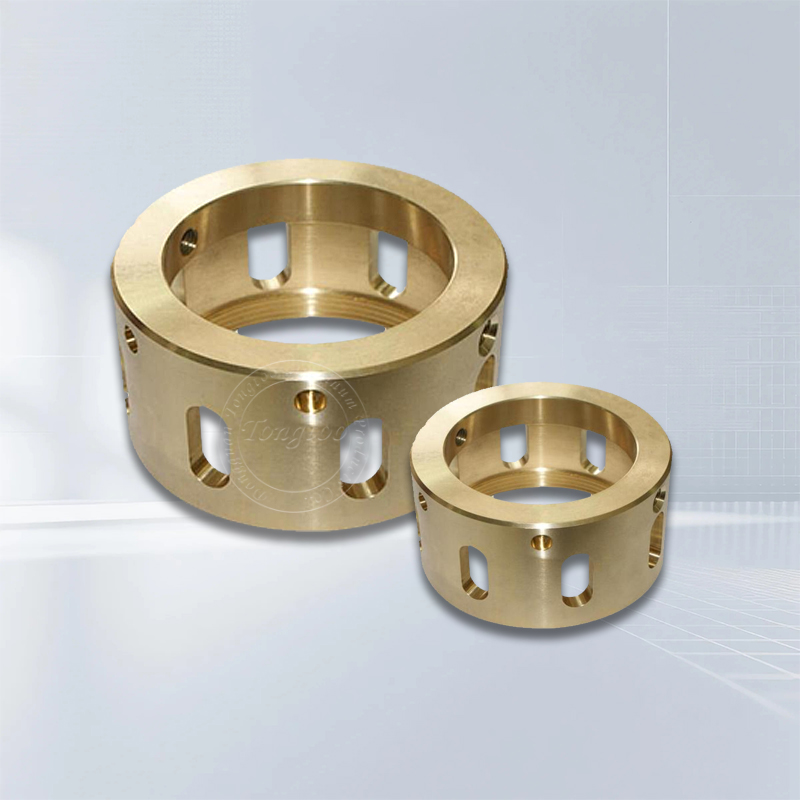

Brass CNC Machined Parts for Industrial Equipment

CNC brass machining utilizes computer numerical control (CNC) technology to precisely mill and turn brass blanks to create complex parts. Brass, due to its excellent mechanical properties, electrical conductivity, and corrosion resistance, is a popular non-ferrous metal processing material in industries such as electronics, bathroom fixtures, and medical devices. We provide a one-stop CNC brass parts solution, from rapid prototyping to mass production.

Product Description

Dongguan Tongtoo Aluminum Products Co., Ltd. is a professional enterprise specializing in CNC precision machining, injection molding, mold development, and metal manufacturing of aluminum alloys. We have obtained ISO 9001 international certification and strictly implement the 6S management system. We have imported equipment from Germany, and our products are exported to more than 20 countries in Europe, America, and Southeast Asia, with an average annual delivery volume exceeding 5 million pieces. We focus on exquisite craftsmanship, rapid response, and comprehensive quality inspection to provide customized ODM/OEM solutions for global clients, striving to become a trusted strategic partner in the international industrial manufacturing field.

Product Introduction

CNC brass machining utilizes computer numerical control (CNC) technology to precisely mill and turn brass blanks to create complex parts. Brass, due to its excellent mechanical properties, electrical conductivity, and corrosion resistance, is a popular non-ferrous metal processing material in industries such as electronics, bathroom fixtures, and medical devices. We provide a one-stop CNC brass parts solution, from rapid prototyping to mass production.

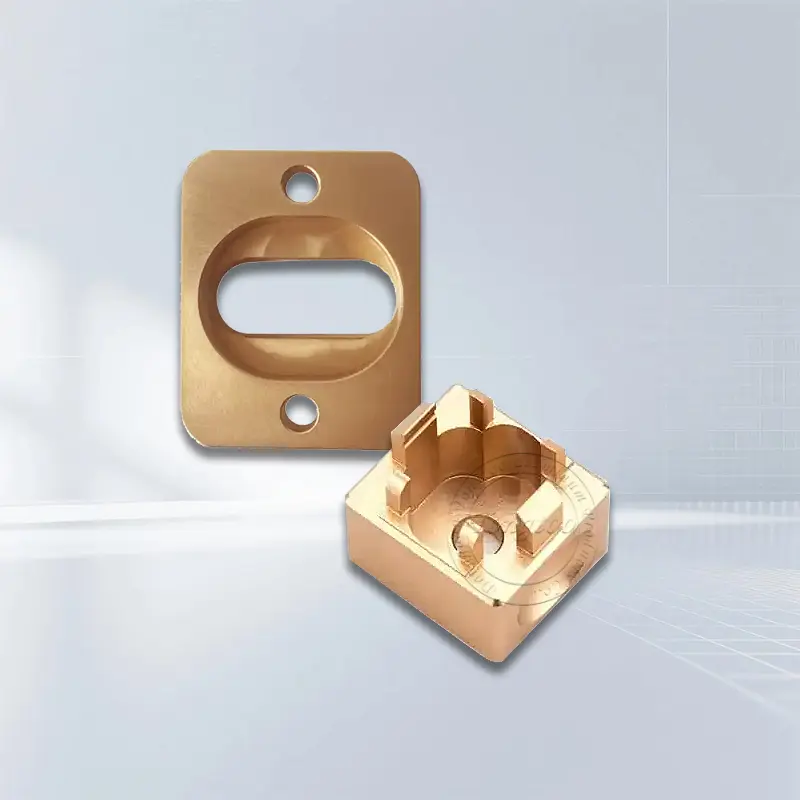

CNC Brass Parts Product Description:

Product Features and Applications of CNC Brass Parts

Machining Materials: Commonly used grades: H59, H62, H65, HPb59-1 (Easy Turning Brass), C36000 (Environmentally Friendly Free-Machining Brass), etc.

Material Properties: Excellent balance of strength, hardness, and ductility, enabling easy machining.

Machining Capabilities

Precision Range: Dimensional tolerances up to ±0.01mm, surface roughness up to Ra0.8.

Main Processes: CNC milling, CNC turning, mill-turning, drilling, tapping, etc. Post-Processing: We offer metal surface treatment services such as polishing, electroplating (nickel, chromium, silver), passivation, and sandblasting.

Core Features

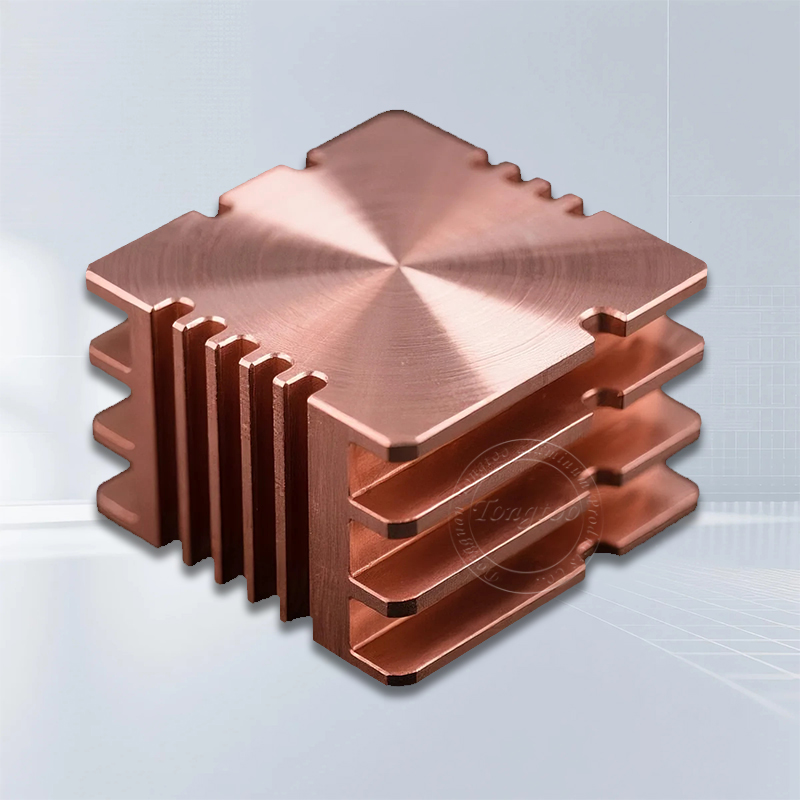

Excellent Electrical and Thermal Conductivity

Brass is an excellent conductor, making it an ideal material for electrical components such as electronic connectors and terminals, ensuring stable signal transmission.

Excellent Machinability

Brass, known as a "free-cutting metal," offers easy chip breaking and minimal tool wear during CNC machining, enabling high-speed machining, significantly improving production efficiency and reducing part manufacturing costs.

Excellent Corrosion and Wear Resistance

It offers excellent resistance to air, water, and various chemicals, making it particularly suitable for humid environments such as bathroom hardware and marine fittings.

It is self-lubricating and offers a long wear life.

Aesthetics and Hygiene

Brass surfaces can be easily polished or electroplated to a high-gloss finish, creating a premium metallic look. Its natural antibacterial properties make it a popular choice for medical device parts and consumer goods. High Strength and Durability

Compared to aluminum alloys and some plastics, brass parts offer higher structural strength and fatigue resistance, allowing them to withstand greater loads and maintain a longer service life.

Applications

Our CNC brass parts are widely used in various industries:

Electronic and Electronics Industry

Applications: RF connectors, terminal blocks, circuit board brackets, and electronic components.

Bathroom Hardware Industry

Applications: Faucet cartridges, high-end faucet bodies, showerhead internals, and pipe fittings.

Medical Device Industry

Applications: Surgical instrument handles, medical gas valves, and precision components for diagnostic equipment.

Consumer Goods and Lock Industry

Applications: High-end door lock cylinders, gears, watch parts, medals, and decorative items.

Industrial Equipment and Automotive Industry

Applications: Small-module gears, bearings, bushings, fuel system components, and sensor housings. Environmental Certifications:

RoHS Certification (lead-free, cadmium-free, and other hazardous substances)

REACH (European Union Chemical Safety Directive)

Quality Management System:

ISO 9001:2016/ISO 9001:2015 (production process quality control)

Testing Equipment: 3D Scanner (0.8μm accuracy)

Delivery, Shipping, and Serving

A professional ODM & OEM manufacturer with over 20 years of precision machining experience, we provide comprehensive, customized services tailored to customer needs.

|

|

|

Standard Packaging: Copy paper + carton

Custom Packaging: Blister tray/PEF + wooden box

Global Export Experience: Familiar with international packaging and shipping standards, we consistently supply products to global markets including Europe, America, Japan, and South Korea.

FAQ

Q1: What is the difference between CNC brass parts and die-cast brass parts?

A1: CNC-machined parts are cut from solid stock, resulting in a denser internal structure, higher strength, and far superior precision to die-cast parts. They are ideal for small-batch customization, complex structures, and high-performance parts. Die casting is more suitable for high-volume, relatively simple parts.

Q2: How do you address deformation issues in brass parts during production?

A2: We optimize CNC machining paths, control cutting parameters (such as speed and feed rate), and use specialized fixtures to effectively reduce cutting stress and heat buildup, thereby minimizing deformation and ensuring dimensional stability.

Q3: What surface treatments can you offer to enhance the performance of brass parts?

A3: In addition to aesthetically pleasing electroplating, we also offer passivation treatments to further enhance salt spray corrosion resistance, meeting the needs of outdoor or harsh environments.

Q4: Does your brass material meet environmental standards?

A4: Yes, we offer brass materials that comply with international environmental directives such as RoHS and Reach, such as C36000 environmentally friendly brass, ensuring our products are safe for use in global markets.

Q5: Can you quickly produce small batches or prototypes?

A5: Absolutely. Our CNC rapid prototyping service can provide you with samples within 1-3 days based on 3D drawings without the need for mold making, accelerating your product development and verification process.

Company Introduction

Our 5000㎡ workshop is equipped with hundreds of CNC machining centers (machining accuracy up to 0.002 MM), CNC lathes, milling machines, lathes, grinders, etc.; and over a dozen inspection equipment (inspection accuracy up to 0.001 MM), achieving internationally advanced machining capabilities. The Tengtu team possesses the most professional mold design and CNC machining knowledge. We will work closely with you throughout the prototyping, production, assembly, inspection, packaging, and final delivery processes to exceed your expectations.

Our team uses CNC machining to manufacture high-performance parts supporting industries such as aerospace, automotive, military, medical, machinery, electronics, and communications. We are committed to innovation, manufacturing and assembling critical components with superior precision, tight tolerances, and high-quality materials. Over the past 11 years, Tengtu has built a strong reputation for efficiency, quality, reliability, and on-time delivery.